DTF Printing: The Ultimate Guide You Need for 2025

DTF printing, short for Direct to Film printing, is revolutionizing the textile and printing industries with its ability to produce stunning, high-quality images on a variety of fabrics. This innovative DTF printing technology has gained popularity among designers, thanks to its remarkable versatility, which allows for vibrant prints on materials ranging from cotton to polyester blends. Utilizing a unique gang sheet technique, this printing method not only optimizes material use but also enhances production efficiency, making it a first choice for businesses looking to reduce waste and costs. As 2025 approaches, the importance of DTF printing continues to grow, emphasizing the demand for customization in DTF printing projects across various applications, including apparel and promotional items. Understanding the benefits and processes involved in DTF printing will be essential for those aiming to harness its full potential in a competitive market.

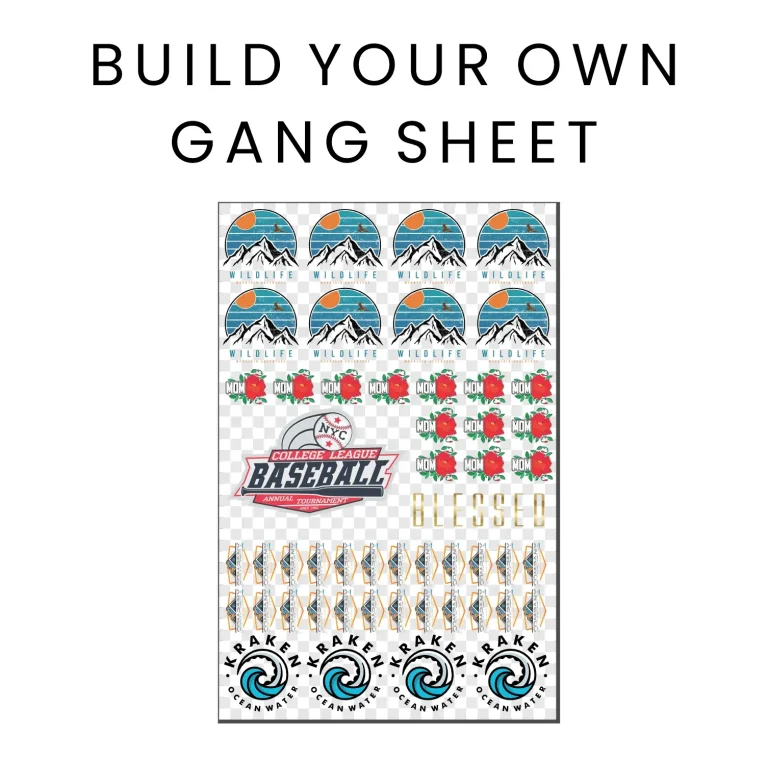

Direct to Film printing, often abbreviated as DTF, is gaining traction among a diverse array of industries seeking cutting-edge printing solutions. This advanced form of printing technology allows creators to apply intricate designs onto numerous fabric types, opening doors to an exciting realm of imaginative possibilities. One of its standout features is the ability to produce multiple designs simultaneously through the gang sheet technique, which supports efficient resource management and minimizes waste. As the printing landscape evolves, customization in direct film printing becomes increasingly important, allowing brands to cater to specific consumer preferences and trends. Embracing this innovative approach not only elevates product quality but also positions businesses favorably in an ever-changing marketplace.

Understanding DTF Printing Technology

DTF printing technology, which stands for Direct to Film printing, revolutionizes the traditional printing landscape by utilizing a unique transfer method. This process involves printing images on a special PET film with specially formulated inks that allow for vibrant and detailed outputs. After printing, the film is heat-pressed onto the fabric, enabling a seamless and rugged bond. This technique is not only advantageous for producing complex designs but also accommodates fabrics such as cotton, polyester, and blends, making DTF printing a versatile solution for various applications.

One primary advantage of DTF printing over other methods, like Direct-to-Garment (DTG) printing, is that it requires less preparation time and can be applied to a wider range of materials. This means that small businesses or start-ups can create customized products without worrying about the limitations of fabric types, while also maintaining print quality and durability. As the industry progresses, DTF printing technology continues to evolve, providing users with more options for creativity and expression in their work.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is a process where designs are printed onto a special PET film and then heat-pressed onto fabric. This technique allows for vibrant, intricate designs on various materials including cotton and polyester.

How does the gang sheet technique enhance DTF printing efficiency?

The gang sheet technique in DTF printing optimizes material usage by allowing multiple designs to be printed on a single film. This reduces waste and lowers production costs, making it ideal for both small and large scale operations.

What advancements in DTF printing technology have emerged by 2025?

By 2025, DTF printing technology has seen advancements such as nine-color systems for enhanced color vibrancy and roll-to-roll printing for faster production. These innovations improve efficiency and quality in high-volume printing.

What types of materials can DTF printing work with?

DTF printing offers versatility with an array of materials, including leather, canvas, and outdoor fabrics. This broadens the scope for creative applications such as apparel, home decor, and promotional items.

How is customization applied in DTF printing?

Customization in DTF printing allows businesses to create personalized items, tapping into the growing market for bespoke products. This includes custom apparel, cushions, mugs, and banners, providing unique branding opportunities.

What is the future outlook for the DTF printing industry?

The future of the DTF printing industry looks bright as consumer demand for customization and rapid production continues to rise. Events like DTF Expo 2025 will further propel innovation and market opportunities, making DTF a vital component in modern printing.

| Key Aspect | Details |

|---|---|

| Definition | DTF printing is a process that prints designs onto PET film, which is then heat-pressed onto fabric. |

| Advantages | Applies to a greater variety of materials and produces vibrant prints. |

| Gang Sheet Technique | Maximizes efficiency by allowing printing multiple images on one film, reducing waste and costs. |

| Technological Advancements | Introduces nine-color systems and roll-to-roll printing for better productivity and quality. |

| Material Versatility | Can work with various materials including leather, canvas, and outdoor fabrics. |

| Market Trends | Growing consumer demand for customization and rapid turnaround is driving the market. |

| Integration with Other Technologies | Combining DTF with DTG and UV printing enhances product quality. |

Summary

DTF printing is revolutionizing the printing industry by combining advanced technology and material versatility, offering high-quality prints that cater to a wide range of applications. With its unique benefits over traditional methods, DTF printing continues to grow in popularity among designers and businesses alike. As more innovations emerge, such as the gang sheet technique and enhanced ink adhesion, DTF printing is poised to meet the rising consumer demand for customized products efficiently. By understanding the capabilities and potential of DTF printing, stakeholders can position themselves at the forefront of this dynamic market, creating unique offerings that stand out in today’s competitive landscape.