DTF Printing: The Advantage Over Traditional Methods

DTF printing, or Direct-to-Film printing, is rapidly transforming the landscape of the printing industry as businesses seek innovative solutions to meet consumer demands. Unlike traditional printing methods, which often involve multiple layers and time-consuming setups, DTF printing offers a streamlined approach, allowing for vibrant designs to be applied directly onto various fabrics efficiently. With the DTF Gangsheet Builder, users can optimize their printing process, streamlining production while maintaining exceptional quality. This modern printing technology provides significant advantages over traditional techniques, including screen printing, by reducing costs and setup times for small batches. As printing technology evolves, understanding the benefits of DTF printing becomes essential for businesses aiming to stay competitive in a bustling market.

Exploring the realm of contemporary printing techniques opens discussions about Direct-to-Film printing, a method that is gaining traction among businesses seeking versatility and quality. Often compared to classic approaches like screen printing and heat transfer, this technology leverages the DTF Gangsheet Builder to produce dynamic, high-resolution designs on various textile materials. As companies contemplate shifts in their production strategies, understanding the distinctions between these printing modalities becomes crucial. Not only do these alternative terms encapsulate the essence of the process, but they also signal the innovative spirit driving the evolution of the printing industry. The rising popularity of direct-to-film technology highlights a shift towards efficient, cost-effective solutions that cater to a diverse range of consumer preferences.

The Evolution of DTF Printing Technology

DTF, or Direct-to-Film printing, represents a significant shift in the world of printing technology. Unlike traditional methods that require the creation of screens and complex setups, DTF printing simplifies this process by using specialized printers to transfer designs directly onto a film. This not only streamlines production but also opens the door for businesses to experiment with a broader range of designs and colors, catering to diverse customer demands. The technological advancements accompanying DTF printing, including the development of new ink formulations, further enhance print durability and flexibility.

As DTF technology continues to evolve, it incorporates more efficient printing systems and enhanced software integrations that ease the workflow from design to production. With the introduction of faster print speeds and improved materials, businesses can now handle larger orders without compromising quality. This evolution is crucial, as it allows companies to meet the fast-paced market demands while promoting sustainability by reducing waste and energy consumption associated with traditional printing methods.

Benefits of DTF Gangsheet Builder Technology

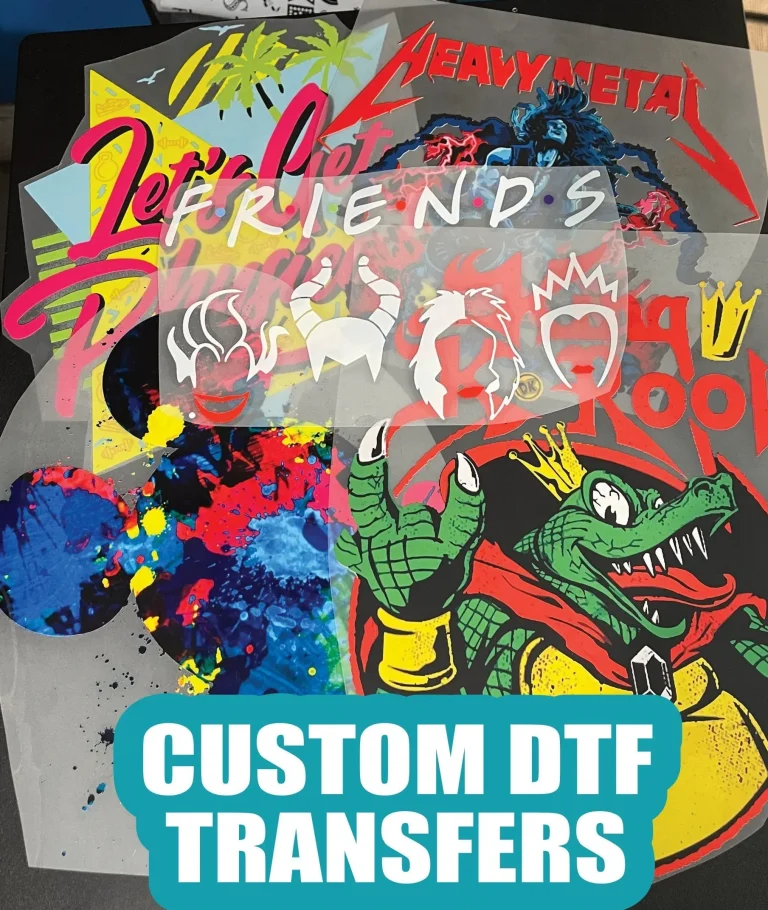

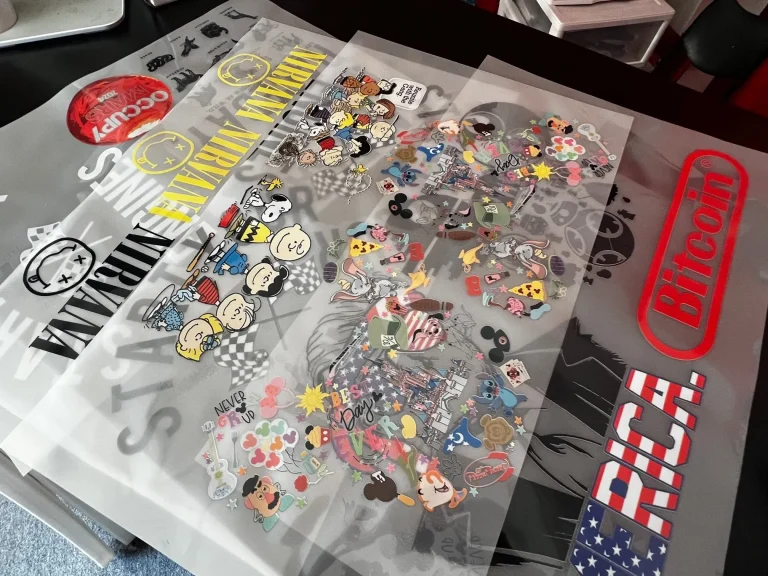

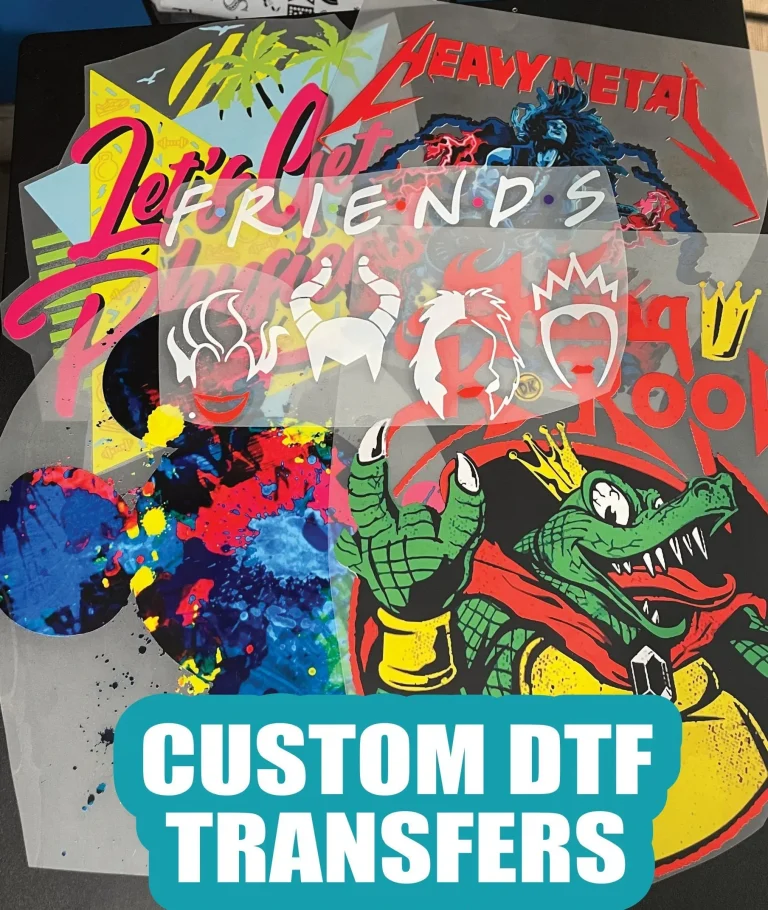

The DTF Gangsheet Builder is a revolutionary tool that allows businesses to print multiple designs on a single sheet. This method significantly optimizes material usage, reducing costs per unit compared to traditional screen printing setups. By leveraging this innovative approach, small apparel shops and start-ups can produce customized items in lower quantities without incurring hefty initial setup fees. Additionally, since DTF printing requires minimal physical resources, it becomes ideal for bespoke orders that require quick turnaround times.

Moreover, DTF Gangsheet Builder technology permits intricate and colorful designs that may be tricky to achieve with traditional techniques. The flexibility of DTF allows businesses to explore creative avenues previously limited by conventional printing. With easier adjustments and rapid iterations, businesses can respond immédiately to trends and consumer feedback, thus fostering an environment of creativity and adaptability.

Cost Comparison: DTF Printing vs. Traditional Methods

Cost-effectiveness is a vital factor when businesses decide between DTF printing and traditional methods like screen printing. DTF printing generally incurs lower setup costs due to the absence of complex preparations needed for screen printing, making it ideal for small to medium-sized orders. While traditional methods tend to offer lower prices for high-volume runs due to economies of scale, the initial investment required can deter smaller enterprises or those focused on custom prints.

Businesses must evaluate their order volume and production strategies to determine which method serves them best financially. For those who regularly fulfill small orders or require frequent design changes, DTF printing emerges as a more economical choice. Conversely, larger businesses looking to capitalize on volume discounts may still find traditional printing methods advantageous for maximizing long-term profitability.

Quality Assurance in DTF vs. Traditional Printing

Quality is paramount across all printing methods, and both DTF and traditional printing techniques offer unique strengths. DTF printing is particularly celebrated for its ability to produce bright, detailed images that rival the quality of screen printing. By utilizing a transfer film, designs can achieve a depth of color and clarity that appeals to modern consumers seeking high-quality graphics.

On the other hand, traditional methods, especially advanced screen printing techniques, can deliver exceptional durability and vibrancy. When using high-quality inks and proper curing processes, traditional prints can outlast their counterparts, especially for frequent wash and wear applications. Therefore, businesses must be deliberate in choosing the printing method that aligns with their quality standards and end-user expectations.

Durability Considerations in Printing Methods

Durability is a significant factor in the longevity of printed garments, particularly for items subject to frequent use and washing. DTF printing, when properly cured, exhibits impressive durability, maintaining vibrant colors and detailed designs over multiple wash cycles. This makes DTF an appealing choice for everyday apparel and fashion items that need to retain their original appearance.

However, traditional printing methods often claim higher durability when high-quality inks and materials are used in the process. Screen printing, especially, has a proven track record of producing prints that withstand the test of time, primarily due to their thicker ink layers. Therefore, businesses should assess their target market’s needs, weighing the durability aspects of DTF against traditional printing techniques to ensure customer satisfaction.

Future Trends in Printing Technology

The landscape of printing technology is ever-evolving, with new advancements poised to change how we approach various printing methods. DTF printing is gaining ground, showcasing greater versatility and innovation that appeals to modern businesses and consumers alike. As technology continues to improve, we can expect DTF to integrate advanced features that enhance user experience, including more intuitive software, faster printing speeds, and better ink formulations that broaden the range of materials on which designs can be printed.

Furthermore, emerging trends indicate a growing emphasis on sustainable practices within the printing industry, with DTF innovations often aligning with eco-friendly ideals. As businesses strive for responsible production methods, embracing DTF technology can position them as industry leaders committed to sustainability while still achieving outstanding print quality and performance.

Frequently Asked Questions

What is DTF printing and how does it differ from traditional printing methods?

DTF printing, or Direct-to-Film printing, is a modern printing technology that uses a specialized printer to print designs onto a film, which is then transferred onto fabric. Unlike traditional printing methods like screen printing, which require complex setups and physical screens, DTF printing provides quicker setup times, making it more cost-effective for short production runs.

How does the DTF Gangsheet Builder enhance the DTF printing process?

The DTF Gangsheet Builder allows users to optimize the arrangement of multiple designs on a single film, maximizing material usage and reducing costs. This feature is particularly beneficial for businesses looking to produce various designs simultaneously without the high setup costs associated with traditional methods.

What are the advantages of DTF printing compared to screen printing?

DTF printing offers several advantages over screen printing, including versatility in printing on various materials like cotton and polyester, quicker setup times, and the capability to produce high-quality designs with detailed gradients. This makes DTF printing ideal for small businesses and custom apparel shops that cater to diverse fabric types.

Is DTF printing more cost-effective for small orders compared to traditional printing methods?

Yes, DTF printing is generally more cost-effective for small order quantities due to its low setup costs and efficient use of materials. In contrast, traditional methods such as screen printing are better suited for larger volume orders where economies of scale can significantly reduce the production cost per unit.

How durable are DTF prints compared to traditional prints?

DTF prints can be highly durable when properly cured, enduring multiple washes without fading. However, some traditional printing methods, especially screen printing with high-grade inks, can produce even more durable prints. The choice of method will ultimately depend on the specific requirements of the garment and its intended use.

How is market adoption of DTF printing changing the landscape of printing technology?

The market adoption of DTF printing is rising rapidly, driven by smaller businesses and custom apparel shops seeking efficient and versatile printing solutions. As e-commerce and personalized merchandise grow, DTF printing technology is becoming a popular choice, thanks to its ability to produce vibrant designs quickly, catering to diverse consumer demands.

| Feature | DTF Printing | Traditional Methods |

|---|---|---|

| Cost-Effectiveness | More economical for small orders due to low setup costs. | Better for large volume orders due to economies of scale. |

| Quality | High-quality outputs with intricate designs and vibrant colors. | Can deliver exceptional quality but may struggle with fine details unless optimized. |

| Durability | Can endure multiple washes when correctly cured. | Potentially more durable when high-quality inks and materials are utilized. |

| Versatility | Prints on various materials like cotton, polyester, and blends. | Often limited to specific textile types based on the method. |

| Setup Time | Requires less setup time, suitable for short production runs. | Typically involves longer setup times, which can delay production. |

Summary

DTF printing is revolutionizing the textile industry, offering a fresh approach to garment decoration by making complex designs achievable with ease. This method stands out for its adaptability across various fabric types and for smaller production runs, making it a practical choice for many businesses. As e-commerce continues to grow, the advantages of DTF printing in terms of cost-effectiveness, quality, and durability will further solidify its place in the market. Understanding these benefits is essential for businesses aiming to stay competitive and meet modern consumer demands.