DTF Printing Demystified: Essential Insights for Beginners

DTF printing, or Direct-to-Film printing, is revolutionizing the landscape of custom apparel printing with its innovative approach to transferring designs onto fabrics. This cutting-edge DTF printing technology not only offers vibrant colors and intricate details but also fosters a sustainable printing solution for eco-conscious consumers and businesses alike. As the demand for personalized products surges, the versatility of DTF printing allows for a wide variety of materials, making it an ideal choice for both small enterprises and DIY enthusiasts. With fewer setup requirements compared to traditional methods, DTF printing empowers creators to realize their designs effortlessly. Join us as we delve into the essentials of DTF printing and explore how it’s reshaping the future of the textile industry.

Also known as Direct-to-Film technology, the DTF printing process stands out within the realm of custom garment decoration. This advanced technique involves the application of ink on a specialized film, which is then heat transferred onto fabrics, yielding high-quality, enduring results. As more individuals and businesses embrace the concept of personalized printing, alternative methods like DIY DTF are becoming increasingly popular among creators seeking to produce unique apparel without intricate setups. The growing emphasis on sustainable printing practices further emphasizes DTF’s appeal, as it minimizes waste and integrates environmentally friendly materials into the production cycle. Discovering the advantages and innovations associated with Direct-to-Film printing not only aids businesses in staying competitive but also encourages a more conscious approach to fashion and merchandise.

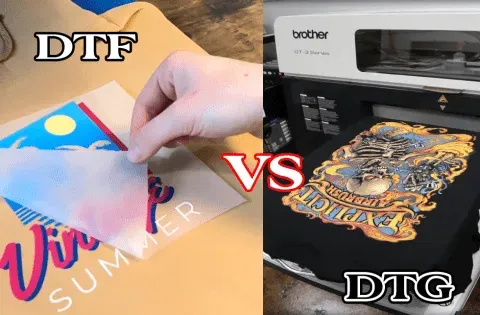

What Makes DTF Printing Stand Out in Custom Apparel?

DTF printing, with its unique method of applying designs onto textiles, has carved a niche in the custom apparel market. Unlike other printing techniques, such as screen printing or direct-to-garment (DTG) printing, DTF allows for sharper details and more vibrant colors, making it an appealing choice for designers and businesses alike. The process involves printing designs onto a specialized film that is heat-pressed onto the fabric, resulting in high-quality prints that can adhere to various materials—from cotton to polyester blends. This versatility not only broadens the scope of potential applications but also enhances the visual impact of custom apparel offerings.

Moreover, the efficiency of DTF printing is unparalleled. Traditional methods often require extensive setup, with multiple screens for different colors; DTF printing simplifies this by allowing multiple colors to be printed in one go. This streamlined approach significantly reduces production time and costs, making it an economically viable solution for small businesses looking to launch their custom apparel lines. As the demand continues to grow for personalized merchandise, DTF printing stands out as a game-changer in fulfilling these needs effectively.

The Technological Edge of DTF Printing

Recent advancements in DTF printing technology have propelled its popularity, making it more accessible and user-friendly. Modern DTF printers are equipped with advanced features that enhance print quality, reduce waste, and improve overall efficiency. Innovations in ink formulations have resulted in inks that better adhere to fabrics, ensuring durability while maintaining vivid colors. Furthermore, the development of new adhesive powders has made prints more resilient, allowing them to withstand repeated washes without fading or cracking. These technological improvements not only improve the end product but also help reduce operational costs for businesses.

Additionally, as manufacturers invest in research and development, the future of DTF printing is looking increasingly promising. Emerging technologies, such as eco-friendly inks and sustainable printing practices, are becoming more prevalent. As consumers become more eco-conscious, businesses incorporating these sustainable technology solutions into their DTF printing operations can appeal to a broader audience while contributing to the reduction of environmental impact within the apparel industry.

Sustainability Considerations in DTF Printing

As with any printing technology, sustainability is a critical topic in DTF printing. Although this method is generally more sustainable compared to traditional printing techniques—thanks to less material waste and lower energy consumption—there are still concerns regarding the environmental impact of certain inks and adhesives used in the process. The current trend toward eco-friendliness has prompted many DTF printers to seek out more sustainable materials, thus reducing their carbon footprint and appealing to environmentally-conscious consumers.

Companies are exploring various avenues such as water-based inks, which are less harmful to the environment, as well as biodegradable adhesives that align with sustainability goals. By prioritizing eco-friendly practices, the DTF printing industry can address ongoing environmental issues while also meeting the demands of a market that is increasingly favoring sustainable products. This focus on sustainability not only helps in building brand reputation but also contributes positively to the global movement towards greener manufacturing solutions.

The DIY DTF Printing Revolution

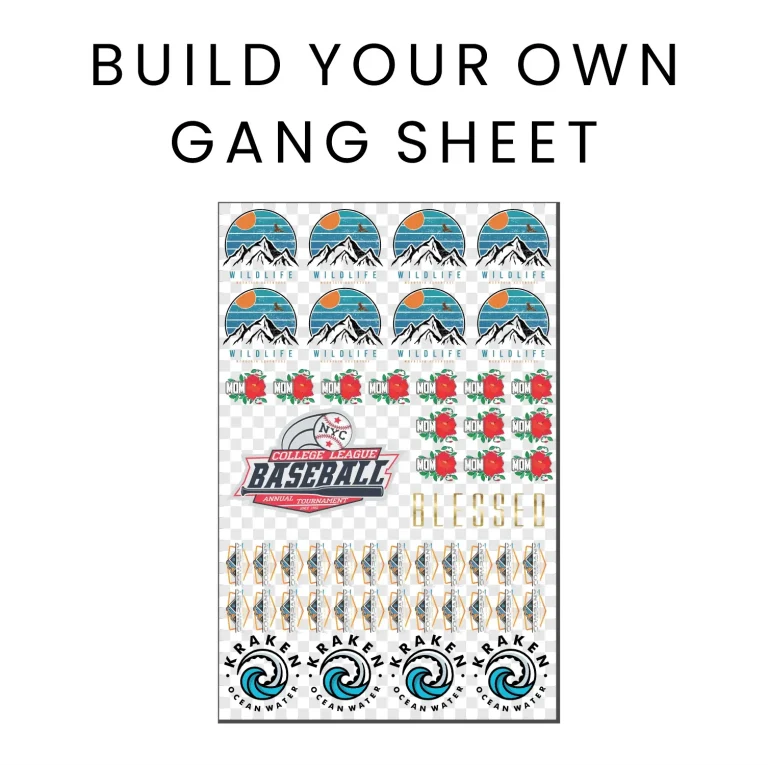

The emergence of the DIY DTF printing movement has transformed the landscape of custom apparel production, making it possible for entrepreneurs and hobbyists to engage directly with the printing process. With the availability of affordable equipment and materials, individuals can set up their own DTF printers and heat presses with relative ease. This accessibility encourages creativity and innovation, allowing users to create unique designs while sidestepping the barriers of traditional printing setups.

Furthermore, the DIY approach offers a learning opportunity for newcomers to the printing industry, providing them with hands-on experience in design and production. Enthusiasts can experiment with different techniques and materials, sharing insights and tips within their communities. This collaborative spirit fosters a vibrant ecosystem where ideas flourish and trends emerge, thereby enriching the overall custom printing market and paving the way for future advancements in DTF technology.

Exploring the Market Growth of DTF Printing

The DTF printing market is experiencing remarkable growth, positioned to capture a significant share of the global custom apparel market in the upcoming years. Factors contributing to this upward trend include the rising consumer demand for personalized clothing and the increasing popularity of unique design offerings. Research indicates that the DTF printing market could reach a value of USD 4 billion by 2025, reflecting the growing interest in tailored merchandise across various demographics.

This surge in popularity is particularly evident in regions like North America and Europe, where businesses are increasingly investing in DTF printing capabilities to differentiate themselves in a competitive market. As entrepreneurs and small businesses leverage DTF’s flexibility and efficiency, the implications for future growth are promising. Moreover, established brands are recognizing the potential of DTF printing to enhance their merchandise ranges, further driving expansion in this dynamic industry.

Future Innovations in DTF Printing Technology

Peering into the future of DTF printing technology reveals exciting advancements on the horizon. As competition in the custom printing space heats up, manufacturers are prioritizing research to innovate and improve existing DTF systems. Innovations such as advanced pre-treatments and cutting-edge printheads are key areas of development aimed at enhancing print quality, speed, and overall operational efficiency.

Additionally, the integration of artificial intelligence and automated processes within DTF printing operations is anticipated to revolutionize how businesses manage production and quality control. These technologies promise to reduce human error and streamline workflows, making it easier for companies to scale their operations without sacrificing quality. As these advancements unfold, the DTF printing industry is poised for transformative growth that aligns with future market demands, ensuring its relevance in the ever-evolving custom apparel landscape.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, also known as Direct-to-Film printing, involves printing designs directly onto a specially coated film, which is then transferred onto fabric using heat and pressure. This method allows for vibrant colors and fine details to be printed on various materials, making it an ideal choice for custom apparel.

What are the key benefits of using DTF printing for custom apparel?

The primary benefits of DTF printing include its versatility, cost-effectiveness, and ability to produce high-quality images on a wide range of fabrics. This technology eliminates the need for multiple screens like in traditional screen printing, making it easier for small businesses to create custom apparel efficiently.

How does DTF printing compare to traditional screen printing in terms of sustainability?

DTF printing is often regarded as more sustainable than traditional screen printing due to lower waste and energy consumption. However, some inks and adhesives used in the DTF process raise environmental concerns. The industry is actively working towards more eco-friendly materials and practices.

What advancements are being made in DTF printing technology?

Recent advancements in DTF printing technology include better printer capabilities and improved ink formulations. These innovations enhance print quality and durability, with new adhesive powders allowing for longer-lasting and more vibrant results on custom garments.

Can I start my own DIY DTF printing business?

Yes, the DIY DTF printing movement is growing, allowing individuals to set up their own printing operations using modified printers and heat presses. This trend provides an accessible way for hobbyists and entrepreneurs to explore custom apparel printing without the complexities of traditional methods.

What is the future outlook for the DTF printing market?

The DTF printing market is projected to grow significantly, with estimates reaching a global value of USD 4 billion by 2025. This growth is driven by rising demand for personalized merchandise, indicating a crucial role for DTF printing in the custom apparel sector.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A method printing designs onto a film for transfer to various textiles, offering vibrant colors and detail without needing multiple screens. |

| The Rise of DTF Printing | Increasingly popular among small businesses for its efficiency and quality, significantly changing the custom apparel landscape. |

| Versatility and Cost-Effectiveness | Allows easy production of high-quality designs on various fabrics, making it ideal for custom garments and promotional items. |

| Technological Advancements | Recent innovations have improved printer quality, ink formulations, and adhesive durability, enhancing overall print output. |

| Sustainability in DTF Printing | While more eco-friendly than some traditional methods, there are concerns with certain inks and adhesives; the sector is pushing for greener solutions. |

| Understanding the Market Landscape | Projected growth of the DTF printing market to USD 4 billion by 2025, driven by demand for personalized apparel and products. |

| Embracing the DIY DTF Movement | Entrepreneurs and hobbyists are creating their own setups, promoting creativity and engagement in custom printing. |

Summary

DTF printing is revolutionizing the custom apparel landscape through its innovative approach to fabric printing. By utilizing direct-to-film technology, this method allows for high-quality, vibrant designs that cater to the growing demand for personalized merchandise. As the DTF printing market expands, fueled by technological advancements and a surge in demand, it promises to shape the future of custom apparel production. Understanding its benefits, including versatility, efficiency, and sustainability, provides valuable insights for both industry professionals and consumers looking for eco-conscious, custom options in their fashion choices.