DTF Printing: Essential Supplies for Success

DTF printing, or Direct-to-Film printing, is revolutionizing the world of textile printing with its incredible ability to produce high-quality, customizable designs with ease. As businesses and creatives alike seek to create unique apparel, understanding the essential DTF printing supplies becomes paramount. From specialized DTF printers and vibrant DTF inks to high-performance DTF transfer films and efficient heat press machines, each component plays a crucial role in the overall printing process. This innovative technology not only ensures impressive color reproduction but also durability and washability of the final product. In this article, we will delve into the necessary steps and tools that unlock the full potential of DTF printing.

The world of textile printing is rapidly evolving, and among the latest advancements is the technique commonly referred to as film-based transfer printing. This process involves printing graphics onto a specialized film that can then be applied to various fabrics through heat application. It has become increasingly popular due to its ability to deliver extraordinary vibrancy and detail, making it a favored method for custom apparel production. Whether you refer to it as film transfer printing or DTF technology, grasping the essentials of the procedure—including the best printers, inks, and application methods—is key to achieving professional results.

Understanding the Fundamentals of DTF Printing

Direct-to-Film (DTF) printing is a printing technique that leverages special transfer films to achieve high-quality and vibrant prints on textiles. This method has gained popularity due to its flexibility, allowing users to create detailed designs without considerable setup costs, making it ideal for small businesses and independent artists. Unlike traditional printing methods, DTF printing transfers images directly through a heat press, ensuring excellent adhesion and durability of the prints.

One of the standout features of DTF printing is its ability to produce designs that maintain their clarity and vibrancy even after multiple washes. The printing process involves directly applying high-resolution inks onto a transfer film specifically coated to bond effectively with fabric. This results in a soft, smooth feel that doesn’t crack or peel, which is a common issue with other printing techniques. Understanding these fundamentals can set the stage for a successful DTF printing venture.

Essential DTF Printing Supplies for Success

To ensure success in DTF printing, having the right supplies is paramount. The most crucial item is a high-quality DTF printer. Models like the Epson L1800 are specifically designed for this purpose and can produce sharp, vibrant images that are essential for professional-grade apparel. Additionally, selecting premium DTF inks plays a critical role in the printing process. These water-based inks are formulated to adhere properly to both the transfer films and fabrics, resulting in ideal prints that pop with color and detail.

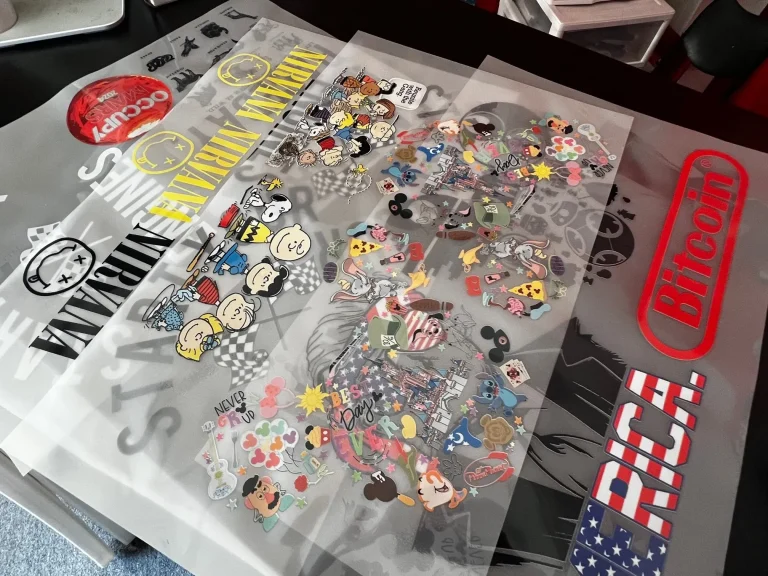

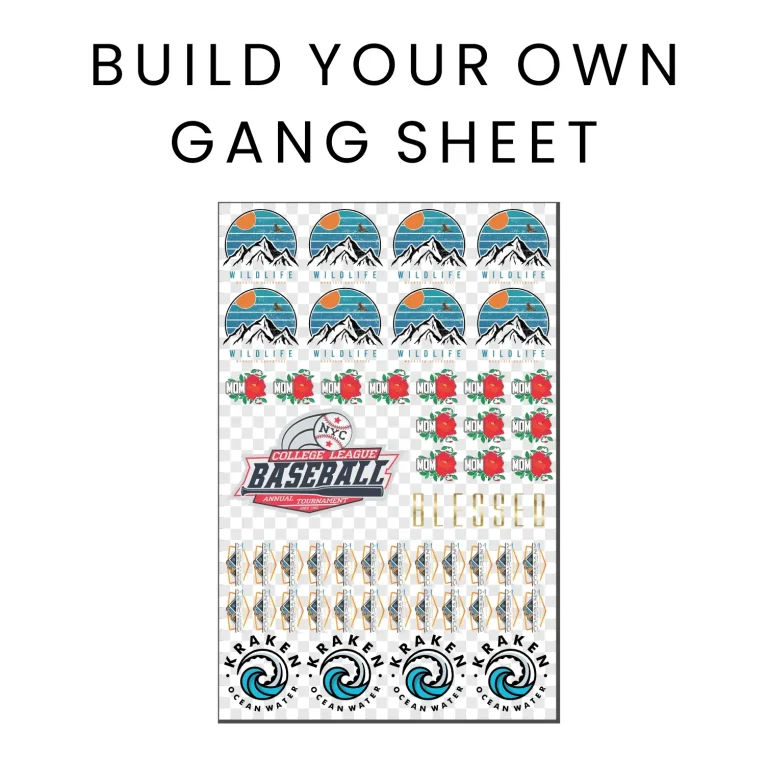

Moreover, transfer films come in different finishes, such as matte and glossy, allowing for creative flexibility based on the desired end product. The choice of transfer film should correspond to the type of ink being used to ensure optimal bonding. Coupled with appropriate DTF powders and a reliable heat press, each supply contributes to the overall quality and durability of the printed designs, highlighting the importance of selecting high-grade materials.

Choosing the Right DTF Printer for Your Needs

When it comes to DTF printing, selecting the appropriate printer can make all the difference in the quality of your output. A dedicated DTF printer has been optimized for consistent ink distribution and high-resolution printing, which is essential for detailed artwork. Popular choices in the market include the Epson SureColor series, which can be adapted for DTF use, offering vast potential for creative projects. Investing in a high-quality printer limits the chances of technical issues, fostering a smooth printing process.

It’s also important to research and consider factors such as printing speed, compatibility with different media types, and manufacturer support. A printer that is adaptable to various printing settings will provide a versatile foundation for your custom printing business. Ultimately, a solid investment in a reliable DTF printer contributes significantly to producing remarkable prints that satisfy customer expectations.

The Importance of DTF Inks for High-Quality Prints

DTF inks are crucial in defining the overall outcome of the printing process. These inks are specially formulated to be water-based, ensuring a brilliant color output while maintaining excellent adhesion to the transfer film. Many brands have introduced their unique formulations that cater specifically to diverse fabric types and desired finishes, making it essential to choose high-grade inks that have a proven track record within the DTF community.

Quality DTF inks not only provide vibrant colors but also contribute to the longevity of the designs. They must withstand the rigors of washing and wearing, ensuring that the prints hold up over time. By opting for reputable ink brands, you enhance the probability of producing eye-catching products that can meet customer demands, thereby establishing a reliable reputation for your custom printing business.

Selecting the Best Transfer Films for DTF Printing

Choosing the right transfer film is paramount in the DTF printing process, as it affects the final appearance and durability of the prints. DTF transfer films come in various textures, including matte and glossy finishes, which can transform the look of any design. The selection should align with the type of DTF inks being utilized, as compatibility greatly enhances the adherence and overall effectiveness of the transfer.

Additionally, high-quality transfer films have a coating that facilitates the bonding of ink to both the film and the fabric. This aspect is vital for achieving crisp, vibrant prints that withstand washing and maintaining their integrity over time. Therefore, investing in excellent transfer films not only impacts the visual appeal but also significantly elevates the performance of the finished product.

Understanding the Role of Heat Press in DTF Printing

A heat press is one of the most vital tools in DTF printing, as it ensures the successful transfer of designs from the film to the fabric. The correct temperature and pressure settings are critical in achieving an optimal bond between the ink and material. Various models are available in the market, but clamshell-style heat presses are popular due to their ease of use and efficiency in transferring designs.

Utilizing a reliable heat press can significantly impact the quality of the final product. Proper calibration guarantees that each transfer quality is consistent and reduces the likelihood of misprints. This reliability allows businesses to operate efficiently, producing high-quality apparel that satisfies customer expectations—essential in a competitive market.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a modern printing method that involves printing designs onto a specialized transfer film, which is then heat-pressed onto fabrics. This technique allows for high-resolution images and vibrant colors, ensuring durability and washability in custom apparel.

What types of DTF printing supplies do I need for best results?

For successful DTF printing, you need essential supplies including a high-quality DTF printer, premium DTF inks, transfer films, powder adhesive, and a reliable heat press. Each item plays a crucial role in achieving vibrant prints that adhere well to fabrics.

Can I use any printer for DTF printing?

While you can technically use some inkjet printers for DTF printing, it is recommended to use dedicated DTF printers or those specifically modified for this purpose, like certain Epson models. These printers ensure precise ink application and high-quality output, which are vital for successful prints.

How do I choose the right DTF inks for my printing projects?

Selecting high-grade, water-based DTF inks is crucial for printing vibrantly. Look for inks specifically designed for transfer films that guarantee excellent adhesion, color brightness, and soft feel on fabric. Established brands in the DTF community often offer the best options.

What is the role of heat press in DTF printing?

The heat press is an essential component in DTF printing, used to transfer designs from the transfer film to the fabric. An effective heat press should have adjustable temperature and pressure settings, allowing you to customize the process for different materials and achieving optimal adhesion.

Are there special considerations for DTF transfer films?

Yes, choosing the right DTF transfer film is critical for successful prints. DTF films come in matte or glossy finishes, and it’s important to select films compatible with your chosen DTF inks. A quality transfer film will ensure strong ink-to-fabric adhesion even after multiple washes.

| Key Supplies for DTF Printing | |

|---|---|

| High-Quality DTF Printer | Essential for precise ink placement. Recommended models include Epson L1800 and certain Epson SureColor series models. |

| Premium DTF Inks | Use high-grade, water-based inks for vibrant colors and excellent adhesion. |

| Transfer Films | Available in matte and glossy finishes; ensure compatibility with ink types. |

| Powder Adhesive | Applies to transfer film to enhance ink adherence to fabric. |

| Heat Press | Ensures proper temperature and pressure for transferring designs. |

| Post-Processing Supplies | Includes scissors, cutters, and cleaning tools to keep workspace organized. |

Summary

DTF printing represents a transformative approach for businesses looking to delve into custom apparel. With the right tools—such as high-quality DTF printers, premium inks, specialized transfer films, adhesive powders, and efficient heat presses—anyone can produce durable and vibrant prints. As the demand for personalized products continues to rise, understanding the essentials of DTF printing ensures that you are equipped to meet market needs effectively. The future of custom textiles is bright, and embracing DTF technology can unlock endless creative possibilities.