DTF Printing Revolutionizes Custom Designs for T-Shirts

DTF printing, or Direct to Film printing, is revolutionizing the world of custom T-shirt printing with its innovative technology that enhances design possibilities. Unlike traditional methods, DTF printing technology allows for vivid colors and intricate details, making it an attractive option for designers and brands alike. As an eco-friendly printing solution, this approach minimizes waste while maximizing quality, catering to the growing demand for sustainable fashion. This article will dive into the remarkable benefits of DTF printing, exploring not only its efficiency in producing stunning apparel but also its versatility across various fabrics. Join us as we uncover how DTF is reshaping T-shirt printing methods for the better, paving the way for a more vibrant and sustainable future in custom designs.

Also known as Direct to Film printing, this modern printing technique is setting new standards in the custom apparel industry. Its ability to produce detailed and colorful prints on an array of garments has made it a favorite among creators looking to make a statement. Additionally, this printing approach champions eco-friendly practices, aligning with consumer demands for responsible production methods. As we delve deeper into the capabilities of DTF printing, we will highlight the many advantages it offers over traditional T-shirt printing methods. From enhanced print quality to efficient short-run production, this innovative process is truly changing the dynamics of how we create and wear custom apparel.

The Benefits of DTF Printing for Custom Apparel

DTF printing offers a plethora of benefits for those seeking to create custom apparel, particularly when it comes to T-shirt printing. One of the most significant advantages is the ability to achieve vivid colors and extraordinary detail in designs. This method employs high-resolution digital processes, allowing for sharp images and vibrant hues that can elevate any garment. Unlike traditional screen printing, which may restrict the complexity of designs due to setup costs and limitations in color variety, DTF printing empowers designers to unleash their creativity with virtually limitless color options.

Moreover, DTF printing’s adaptability on various fabrics cannot be overstated. Whether the garment is made from cotton, polyester, or a blend, this technology can print solidly without compromising the fabric’s integrity. This versatility opens up a new realm of possibilities for apparel designers, making it easier to produce unique and customized T-shirts that cater to diverse audiences. As a result, both established fashion brands and emerging creators are swiftly adopting DTF printing to differentiate their offerings and meet specific consumer demands.

Eco-Friendly Aspects of DTF Printing

In an era where environmental consciousness is at an all-time high, eco-friendly printing solutions like DTF printing are gaining immense popularity. This technique primarily uses water-based inks, which are significantly less harmful than the solvent-based inks common in traditional printing processes. The low environmental impact associated with DTF printing not only enhances the appeal of the final product but also aligns with the values of eco-conscious consumers, thus making it a smart choice for brands looking to promote sustainability.

Additionally, DTF printing reduces waste as it allows for on-demand printing of individual designs or small batches. This mitigates the need for large-scale production runs, which often result in surplus inventory. As businesses increasingly aim to minimize their carbon footprint and promote sustainable practices, DTF printing emerges as a solution that supports both aesthetic appeal and ethical responsibility in the fashion industry. The move towards greener practices indicates a vital shift in consumer expectations, making DTF a valuable asset for forward-thinking brands.

Cost-Effectiveness of DTF Printing

Cost-effectiveness is another area where DTF printing excels, particularly for small businesses or individual designers. Traditional T-shirt printing methods, like screen printing, involve considerable setup costs that can be prohibitive for low-volume orders. In contrast, DTF printing reduces these initial expenses, making it economically feasible for businesses to produce short runs of customized designs without incurring prohibitive costs. This accessibility allows more creators to enter the market and cater to niche audiences without substantial financial risk.

In addition, DTF printing eliminates the need for large minimum order quantities, empowering designers to create unique pieces based on current trends or customer demands. This flexibility encourages a more dynamic approach to T-shirt design, where trends can be swiftly adapted to meet consumer interests. By lowering barriers to entry and fostering creativity, DTF printing facilitates a vibrant market for custom apparel that thrives on innovation and individuality.

Recent Trends in DTF Printing

The DTF printing market is currently experiencing significant growth, fueled by rising consumer demand for personalized apparel. As more businesses recognize the value of offering custom designs, DTF technology is being rapidly adopted to fulfill this need. Reports indicate a steady increase in market acceptance, with advancements in technology enabling companies to perform quicker, more efficient production without sacrificing quality. This trend signals a promising future for DTF as a leading method in the custom apparel industry.

Moreover, technological innovations are consistently enhancing the DTF printing process. Newer models of printers are designed to improve speed, print resolution, and user-friendliness, ensuring that businesses can meet increasing demands without compromising on quality or efficiency. These advancements are expected to further drive growth in the DTF printing market, as they offer both experienced businesses and newcomers the capability to produce high-quality, custom T-shirt designs quickly and effectively.

Educational Resources for DTF Printing Techniques

As DTF printing gains traction, the resources available for learning about this technology are broadening. Numerous online platforms, including forums, tutorials, and workshops, are emerging to support both novice and experienced users in mastering DTF techniques. These educational resources not only enhance practical skills but also foster a community atmosphere where creative professionals can share their insights and collaborate on projects, ultimately enriching the industry as a whole.

Additionally, communities focused on DTF printing have sprung up across social media and professional networks. These platforms allow users to exchange tips, troubleshoot issues, and showcase their work. As the popularity of DTF printing continues to grow, the shared knowledge among these communities becomes invaluable, empowering individuals to innovate further and improve their custom designs, ultimately contributing to the advancement of the apparel industry.

The Future of Custom T-shirt Printing with DTF Technology

The future of custom T-shirt printing appears increasingly intertwined with DTF technology as it continues to gain ground over traditional methods. Analysts predict that DTF printing will increasingly dominate the market due to its numerous advantages, including high-quality output, sustainability, and adaptability to various fabrics. As consumers continue to seek unique expressive designs in their apparel, DTF printing will likely emerge as the go-to solution for brands aiming to meet these evolving demands.

Furthermore, ongoing technological advancements suggest that DTF printing will become even more efficient and accessible. As the industry embraces digital transformation, innovations such as automatic pre-treatment and more advanced printers will streamline production processes, enabling designers to create and deliver products faster than ever. This trend not only boosts efficiency but also encourages more creative experimentation in custom T-shirt designs, ensuring that DTF printing remains at the forefront of the apparel industry.

Frequently Asked Questions

What is DTF printing and how does it work for custom T-shirt printing?

DTF printing, or Direct to Film printing, is a modern technology used in custom T-shirt printing that involves printing designs onto a special film with high-resolution digital printers. The ink is then transferred to the garment using heat and pressure, ensuring vibrant colors and intricate details.

What are the eco-friendly benefits of DTF printing?

DTF printing offers eco-friendly printing solutions by utilizing water-based inks, which significantly reduce harmful emissions when compared to solvent-based inks used in traditional printing methods. This makes DTF printing a sustainable choice for businesses that are conscious of their environmental impact.

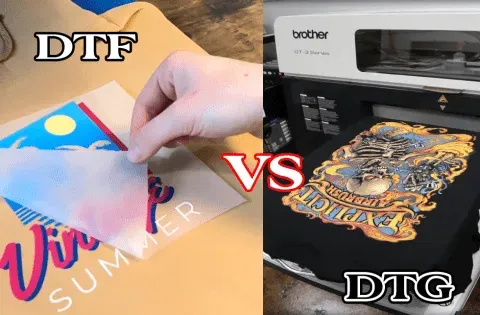

How does DTF printing compare to other T-shirt printing methods?

When compared to other T-shirt printing methods like screen printing or sublimation, DTF printing stands out for its versatility on various fabrics, sharp color reproduction, and cost-effectiveness for short runs. This technology can easily adapt to cotton, polyester, and blends, catering to diverse design needs.

What are the key benefits of Direct to Film printing?

Direct to Film printing benefits include exceptional print quality with vibrant colors, the ability to print on various fabric types without restrictions, lower setup costs for small runs, and reduced environmental impact due to the use of water-based inks, making it the preferred choice for custom apparel.

Is DTF printing suitable for small businesses and individual creators?

Yes, DTF printing is particularly suitable for small businesses and individual creators because it eliminates high setup costs typically associated with traditional printing methods. This allows custom designs to be produced economically, making it accessible for personalized items and smaller orders.

What recent trends are influencing the growth of DTF printing technology?

Recent trends influencing DTF printing technology include significant market growth driven by increased demand for personalized apparel, technological advancements that improve printing speed and quality, and the emergence of educational resources and communities that support users in mastering DTF printing techniques.

| Key Points | Description |

|---|---|

| Focus Keyword | DTF Printing – Direct to Film printing is fundamentally reshaping custom apparel, especially T-shirt designs. |

| Advantages | 1. Vibrant Colors and Detail: Produces sharp, detailed, and colorful designs that outshine traditional methods. 2. Versatility: Works on various fabrics, enhancing creative potential. 3. Sustainable Practices: Utilizes water-based inks, minimizing environmental impact. 4. Cost-Effectiveness: Ideal for short runs, allowing personalized and small batch production without heavy setup costs. |

| Recent Trends | 1. Market Growth: Anticipated significant growth in the U.S. DTF printing market, driven by demand for personalized apparel. 2. Technological Advancements: New printers enhancing speed, efficiency, and print quality. 3. Educational Resources: Growing communities and resources available for users to master DTF technologies. |

Summary

DTF Printing is revolutionizing the apparel industry by providing innovative and sustainable solutions for custom designs. This advanced printing technique not only excels in delivering vibrant colors and intricate details but also offers unmatched versatility across various fabrics. With its eco-friendly inks and cost-effective approach for small runs, DTF printing is an invaluable asset for both brands and individual creators. As the demand for personalized apparel continues to rise, the future of DTF printing looks promising, making it a pivotal player in transforming how we approach custom T-shirt and apparel manufacturing.