DTF Gangsheets: Tips and Tricks for Efficient Production

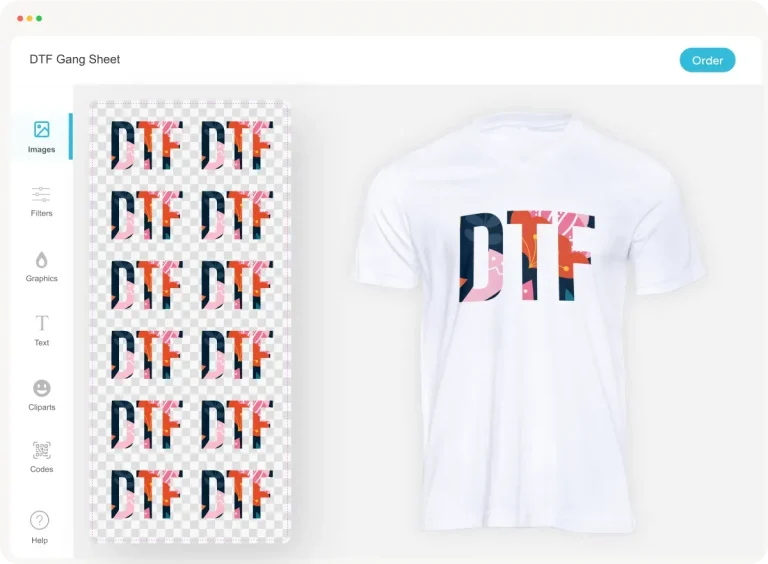

In the realm of garment decoration, **DTF gangsheets** have revolutionized the Direct to Film (DTF) printing process, allowing artists and businesses to unleash their creativity while optimizing efficiency. This innovative printing technique lets you combine multiple designs on a single film sheet, ultimately saving time and resources. With the right DTF printing tips, printers can streamline their workflow and boost production output significantly. By adopting advanced practices such as DTF design optimization, you’ll not only meet diverse customer needs but also enhance the overall quality of your prints. Let’s explore the fascinating world of DTF gangsheets and discover how they can elevate your printing endeavors.

DTF gangsheets, or multi-design print sheets, represent a cutting-edge approach in the clothing decoration industry, particularly within the domain of Direct to Film printing. This method empowers users to print several graphics on one single sheet of film, thereby minimizing waste and maximizing printing efficiency. By leveraging effective DTF printing strategies, such as optimizing designs and utilizing high-quality materials, businesses can streamline their production while achieving stunning results. Whether you’re a seasoned printer or just starting, understanding the nuances of these efficient production tools will be key to standing out in a competitive market. Let’s dive deeper into how DTF gangsheets can transform your printing capabilities and set your work apart.

Understanding Direct to Film Printing Techniques

Direct to Film (DTF) printing techniques have revolutionized the garment industry, providing a versatile approach to fabric decoration that appeals to both small businesses and large-scale operations. This innovative method employs a specialized film that allows vibrant images to be transferred onto multiple fabric types. By mastering DTF techniques, businesses can achieve high-quality prints with minimal waste, making DTF not just a choice, but a strategic decision in high-efficiency production.

The power of DTF printing lies in its ability to work across various substrates, from cotton to polyester and blends. This versatility opens avenues for creative design applications, enabling businesses to cater to diverse consumer demands. Understanding the nuances of DTF printing techniques, including ink selection and film thickness, will set companies apart in a competitive marketplace.

The Role of DTF Gangsheets in Efficient Production

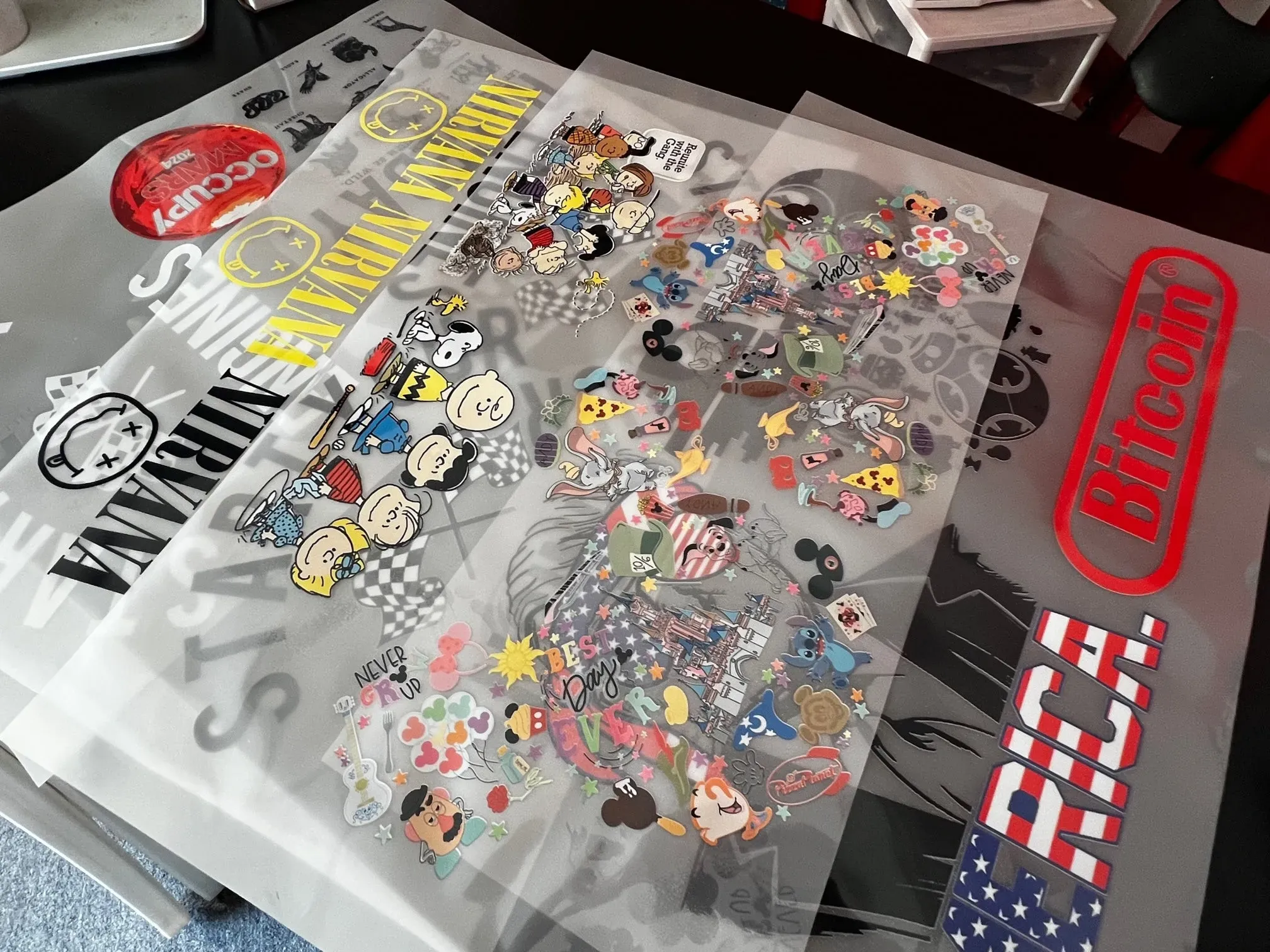

DTF gangsheets have emerged as a pivotal component in enhancing production efficiency. By allowing multiple designs to be printed simultaneously on a single sheet, gangsheets dramatically reduce setup time and resource expenditure. This not only conserves valuable materials but also increases output significantly, enabling businesses to meet higher order demands without compromising quality.

Leveraging DTF gangsheets is particularly advantageous for companies focused on optimizing production workflows. By strategically arranging designs and minimizing waste, businesses can cultivate a more sustainable production cycle. The benefits of this practice extend beyond mere cost savings; they also empower brands to innovate and experiment with a greater variety of designs, thereby enriching their overall product offerings.

Optimizing Designs for DTF Printing

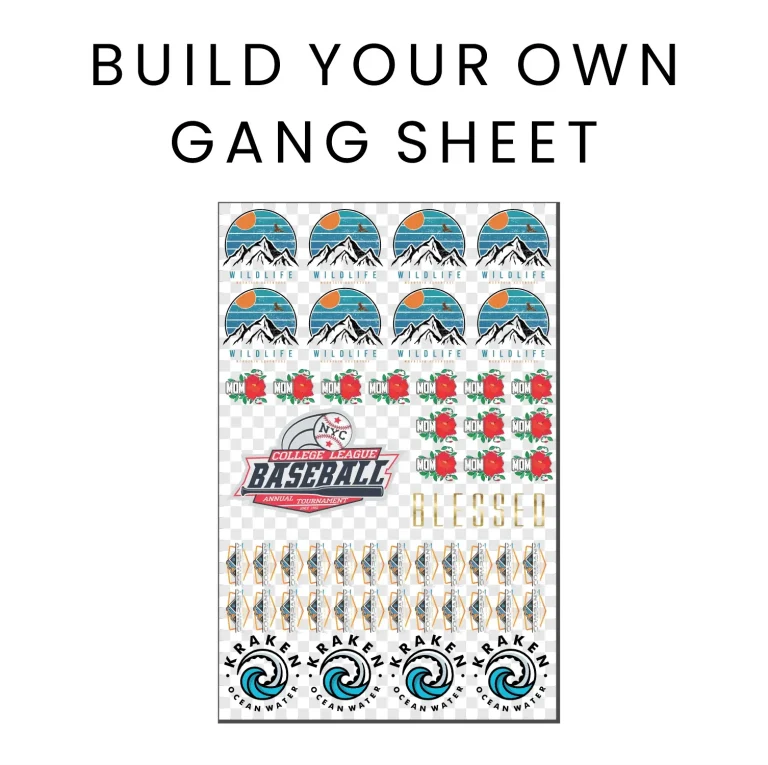

To fully capitalize on the efficiencies offered by DTF printing, optimizing designs is essential. Effective space management on the film can maximize print area usage, ensuring that every inch is utilized without gaps or overlaps. This attention to detail can significantly lower production costs and increase the number of designs printed per sheet.

Furthermore, maintaining the right design dimensions is crucial. While it’s important to create eye-catching graphics that resonate with audiences, they must also be appropriately scaled to fit on the gangsheets without distortion. This balance between creativity and practicality creates an optimal foundation for successful DTF printing.

Selecting Quality Materials for DTF Printing

The quality of ink and film used in DTF printing cannot be overstated. Selecting high-quality DTF inks is imperative for achieving vibrant colors and durability in finished products. These inks are designed to adhere effectively to various fabrics, resulting in prints that withstand washing and wear over time.

Equally important is the choice of film. Different fabrics may require specific film thicknesses to ensure optimal adhesion. By understanding the relationship between fabric types and film characteristics, printers can ensure that their final products exhibit excellent quality and longevity, benefiting both their reputation and customer satisfaction.

Mastering DTF Printing Techniques for Better Results

Mastering printing techniques is vital for achieving superior results in DTF printing. Layering techniques can be employed to enhance texture and depth in designs, allowing for a more dynamic visual impact. By experimenting with varying layering strategies, printers can discover unique effects that elevate their products in the marketplace.

Additionally, adjusting temperature settings for heat presses based on fabric and film requirements is critical. Incorrect settings can lead to issues such as peeling or fading of prints, undermining the quality of the final product. A careful calibration of these parameters ensures that each print adheres smoothly and maintains its integrity during use.

The Importance of Proper Curing in DTF Printing

Curing is a crucial step in the DTF printing process that significantly enhances the durability of prints. Properly curing prints allows inks to adhere properly to fabrics, reducing the likelihood of issues such as fading or peeling. Understanding the specific curing requirements for different fabrics and inks is essential for producing high-quality garments.

Testing various curing methods, including time and temperature adjustments, is recommended for achieving optimal results. By identifying the best practices suited for individual printing setups, manufacturers can ensure the long-term quality and resilience of their printed products, ultimately leading to increased customer trust and satisfaction.

Frequently Asked Questions

What are DTF gangsheets and how do they benefit Direct to Film printing?

DTF gangsheets are specialized sheets used in Direct to Film (DTF) printing to print multiple designs simultaneously. This method significantly benefits producers by reducing material waste and improving efficiency, allowing for maximized production output while maintaining high-quality prints.

How can I optimize my designs for more efficient DTF gangsheets?

To optimize your designs for DTF gangsheets, focus on space management by aligning designs closely to minimize empty spaces. Ensure your design sizes are appropriate—large enough to be visually appealing yet fit well on the sheet—to maximize efficiency and production flow.

What printing techniques should I fine-tune for better DTF gangsheets?

For superior DTF gangsheets, fine-tune your layering techniques to enhance color vibrancy, and adjust your heat press temperature settings based on fabric type. Properly mastering these printing techniques can lead to stunning results and greater product durability.

What quality materials should I select for my DTF printing process?

Choosing high-quality DTF inks and appropriate film thickness is crucial. Opt for inks that ensure vivid colors and compatibility with your printer. Additionally, select films that are suitable for the fabrics you work with to achieve optimal adhesion and longevity in your prints.

Why is proper curing essential in the production of DTF gangsheets?

Proper curing is vital in DTF printing as it enhances the durability of your prints and prevents issues such as peeling or fading. Ensuring that prints are cured at the right temperature and duration allows the inks to firmly bond with the fabric, contributing to improved wash fastness.

What are some tips for streamlining my workflow when using DTF gangsheets?

To streamline your workflow in DTF gangsheets production, create an organized production flow that clearly defines each step—from design to printing and pressing. Consider incorporating automation to reduce manual tasks and increase overall efficiency in your printing setup.

| Key Point | Description |

|---|---|

| Introduction to DTF Gangsheets | DTF gangsheets allow multiple designs on a single film sheet, maximizing productivity and reducing waste. |

| Understanding DTF Gangsheets | DTF printing transfers images onto various fabrics, with gangsheets enabling simultaneous design printing for efficiency. |

| Optimize Your Design | Manage space effectively on the sheet and ensure designs are appropriately sized for visibility and fit. |

| Select Quality Ink and Film | High-quality inks and film ensure vibrant colors and durability, essential for successful prints. |

| Fine-tune Your Printing Techniques | Adjust layering and temperature settings for improved print quality and adherence to fabrics. |

| Ensure Proper Curing of Prints | Curing at the correct temperature and time is crucial for durability and wash fastness of prints. |

| Streamline Your Workflow | Organized production flow and automation can significantly boost efficiency and reduce production time. |

| Experiment with Textures and Finishes | Testing different finishes and textures can enhance product appeal and attract more customers. |

Summary

DTF gangsheets represent a revolutionary approach in garment decoration, maximizing production efficiency and quality. By optimizing designs, selecting high-quality materials, perfecting printing techniques, ensuring proper curing, streamlining workflows, and experimenting with finishes, businesses can significantly enhance their output. As the DTF printing landscape continues to evolve, staying informed about advancements and engaging with the community will further refine production processes. This methodology not only positions businesses for success but also allows them to deliver exceptional products that resonate with customer expectations.