DTF Printing: Unlock the Future of Digital Apparel Production

DTF printing, or Direct to Film printing, is revolutionizing the world of digital printing by offering cutting-edge solutions for custom apparel businesses. This innovative technology allows for high-resolution designs that can be seamlessly transferred onto a variety of fabrics, catering to the growing demand for personalized textile products. As companies strive to enhance their production efficiency while adopting sustainable printing practices, DTF printing emerges as a game changer, melding versatility and cost-effectiveness like never before. With its ability to produce vibrant and durable prints, DTF has become a preferred choice for brands looking to embrace textile printing innovations. This article delves deeper into how DTF printing reshapes the industry landscape, highlighting its numerous advantages and future potential.

Also known as Direct to Film technology, DTF printing represents a significant shift in how custom prints are produced within the textile market. This method combines the precision of digital printing with the practicality of film transfer, allowing for exceptional detail and color vibrancy in designs. Businesses across various sectors are beginning to adopt this custom print technology to meet the increasing consumer appetite for tailored products. With its emphasis on efficiency and sustainability, DTF printing not only enhances operational workflows but also aligns with the broader trends of eco-friendly practices within the printing industry. As we explore the capabilities of this innovative printing approach, we will uncover the ways it can empower businesses to thrive in a competitive marketplace.

Understanding DTF Printing Technology

Direct to Film (DTF) printing represents a paradigm shift in digital printing technology, providing a unique solution for creating custom designs on textiles. This innovative printing method enables businesses to produce vibrant graphics that adhere to a wide variety of fabrics, including cotton, polyester, and blends. By utilizing high-quality inks that fuse with the fabric, DTF ensures that every detail of intricate designs is accurately represented, achieving stunning results that appeal to customers looking for personalized apparel.

The process begins with the design being printed onto a special film, which is then transferred onto the selected textile material. What sets DTF apart from traditional methods is its capacity to eliminate the need for expensive setup costs often associated with screen printing. This accessibility allows smaller businesses to enter the custom printing market without heavy financial investments, thus broadening the scope of creative possibilities in fashion and merchandising.

The Benefits of DTF Printing

The advantages of DTF printing are manifold, primarily due to its versatility and efficiency. As the technology allows for printing on various materials and supports a wide range of color options, businesses can respond to diverse market demands swiftly. By streamlining production processes, DTF printing enables quicker turnaround times for custom orders, proving invaluable in today’s fast-paced retail environment, where consumers expect rapid fulfillment of unique products.

Additionally, DTF printing offers superior durability thanks to the quality of inks used. Once transferred, the prints are resistant to washing and fading, ensuring that the designs remain vibrant over time. As consumer trends lean towards sustainable practices, DTF’s ability to deliver high-quality, long-lasting prints aligns well with growing market expectations for durable and responsibly printed textiles.

Innovations in DTF Printing

Technological advancements are at the heart of the DTF printing revolution, making it easier for users to produce high-quality outputs. Innovations in printing head technology have significantly improved ink transfer mechanisms, enhancing the sharpness and vibrancy of prints. With developments in software, the user interface for many DTF printers has become increasingly intuitive, allowing those without prior printing experience to easily navigate the print processes.

Moreover, as sustainability in printing practices gains importance, manufacturers are focusing on developing eco-friendly inks and recyclable transfer films. This shift not only caters to environmentally conscious consumers but also positions DTF printers as viable options for businesses committed to reducing their ecological footprint, paving the way for green technology adoption in the industry.

Custom Applications of DTF Printing

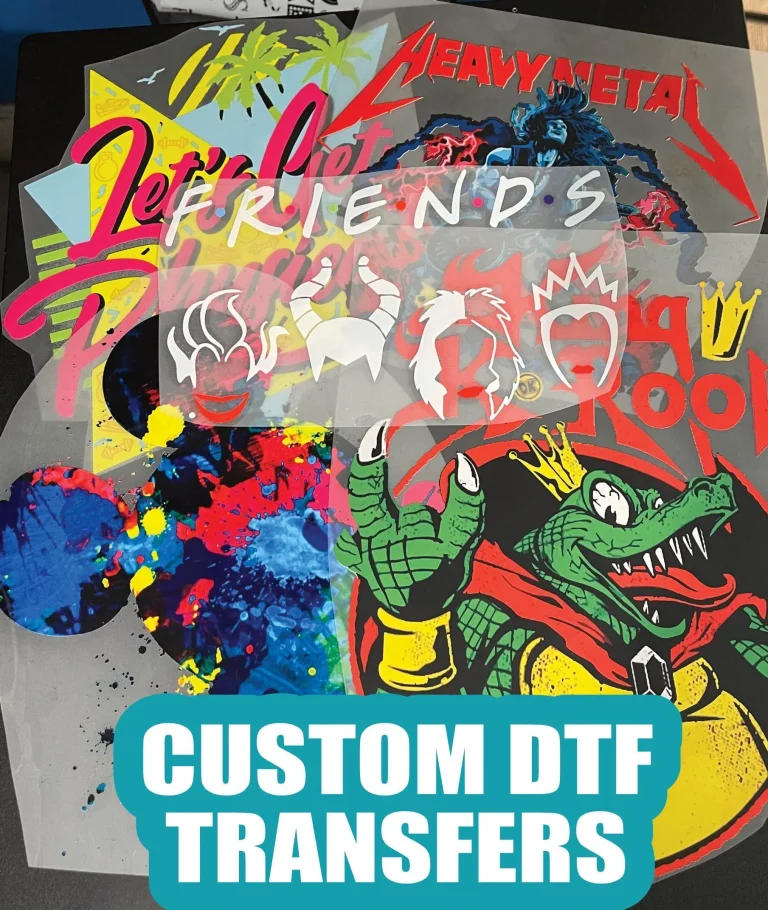

DTF printing opens a new world of possibilities for custom applications, extending beyond basic apparel to include personalized merchandise like bags, home textiles, and promotional goods. Its flexibility makes it a perfect choice for small businesses looking to differentiate themselves through unique product offerings that resonate with a wide audience.

Moreover, due to its capacity for detailed, full-color prints, DTF printing is gaining traction in niche markets, such as custom sportswear and event merchandise. The ability to create specialized designs tailored to specific themes or sentiments allows brands to engage with customers on a deeper level, establishing stronger connections and fostering brand loyalty.

The Future of DTF Printing: Trends and Predictions

As we look to the future, several trends are expected to shape the landscape of DTF printing. The integration of artificial intelligence into printing systems could enhance color matching processes and streamline project workflows. With AI’s data analysis capabilities, printers can maintain consistency across batches while also reducing waste and optimizing ink usage, contributing to cost-saving efficiencies.

Additionally, as consumer interest in customized and personalized products rises, we anticipate a corresponding growth in the adoption of DTF printing technology among retailers. This demand for bespoke items offers businesses an opportunity to stand out in a saturated marketplace, solidifying DTF as a front-runner in the digital printing growth segment.

Sustainable Practices in DTF Printing

In response to global calls for sustainability, the DTF printing industry is adopting various eco-friendly practices. Manufacturers are increasingly integrating water-based inks that minimize harmful emissions, alongside recyclable transfer films that drastically reduce waste. This commitment to sustainability not only aligns with consumer expectations but also reflects a broader industry trend toward responsible production methods.

Embracing sustainable practices in DTF printing allows businesses not only to differentiate themselves in the market but also to contribute positively to environmental conservation efforts. As more companies prioritize eco-conscious operations, the popularity of DTF printing as a green alternative is likely to increase, encouraging even more innovations in sustainable printing technology.

Frequently Asked Questions

What is the process of DTF printing in digital printing?

DTF printing, or Direct to Film printing, involves printing vibrant designs onto a specialized film which is then transferred to various fabric types. This technique utilizes unique inks that adhere well to both the film and the fabric, allowing for high-resolution prints that are durable and visually stunning. Unlike traditional digital printing methods, DTF printing is suited for a wider range of materials, making it a versatile choice for custom apparel.

How does DTF printing compare to traditional screen printing?

DTF printing offers several advantages over traditional screen printing, particularly in terms of cost and flexibility. With DTF, there is no need for expensive setup costs or lengthy production times associated with screen printing, making it ideal for small custom runs. The high-definition prints produced by DTF also capture intricate details and a broad color spectrum, providing superior quality while maintaining cost-effectiveness.

What materials can be printed using DTF printing technology?

DTF printing technology is versatile and can be used on various materials, including cotton, polyester, blends, and even intricate fabrics. This flexibility makes it suitable for a wide range of applications in both fashion and merchandise, accommodating different fabric types and custom print projects.

Why is DTF printing considered a sustainable printing practice?

DTF printing is considered a sustainable printing practice due to its use of water-based inks and recyclable films. The technology focuses on reducing environmental impact while maintaining high print quality, aligning with the growing demand for eco-friendly solutions in textile printing innovations.

What are some advantages of using DTF printing for custom apparel?

DTF printing offers numerous advantages for custom apparel, including versatility in fabric choice, high print quality with detailed designs, cost-effectiveness for small orders, durability against washing and wearing, and faster turnaround times. These factors make DTF a preferred choice for businesses looking to meet consumer demands for personalized and high-quality apparel.

What future trends can we expect with DTF printing technology?

Future trends in DTF printing technology may include the integration of artificial intelligence for enhanced color matching, growth in retail customization allowing for unique aesthetics, and an expansion of the global market as more businesses in developing countries adopt this cost-effective printing solution. These advancements will likely improve efficiency and consumer engagement in the DTF printing landscape.

| Key Feature | Description |

|---|---|

| What is DTF Printing? | A method for printing designs on films for transfer onto fabrics, suitable for various materials. |

| Versatility | Can print on diverse materials including cotton, polyester, and blends, making it flexible for different applications. |

| Quality and Detail | Allows high-definition prints capturing intricate details and a wide color spectrum for stunning designs. |

| Cost-Effectiveness | Minimizes costs, especially for small runs, by eliminating expensive screen setups. |

| Durability | Uses inks designed to endure washing and wearing, resistant to fading and peeling. |

| Faster Turnaround Times | Quicker production times due to the efficiency of DTF, ideal for today’s fast-paced market. |

| Technological Advancements | Includes enhanced printing heads and user-friendly interfaces to improve quality and accessibility. |

| Eco-Friendly Options | Utilizes water-based inks and recyclable films to reduce environmental impact during production. |

| Future Trends | Integration with AI for better color matching and growth in retail customization for unique designs. |

| Global Market Expansion | Increased accessibility in developing countries where businesses are seeking cost-effective printing solutions. |

Summary

DTF printing is revolutionizing the world of digital printing, known for its quality, efficiency, and versatility across various fabric types. This innovative method allows for vibrant, high-resolution designs to be transferred onto garments, catering to growing consumer demands for personalized products. With its cost-effectiveness and durability, DTF printing has become an essential solution for businesses looking to enhance productivity while maintaining quality standards. As technology advances, including the integration of AI and sustainable practices, the future of DTF printing looks promising, positioning it as a leader in the customization and textile market.