DTF printing trends shaping the future of gangsheet builders

DTF printing trends are reshaping the landscape of garment decoration, delivering vibrant color palettes, broad substrate compatibility, and scalable production workflows that empower brands to meet rising demand with speed and consistency, whether serving a single custom order, managing on-demand drops for online storefronts, or coordinating multi-SKU launches across regional networks while maintaining uniform print quality, color stability, and predictable post-press performance across diverse fabrics and finishes. In practice, this shift is underpinned by tools like the DTF gangsheet builder, which lets studios lay out dozens—sometimes scores—of transfers on a single sheet to maximize throughput, minimize ink waste, and dramatically reduce prepress time, aided by grid-based layouts, auto-spacing, artwork imports, dynamic bleed controls, cross-sheet alignment verification, and seamless export to printer-ready sheets that align perfectly with sheet sizes and press cadences. DTF technology trends are driving tighter color fidelity through smarter color management, automated imposition, real-time validation, and deeper integration between design software, RIPs, and printer firmware, all of which contribute to more predictable results and fewer proofs across production runs, while dashboards track color drift, ink usage, and uptime to inform continuous improvement. Direct-to-film innovations are broadening substrate options and improving adhesion on blends and synthetics, boosting durability via refined coating chemistries, offering more forgiving handling in production, and enabling new product lines—from performance fabrics to fashion-forward knits—without compromising print quality or wash performance, as film formulations become more compatible with heat-settings and finishing processes used in common garment finishing lines. As shops adopt these capabilities, they emphasize sustainability, cost control, and ongoing education to maximize return on investment, ensure consistent color and compliance across batches, and build resilient workflows that scale with demand while supporting responsible material choices, robust supplier validation, and ongoing optimization through data-driven feedback loops.

In other words, this approach centers on moving designs from a printable film onto textiles via heat, a method often called film-to-fabric transfer or ink-on-film decoration. From an LSI perspective, related concepts include digital fabric printing, transfer-based apparel decoration, and on-demand garment customization, all signaling a shift toward flexible production and rapid reprints. As the ecosystem evolves, manufacturers emphasize workflow automation, color integrity, and substrate versatility, ensuring that brands can deliver high-impact visuals across a range of fabrics with consistent results.

DTF printing trends: Automation, Color Fidelity, and Workflow Integration

Automation and integrated workflows are reshaping how shops move from design to finished transfers. End-to-end workflows connect design software, the gangsheet layout tool, printer firmware, and post-print processing to reduce human error, speed prep, and ensure color stability across runs. As vendors expand seamless integrations with popular design platforms and automated imposition for gang sheets, the industry is seeing faster setup times and more scalable business models driven by DTF printing trends.

Advances in color fidelity and white ink performance are enabling bolder designs with crisper details and smoother gradients. Improved white ink formulations, higher-density print capabilities, and smarter color management cut trial-and-error proofing, leading to less waste and more consistent expectations for clients. These improvements, together with direct-to-film innovations and evolving DTF technology trends, help shops deliver vivid transfers with reliable results across a wider range of fabrics.

Maximizing Throughput with the DTF Gangsheet Builder: Substrates, Cost Control, and Sustainability

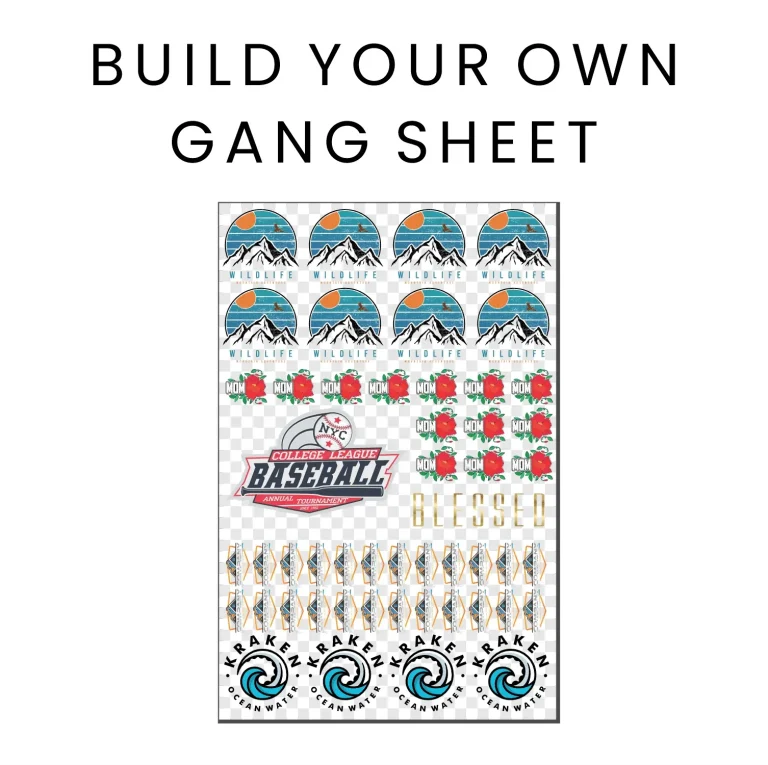

The DTF gangsheet builder is a strategic tool for maximizing sheet capacity and throughput. By laying out multiple transfers on a single sheet, shops reduce material waste, shorten setup times, and lower unit costs—especially on large or mixed orders. This capability not only accelerates production but also improves consistency across DTF transfers, making the gangsheet builder a central component of efficient, scalable workflows.

Beyond efficiency, the gangsheet approach supports broader substrate versatility and sustainability goals. With new coatings and film chemistries, printers can tackle blends, performance fabrics, and even non-traditional textiles while maintaining adhesion and wash durability. The ability to manage precise ink placement and heat settings across varied materials also aligns with cost control objectives, enabling eco-friendly practices and a more resilient business model in an era of evolving direct-to-film innovations and industry-wide DTF technology trends.

Frequently Asked Questions

How are DTF technology trends affecting the use of the DTF gangsheet builder to increase throughput and reduce waste?

DTF technology trends are driving automation and integrated workflows, making the DTF gangsheet builder essential. By laying out multiple designs on a single sheet, shops boost press uptime, lower material waste, and reduce unit costs. Improved color fidelity and smarter white ink management also help maintain consistent DTF transfers across orders, supporting faster turnarounds and stronger profitability.

With ongoing DTF printing trends and substrate innovations, how can shops expand product versatility and maintain quality when printing on diverse materials using the gangsheet builder?

Material versatility and direct-to-film innovations are expanding the range of substrates—from cotton blends to performance fabrics and new coatings. The DTF gangsheet builder helps optimize ink placement and heat settings across varied materials, reducing setup time and waste while preserving color accuracy in DTF transfers. This supports cost control, sustainability, and a broader product lineup.

| Key Point | Summary |

|---|---|

| What is DTF printing and why it matters | DTF prints designs onto a removable film and transfers them to textiles using heat; it offers high color vibrancy, durability, broad substrate compatibility, and a simpler workflow—well suited for on-demand runs, customization, and quick reprints. |

| The role of the DTF gangsheet builder in modern workflows | A gangsheet builder arranges multiple designs on a single sheet to maximize throughput, reduce material waste, and lower unit costs; it’s a strategic tool that influences throughput, lead times, and profitability. |

| Automation and integrated workflows | End-to-end workflows connect design software, the gangsheet layout tool, printer firmware, and post-processing to reduce errors, speed prep, and ensure color consistency; vendors offer smoother integrations and automated imposition. |

| Color fidelity and white ink improvements | Improvements in white ink and color management yield crisper details and smoother gradients; better profiles and libraries reduce trial runs, waste, and client dissatisfaction. |

| Material versatility and coatings | Emphasis on blends, performance fabrics, and some synthetics; new coatings and transfer films improve adhesion, wash durability, and stretch; gangsheet tooling helps manage varied substrates. |

| Direct-to-film innovations and substrates | Improvements in film translucency, adhesive chemistry, and clear coatings broaden print options to more fabrics and non-traditional textiles, enabling sharper imagery. |

| Cost control and sustainability | Strategies to reduce waste, optimize consumables, and extend equipment life; gangsheet consolidation lowers changes; recyclable or refillable inks/films are increasingly adopted. |

| Education, support, and community knowledge sharing | DTF communities grow through training, forums, and vendor support; shared best practices shorten learning curves and accelerate trend adoption. |

| Why printers should watch DTF technology trends | DTF technology trends point to more predictable production, greater automation, and broader substrate compatibility; faster turnarounds, lower unit costs, and more consistent results are achievable as the gangsheet builder enables efficient WIP management. |

| Practical guidance for adopting these trends in your shop | Assess your current workflow; invest in a capable gangsheet builder; prioritize color management; pilot new substrates; track costs and waste; train your team; focus on sustainability. |

| The business case for embracing DTF printing trends | A robust gangsheet workflow enables a wider product range, faster delivery, higher fidelity, and preserved margins as demand grows. |

| Case examples and practical outcomes | Boutique shops cut lead times; mid-sized shops reduce film waste and per‑unit costs; online retailers enable on-demand drops with consistent color across fabrics. |

| Conclusion | Future of DTF printing trends is guided by smarter workflows, advanced materials, and stronger substrate support. The DTF gangsheet builder remains central to higher throughput, lower waste, and tighter production control. By embracing automation, enhanced color management, and sustainable practices, shops can deliver durable, high‑fidelity designs that meet evolving customer expectations and unlock opportunities in on‑demand apparel and beyond. |

Summary

DTF printing trends are shaping the future of apparel production by accelerating automation, expanding substrate options, and enhancing color accuracy. A modern workflow centered on the DTF gangsheet builder enables higher throughput, lower waste, and tighter production control, supporting faster turnarounds and scalable growth. By embracing automation, refined color management, sustainable materials, and continual skill-building, shops can deliver durable, high‑fidelity designs that meet evolving customer expectations and open opportunities in on‑demand apparel and beyond.