DTF Printing: The Comprehensive Guide from Concept to Creation

DTF printing, or Direct-to-Film printing, has swiftly gained recognition in the textile printing world as a game-changer for businesses seeking superior quality and efficiency in custom apparel printing. This innovative technology simplifies the printing process while delivering vibrant and long-lasting results, appealing to both small startups and established brands. As we delve into the DTF printing process, we will uncover its myriad advantages, the latest developments in DTF printing technology, and how it is transforming the landscape of garment customization. With a growing demand for personalized designs and rapid production times, understanding the ins and outs of DTF printing is essential for anyone involved in the fabric industry. Join us as we explore the unique aspects that make DTF a preferred choice among modern printing solutions.

Direct-to-Film (DTF) printing represents a revolutionary approach to textile design, enabling creators to transfer intricate graphics onto fabric with remarkable ease. Often referred to as DTF transfer printing, this technique harnesses advanced printing technology and a heat-pressing method that sets it apart from traditional printing options. Perfect for custom apparel printing, the DTF printing process is gaining traction due to its flexibility and superior image quality, making it an ideal choice for businesses catering to unique customer demands. By leveraging the advantages of DTF printing, companies can offer diverse fabric selections and maintain high production efficiency while ensuring durable and visually stunning outputs. As the market for personalized garments expands, mastering this DTF printing technology becomes increasingly vital for entrepreneurs looking to thrive in a competitive landscape.

Understanding DTF Printing: A Comprehensive Overview

Direct-to-Film (DTF) printing has rapidly become one of the go-to solutions for custom apparel across various industries. This innovative technology is not just a passing trend; it represents a significant evolution in how designs are transferred onto fabric. Unlike traditional methods, DTF printing allows for vibrant colors and intricate designs, resulting in high-quality outputs that are both visually appealing and durable.

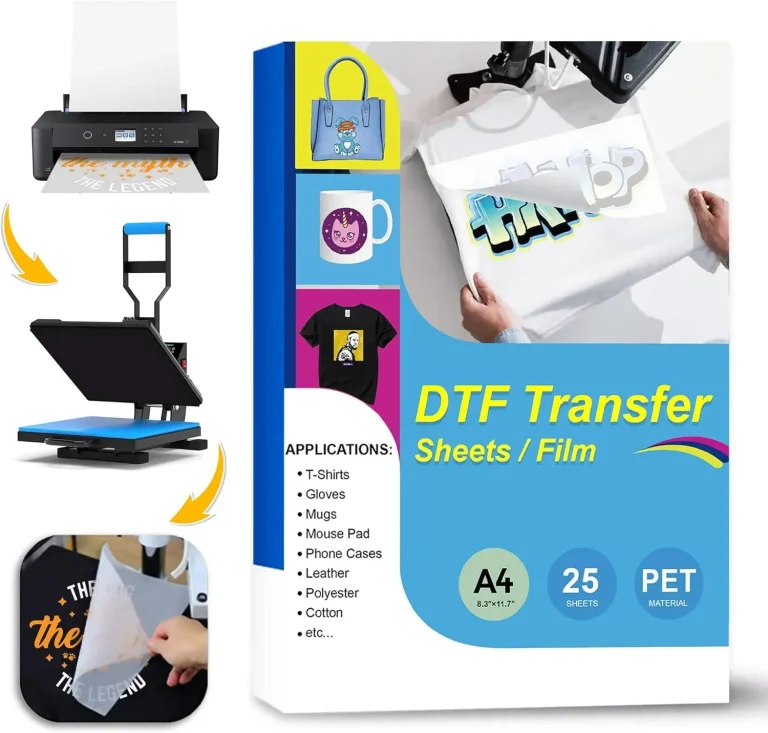

At its core, DTF printing involves several essential steps that include designing graphics using advanced software, printing these designs onto a special film, and finally transferring them to textiles using heat. This technology simplifies the printing process and reduces the time and resources needed to produce customized items, making it a valuable asset for businesses focusing on personalized apparel.

The DTF Printing Process: Step-by-Step Guide

The DTF printing process can be broken down into three significant stages that ensure precision and quality. The first step, ‘Printing on Film,’ involves using state-of-the-art printers to create high-resolution images on specialized films using long-lasting inks. This method guarantees that the images will appear vibrant and sharp once applied to fabric. The choice of ink is also crucial, as it determines the longevity and visual appeal of the final product.

In the second step, ‘Applying Adhesive,’ an essential adhesive powder is applied to the printed film, which is later activated using heat. This phase ensures that the ink adheres firmly to the fabric during the transfer process. Finally, in the last stage, ‘Heat Transfer to Fabrics,’ the heat press plays a pivotal role in transferring the design from the film to the garment. This meticulous process enables the creation of designs that not only look fantastic but also withstand multiple washes without fading or peeling.

Advantages of DTF Printing for Businesses

One of the standout advantages of DTF printing is its unparalleled flexibility, catering to a broad spectrum of fabrics and colors. For small businesses or startups that thrive on custom orders, this versatility allows for rapid turnaround times without sacrificing quality. Whether you are printing on cotton, polyester, or blends, DTF technology provides reliable results across various textile types.

Additionally, DTF printing is a cost-effective solution for low-volume productions. Traditional printing methods often entail high setup costs that can be prohibitive for smaller runs. In contrast, DTF allows businesses to create quality prints with minimal upfront investment, making it an attractive option for those looking to enter the apparel printing market.

Recent Innovations in DTF Printing Technology

The DTF printing landscape is continuously being reshaped by technological advancements that enhance efficiency and quality. The introduction of eco-friendly inks is one such development, enabling businesses to cater to environmentally conscious consumers. These water-based inks not only reduce the ecological footprint but also maintain the vibrant colors associated with DTF printing.

Moreover, the rise of automation in DTF printing processes, such as automated film changes and adhesive application, is allowing businesses to improve productivity and minimize human error. This shift towards automated solutions means that printing operations can become more streamlined, ultimately leading to quicker turnaround times and an enhanced ability to meet market demands.

Market Trends Impacting DTF Printing Growth

The growing consumer demand for personalized products has significantly boosted the DTF printing market. As more customers seek unique, custom apparel, DTF technology aligns perfectly with this need. It enables businesses to fulfill small-batch orders efficiently, making it easier for brands to cater to individual tastes while keeping production costs manageable.

Furthermore, the acceleration of e-commerce has transformed how businesses approach printing solutions. With the need for reliable and high-quality printing becoming paramount in online retail, DTF printing is poised to be a key player in ensuring that brands can provide customers with rapid, durable, and customized merchandise.

Exploring the Future Potential of DTF Printing

Looking ahead, the future of DTF printing holds great promise, particularly with ongoing technological advancements. Innovations in print head technology and improved ink formulations are likely to result in better resolution and color accuracy. This means that the aesthetic quality of DTF printed apparel could reach new heights, appealing to even the most discerning consumers.

Moreover, the versatility of DTF printing is expected to broaden its applications beyond just apparel. The potential to tap into markets for home textiles, promotional items, and accessories presents exciting opportunities for businesses willing to adopt this innovative printing technology.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a modern textile printing method that transfers designs from a special film to fabric. The process involves printing high-resolution images onto a PET film using quality inks, applying a heat-activated adhesive, and then using a heat press to transfer the image onto materials like cotton or polyester.

What are the advantages of DTF printing compared to other printing methods?

The advantages of DTF printing include its flexibility in printing on various fabric types, cost-effectiveness for small runs, superior quality and durability of prints, and quick production times. This method is particularly beneficial for businesses that prioritize customization and high-quality outputs.

Can DTF printing be used for custom apparel printing?

Yes, DTF printing is ideal for custom apparel printing as it allows for vibrant designs on a wide range of fabrics. This process supports small-batch productions, making it perfect for businesses that cater to personalized clothing needs.

How does the DTF printing process ensure print durability?

The DTF printing process guarantees print durability by utilizing high-quality inks and a heat-activated adhesive that bonds the design effectively to the fabric. This results in vibrant colors that resist fading and bleeding, ensuring they withstand multiple washes.

What advancements are being made in DTF printing technology?

Recent advancements in DTF printing technology include the development of eco-friendly, water-based inks and increased automation in the printing process. These innovations improve productivity, reduce environmental impact, and enhance print quality.

What trends are driving the growth of the DTF printing market?

Key trends driving DTF printing growth include an increasing demand for personalized clothing, the rise of e-commerce, and the global expansion of fashion. DTF printing meets the need for quick, quality custom printing, aligning with the market’s evolving demands.

| Key Points | Details |

|---|---|

| What is DTF Printing? | Direct-to-Film printing combines innovative techniques to transfer designs onto fabrics using specialized PET film and heat transfer. |

| Process Overview | 1. Printing on Film: High-resolution images are printed on special DTF films. 2. Applying Adhesive: Adhesive powder is applied and activated with heat. 3. Heat Transfer to Fabrics: Using a heat press, the design is transferred onto fabric ensuring durability. |

| Advantages of DTF Printing | – Flexibility in fabric and color. – Cost-effectiveness for small runs. – High quality and durability. – Quick production times. |

| Recent Developments | – Eco-friendly inks now available. – Automation in production increases efficiency and reduces errors. |

| Market Trends | – Growing demand for personalized clothing. – Increased e-commerce opportunities. – Global adoption of DTF technology. |

| Future Potential | – Anticipated improvements in print quality. – Expansion into new markets like home textiles and promotional products. |

Summary

DTF printing is swiftly becoming a vital process in the world of textile printing, offering remarkable flexibility and quality. Businesses can harness the potential of this innovative technology, which not only supports diverse fabric options but also meets the rising demand for personalized and quick turnaround products. With ecological advancements in print processes and a strong foothold in the e-commerce market, DTF printing stands to revolutionize how garments are created and delivered. As trends evolve, staying ahead in understanding DTF printing will ensure businesses can effectively cater to a dynamic consumer landscape.