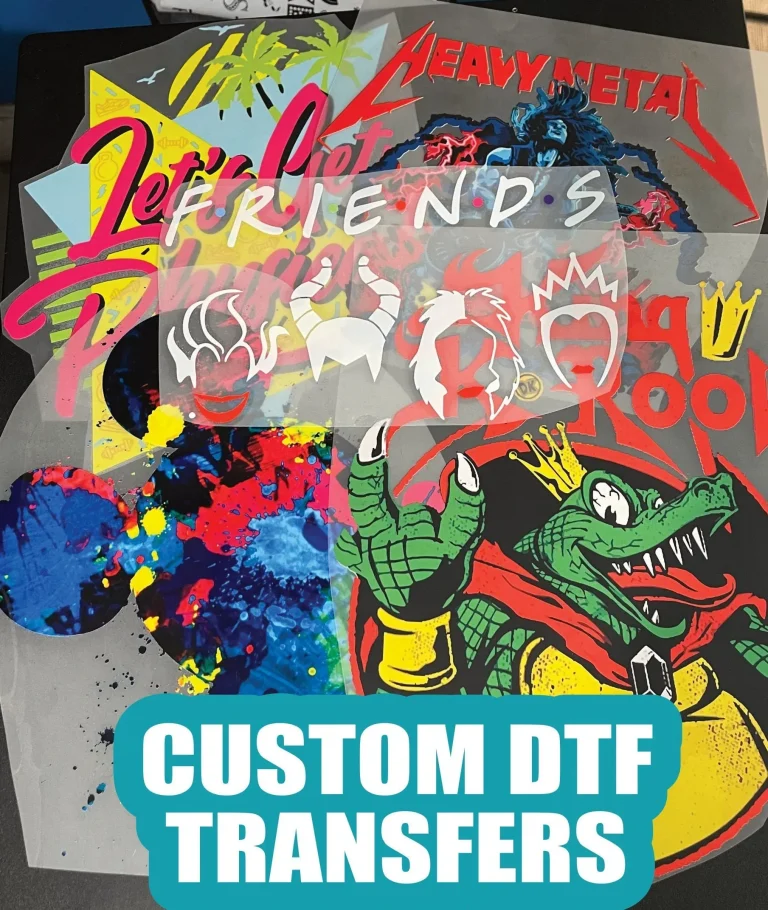

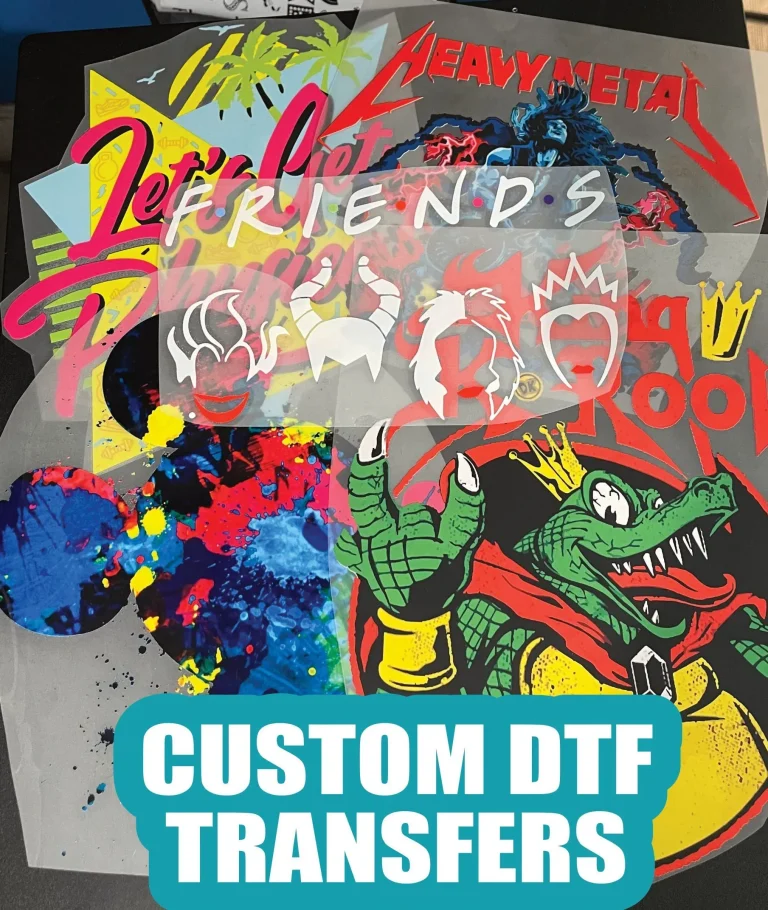

DTF Printing: The Future of Textile Printing Explained

DTF printing, or Direct to Film printing, is revolutionizing the textile printing industry by providing an advanced method for creating high-quality designs on garments. This innovative technology enables businesses to achieve stunning visuals with vibrant colors on various fabric types, a feat that has become essential in today’s competitive market. The advantages of DTF printing include versatility, durability, and cost-effectiveness, making it the go-to solution for garment customization and personalization. As the demand for unique and tailor-made fashion solutions grows, DTF printing stands poised to shape the future of textile printing technology significantly. In this post, we will explore the various aspects of DTF printing, from its benefits to its evolving role in the industry.

In the realm of textile decoration, Direct to Film printing (DTF) represents a new approach that emphasizes efficient and high-quality results. This garment decoration method not only bridges the gap between traditional and modern printing techniques but also offers numerous advantages for businesses and consumers alike. With an increasing focus on personalization in fashion, DTF offers solutions that cater to the unique preferences of today’s buyers. By leveraging advanced technology, Direct to Film printing enhances the ability to produce vibrant and intricate designs on a wide array of fabrics, setting the stage for a flourishing market. As we navigate through the details of this textile printing innovation, it becomes clear that DTF could very well define the future landscape of garment customization.

Understanding the DTF Printing Process

DTF printing stands out as a revolutionary textile printing technology that bridges the gap between high-quality design and efficient production methods. The process begins with printing captivating graphics onto a special PET film using innovative inks, which are often water-based and recognized for their environmental friendliness. This meticulous approach ensures that each design captures the vibrancy and intricacies needed for stunning garment visuals. Following the printing stage, the film is then transferred onto the fabric using heat and pressure, resulting in a durable and flexible design that seamlessly integrates with various textile materials.

One of the standout features of DTF printing is its exceptional versatility, enabling it to handle a wide range of fabrics, from cotton to polyester and blends. This adaptability makes it ideal for businesses looking to produce diverse apparel items, from casual t-shirts to high-performance athletic wear. Furthermore, the ability to print on both light and dark substrates with consistent quality addresses a significant demand in the market, allowing for personalized prints that cater to individual customer preferences.

The Key Advantages of DTF Printing

DTF printing offers several distinct advantages that set it apart from traditional printing techniques such as screen printing and direct-to-garment (DTG) printing. One of the primary benefits is its cost-effectiveness; the initial investment is relatively lower, and the reduction in material waste during production means higher profitability for businesses. Additionally, the print quality achieved through DTF technology is remarkable—high-resolution designs flourish with vibrant colors that endure through multiple washes, ensuring customer satisfaction and repeat business.

Another significant advantage is the speed of production. DTF printing processes are streamlined, enabling quicker setups and rapid turnaround times. This efficiency caters well to the growing trend of on-demand garment customization, where businesses can pivot quickly to meet evolving consumer desires. In an industry where time is of the essence, the ability to produce high-quality products swiftly places DTF printing ahead of traditional methods.

Emerging Trends in DTF Technology

As the DTF printing industry evolves, numerous emerging trends signal its future trajectory. Technological advancements are leading to the development of improved ink formulations and transfer films, which enhance not only the quality but the longevity of the printed designs. Manufacturers are also focusing on incorporating eco-friendly inks into their offerings, adhering to the rising standards of sustainability in fashion. This reflects a significant shift in consumer mindset, as buyers increasingly prioritize products that are not just aesthetically pleasing but also environmentally responsible.

Additionally, the integration of digital solutions into DTF printing processes is enhancing operational efficiency. Automation technologies are being explored to optimize production flow, minimizing human error and maximizing output. This shift toward increased automation contributes to making DTF printing a more viable option for both small businesses and large-scale manufacturers, enabling them to meet demand while staying competitive in the market.

Challenges and Solutions in DTF Printing Adoption

Despite its many advantages, adopting DTF printing is not without challenges. New entrants to the textile printing market may find the initial investment in specialized equipment daunting. This barrier can deter potential entrepreneurs who might feel overwhelmed by the financial commitment required to establish a reliable DTF printing setup. Moreover, as the technology is still relatively new, businesses may struggle with ensuring consistent print quality across production runs, leading to variability that can affect customer trust and product satisfaction.

Fortunately, several solutions and innovations are emerging to address these challenges. For instance, financing options or leasing arrangements for equipment could alleviate some of the initial financial burdens for startups. Additionally, as more professionals enter the industry, training programs and resources dedicated to mastering DTF printing will likely proliferate, equipping personnel with the necessary skills to maintain high-quality outputs consistently.

Exploring the Future of DTF Printing

Looking ahead, the future of DTF printing seems incredibly bright, with expectations of increased adoption and innovation. Industry experts predict that the focus on customization will continue to rise, propelling DTF printing to the forefront of garment decoration methods. As consumer preferences shift towards personalized and unique fashion items, businesses that embrace DTF technology will likely find themselves well-positioned to thrive in this competitive landscape.

Moreover, the integration of artificial intelligence and machine learning into DTF printing processes could revolutionize how designs are created and printed. These technologies promise to enhance the ability to quickly adapt to trends and customer preferences, ensuring that businesses can remain agile and responsive. In conjunction with eco-friendly practices and sustainable materials, the future of DTF printing appears aligned with the ethos of modern consumers, prioritizing quality, personalization, and environmental responsibility.

Frequently Asked Questions

What are the main advantages of DTF printing in textile customization?

DTF printing, or Direct to Film printing, offers several advantages for textile customization, including high-resolution prints, vibrant colors, and durability on various fabric types. Its versatility allows it to print on both light and dark garments effectively, catering to a wide range of consumer preferences. Additionally, DTF printing provides quicker production times and is more cost-effective compared to traditional methods.

How does DTF printing differ from traditional textile printing methods?

Unlike traditional textile printing methods like screen printing and direct-to-garment (DTG) printing, DTF printing transfers images from a PET film to the garment, resulting in vibrant colors and detailed designs. This method is adaptable to a variety of fabrics and allows for faster setups and reduced material waste, making it a preferred choice for personalized garment decoration.

What types of fabrics are compatible with DTF printing technology?

DTF printing is compatible with a wide range of fabrics, including cotton, polyester, and blended textiles. This flexibility makes it an ideal option for businesses looking to produce high-quality custom apparel across different garment types, enhancing its appeal in the textile printing industry.

What is the future outlook for DTF printing in the textile industry?

The future of DTF printing looks promising, as it continues to evolve with technological advancements. Experts predict its integration into custom apparel shops will increase due to its quality, adaptability, and responsiveness to consumer trends for personalization and sustainable practices, solidifying DTF’s position in the textile printing landscape.

Can DTF printing technology accommodate eco-friendly practices?

Yes, DTF printing technology increasingly incorporates eco-friendly inks and materials, addressing the growing demand for sustainable practices in the textile industry. As consumers prioritize environmental concerns, businesses utilizing sustainable DTF solutions can gain a competitive edge while meeting modern consumer expectations.

What challenges do businesses face when adopting DTF printing?

Businesses venturing into DTF printing may encounter challenges such as the need for specialized equipment and skilled personnel, which can result in high startup costs. Additionally, achieving consistent print quality can be difficult as the technology is still developing. However, innovations are anticipated to address these challenges, enhancing accessibility and reliability in the DTF printing process.

| Key Point | Description |

|---|---|

| What is DTF Printing? | DTF printing transfers high-quality designs onto fabric from a specially coated film, enabling vibrant and intricate designs on various materials. |

| Market Growth and Trends | The demand for personalized apparel is driving the DTF printing market’s growth, making it a popular choice among businesses. |

| Advantages Over Traditional Methods | DTF offers versatility, quality, speed, and cost-effectiveness compared to conventional methods like screen printing & DTG. |

| Technological Advancements | Innovations in DTF technology improve adhesion, durability, and sustainability, with eco-friendly options being developed. |

| Future Outlook | DTF is expected to gain traction in custom apparel production due to its adaptability and efficiency, overcoming existing challenges. |

| Challenges in Adoption | Barriers such as the need for specialized equipment and skills can hinder the adoption of DTF printing for new businesses. |

Summary

DTF printing is revolutionizing the textile printing industry with its ability to produce high-quality, vibrant designs on various fabric types. This innovative technology not only addresses the growing demand for personalization but also offers a competitive edge through its versatility and cost-effectiveness. As businesses seek to enhance their garment decoration processes, DTF printing emerges as a leader, catering to diverse consumer preferences and sustainability trends. With ongoing advancements in technology and materials, the future of DTF printing looks promising, positioning it as a crucial player in the evolving landscape of textile printing.