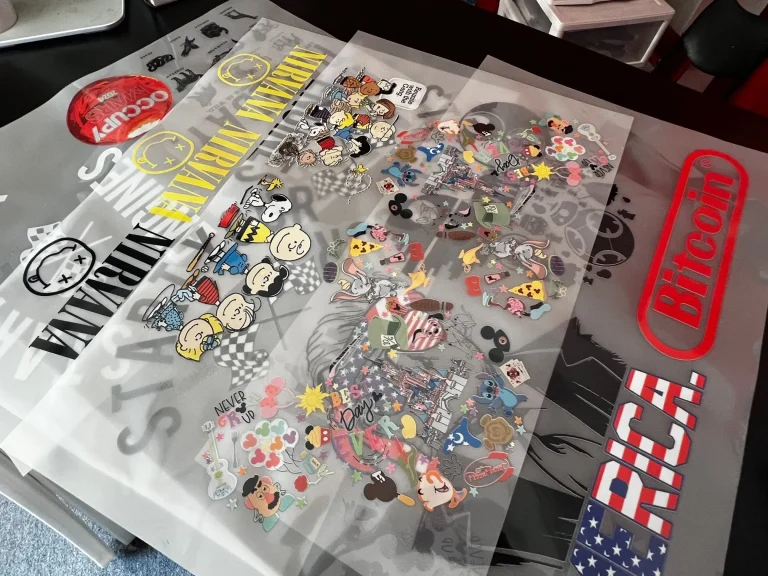

DTF Printing: The Future of Custom Apparel Revealed

DTF printing, short for Direct-to-Film printing, is revolutionizing the custom apparel industry with its innovative approach to transferring designs onto fabrics. This cutting-edge technique not only emphasizes vibrant and durable prints but also aligns with the growing demand for sustainable printing technologies. Unlike traditional methods, DTF offers unparalleled flexibility and accuracy, making it a preferred choice for fashion brands seeking to stay ahead of apparel manufacturing trends. As businesses increasingly weigh the benefits of DTF vs sublimation, this method stands out with its ability to cater to diverse fabric choices and complex designs. Join us as we explore the future of custom apparel and the integral role that DTF printing is set to play in it.

Often referred to as direct-to-film printing, DTF printing represents a significant advancement in custom clothing production that allows for detailed and vibrant designs to be seamlessly applied to various fabrics. This technique has gained traction in recent years, driven by a desire for sustainable practices within the printing industry. With its ability to reduce waste and utilize non-toxic materials, it’s reshaping how designers approach fabric printing. Additionally, comparisons between DTF and alternatives like sublimation demonstrate a clear advantage in terms of versatility and application across fabric types. As we navigate current apparel manufacturing trends, understanding alternatives like DTF will be crucial for anyone involved in the fashion or textiles sector.

The Role of Direct-to-Film Printing in Custom Apparel

Direct-to-Film (DTF) printing represents a transformative leap in the realm of custom apparel. By enabling designers to translate intricate graphics and vibrant colors directly onto films, this method serves as a game changer for businesses seeking high-quality, detailed prints. Unlike traditional methods, DTF shifts the focus from the printing substrate to the film, capturing the essence of the design with unparalleled precision. This innovation not only enhances the visual appeal but also ensures durability and wash resistance, qualities that consumers increasingly demand.

Moreover, DTF printing stands out in its versatility across various fabric types, ranging from cotton to more unconventional blends. This flexibility allows apparel manufacturers to expand their offerings, catering to diverse consumer preferences in style and fabric choices. As fashion trends continue to evolve, the ability of DTF to accommodate multiple substrates ensures that brands can remain relevant and competitive in a dynamic market.

Advantages of Sustainable Printing Technologies

Sustainability has emerged as a vital consideration in the apparel industry, driving brands to adopt environmentally-friendly printing processes. Sustainable printing technologies, including DTF printing, reduce waste and minimize environmental impact significantly. Traditional methods often involve excess material usage and toxic chemicals, while DTF printing utilizes non-toxic inks and produces fewer emissions during production. This shift not only appeals to eco-conscious consumers but also reinforces a brand’s commitment to sustainable practices.

In addition, sustainable printing technologies emphasize efficiency in resource use. Techniques like DTF printing typically require less water and energy compared to methods such as dye sublimation. This reduction in resource consumption helps lower overall production costs, allowing companies to allocate funds towards improving their sustainability initiatives or investing in new design technology.

DTF vs. Sublimation: A Comprehensive Comparison

In the ongoing debate between DTF printing and dye sublimation, each method has its unique strengths. DTF printing is particularly advantageous for its broader range of fabric compatibility. While sublimation requires a polyester surface for optimal results, DTF can print effectively on various materials, including natural fibers. This aspect positions DTF as a more versatile option for brands that wish to experiment with different fabrics and textures, appealing to a wider audience.

Furthermore, when examining design capabilities, DTF printing excels in producing vibrant colors and detailed graphics. The layering process in DTF allows artists to create complex designs with gradients and shadows that might be challenging to achieve with sublimation. As brands strive for creative differentiation within a crowded marketplace, the flexibility and detail provided by DTF can make all the difference.

Emerging Trends in Apparel Manufacturing

As the landscape of apparel manufacturing evolves, embracing advanced printing technologies like DTF is becoming increasingly crucial for staying competitive. Market trends indicate a growing inclination toward personalization and customization, with consumers seeking unique apparel that reflects their individual styles. DTF printing caters to this demand by enabling small businesses and crafters to create personalized designs without the hefty investment typically associated with traditional printing methods.

Moreover, the trend towards sustainable production methods is shaping the future of apparel manufacturing. Brands that adopt DTF printing demonstrate a commitment to eco-friendly practices, striking a balance between innovation and environmental responsibility. This alignment not only appeals to the modern consumer but also positions manufacturers favorably in a market that is progressively valuing sustainability.

How DTF Printing Empowers Crafters and Small Businesses

The rise of DTF printing technology has opened new avenues for creativity among crafters and small business owners. With user-friendly printing options, individuals can now transform their creative ideas into wearable art with minimal hassle. This democratization of the custom apparel market enables artisans and entrepreneurs to produce high-quality garments without the barrier of substantial upfront equipment costs.

Moreover, the customization features offered by DTF printing mean that small businesses can cater to niche markets, producing limited edition items that resonate with their audience. This level of customizability not only satisfies consumer desires for unique products but also helps smaller brands to establish a distinct identity in a saturated market.

The Future of Custom Apparel: Trends and Innovations

Looking ahead, the future of custom apparel is promising with advancements in technologies like DTF printing at the forefront. Brands are increasingly integrating smart technologies and automated processes into their production lines, allowing for quicker turnarounds and enhanced efficiency. As this trend continues, DTF printing will play a crucial role in streamlining operations while maintaining high quality.

Additionally, the incorporation of artificial intelligence in design processes might further revolutionize how brands create and offer custom apparel. By marrying technology with art, businesses can respond swiftly to changing consumer preferences while also simplifying the design process. Thus, DTF printing stands as a pivotal element in shaping an agile and responsive landscape in the world of custom apparel.

Frequently Asked Questions

What is DTF printing and how does it work in custom apparel printing?

DTF printing, or Direct-to-Film printing, is a method that transfers designs onto fabrics using a special film. The designs are printed on the film and then heat-pressed onto the garment. This technique allows for vibrant, durable prints on various fabric types, making it an ideal choice for custom apparel printing.

How does DTF printing compare to sublimation in the apparel manufacturing industry?

DTF printing offers greater flexibility than sublimation, as it can be used on a wider range of fabrics beyond just polyester. Additionally, DTF supports intricate designs and a broader color palette, making it a preferred option for brands looking to create unique custom apparel.

What are the sustainability advantages of using DTF printing technologies?

DTF printing is considered more sustainable than traditional methods, as it reduces waste by minimizing excess inks and materials. It also uses significantly less water and relies on non-toxic inks, contributing to a greener apparel manufacturing process.

Can DTF printing accommodate the latest trends in custom apparel?

Yes, DTF printing is at the forefront of apparel manufacturing trends. Its ability to produce high-quality prints quickly and cost-effectively allows brands to respond swiftly to market demands for personalized and unique fashion pieces.

What new services are emerging in the DTF printing market for crafters?

As DTF printing grows, new services like those from DTFPrinter are designed specifically for crafters and small businesses. These services streamline the printing process, allowing users to focus on creative designs while easily producing custom apparel without significant investment in equipment.

Why should businesses invest in DTF printing technology for custom apparel?

Investing in DTF printing technology positions businesses to offer high-quality, versatile, and eco-friendly custom apparel. The rapid expansion of DTF capabilities meets the increasing consumer demand for innovative designs, making it a competitive advantage in the printing industry.

| Key Point | Details |

|---|---|

| What is DTF Printing? | A method of transferring designs onto fabrics using special film and heat pressing, resulting in vibrant, durable prints with design flexibility. |

| Sustainability Advantages | Reduces waste and water consumption, uses non-toxic materials, and is considered environmentally friendly compared to traditional methods. |

| Market Expansion | Rapid growth with investments in production capacity, allowing for large-format printing and quick, high-quality outputs. |

| New Services for Crafters | User-friendly services launching for small businesses and individual creatives, simplifying the custom print process. |

| Comparison to Other Methods | DTF offers more fabric flexibility and supports complex designs better than traditional sublimation printing. |

Summary

DTF printing is revolutionizing the world of custom apparel as it introduces innovative solutions for sustainability, speed, and creative flexibility. With its ability to produce high-quality prints on a wide array of fabrics using environmentally friendly processes, DTF printing is gaining traction among businesses and crafters alike. As the technology evolves, it opens up numerous opportunities for customization and responsiveness to market demands, ensuring that it will be an integral part of the fashion industry’s future. Brands looking to appeal to eco-conscious consumers will find DTF printing to be a game-changing method that combines style with responsibility.