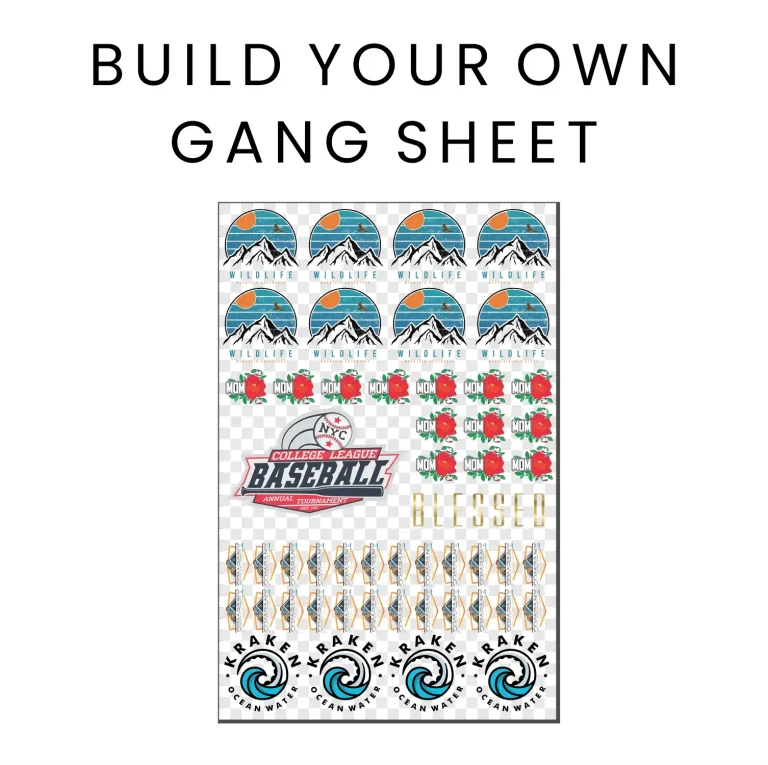

DTF gangsheet builder: Which layout is right for you?

DTF gangsheet builder is revolutionizing how apparel shops plan prints, blending automation with strategic design. By optimizing DTF printing efficiency, it helps maximize sheet usage and reduce reprints. Compared with manual layout for DTF, the builder lowers risk of human error and speeds throughput. Standardized margins and tile sizing support a clearer gangsheet vs manual layout decision for teams handling larger runs. For operations aiming to cut waste, adopting DTF sheet optimization practices alongside automation can yield measurable cost savings.

Viewed through an alternative lens, the core idea centers on optimizing how designs are tiled on film and how the print workflow flows. Using terms like sheet tiling optimization, automated layout, and batch production efficiency, this framing communicates the same concept while avoiding repetitive phrasing. Other related notions include space utilization, color management, and substrate compatibility that resonate with printers seeking consistent results. By framing the topic this way, teams can compare automation versus manual planning in practical terms such as setup time, waste, and cost per print. In short, the topic expands beyond a single tool to encompass process design, standardization, and the strategic balance between control and scalability.

Frequently Asked Questions

How does a DTF gangsheet layout tool improve DTF printing efficiency compared to manual layout for DTF projects?

A DTF gangsheet layout tool automatically tiles designs, computes bleed and margins, and aligns color separations, boosting DTF printing efficiency by reducing setup time and human error. It packs more designs per sheet, lowers material waste, and delivers more consistent results, whereas manual layout for DTF offers precise creative control but tends to be slower and more labor-intensive, especially on complex or nonstandard substrates.

What is the difference between gangsheet vs manual layout for DTF, and how should you approach DTF sheet optimization when choosing between them?

Gangsheet layout prioritizes standardization and speed, maximizing sheet utilization for high-volume runs and consistent output, while manual layout prioritizes flexibility and exact placements for bespoke designs. For best DTF sheet optimization, assess your order mix, run volume, and tolerance for waste; many shops succeed with a hybrid approach—using gangsheet layout for bulk production and manual layout for exceptions or artful placements.

| Aspect | Description |

|---|---|

| DTF gangsheet builder | A tool that automatically arranges multiple designs on a single film sheet, optimizing space, bleed, margins, color separations, and tile sizes; reduces manual work and scales for high-volume orders. |

| Manual layout | Hand-arranged designs in a design program, offering maximum creative control for nonstandard sheet sizes and precise placements; typically more time-consuming and prone to human error. |

| Efficiency & Throughput | DTF gangsheet builders increase sheet utilization and reduce setup time; manual layout is often better for small runs but slower per design. |

| Cost & Waste | Gangsheet layouts tend to minimize waste and ink consumption when used correctly; manual layouts may produce higher waste if not carefully planned. |

| Consistency & Quality Control | Gangsheet builders promote consistency with standardized spacing, margins, and color management; manual layout relies on operator discipline and can vary. |

| Learning curve & maintenance | Gangsheet setup requires initial templates and occasional maintenance but offers strong ROI for ongoing production; manual layout has a shorter initial learning curve but can be more labor-intensive over time. |

| Flexibility vs standardization | Gangsheet emphasizes standardization and speed; manual layout maximizes flexibility for unusual designs or bespoke requests. |

| Workflow fit & decision criteria | A hybrid approach often works: use a gangsheet builder for bulk work and reserve manual layout for exceptions; consider investing in a robust gangsheet workflow for ultra-high volumes. |

| Best practices | Define goals, map typical orders, standardize templates, test parallel jobs, and train operators to understand both methods. |

| Practical tips for sheet optimization | Plan sheet layout, use consistent margins and bleed, optimize for substrate, leverage color management, account for offcuts, and maintain clean file hygiene. |

| Tools & software considerations | Gangsheet tools automate tiling, bleed, and export; manual layout requires precise grid-based placement; consider a hybrid toolkit and evaluate ROI. |

Summary

DTF gangsheet builder is a strategic option for modern shops aiming to boost throughput while maintaining print quality and color accuracy. This discussion contrasts a DTF gangsheet builder with manual layout, outlining when to rely on automation for bulk, repeatable designs and when to preserve manual control for bespoke work. Many shops find the best results by blending both methods: automate bulk production with a gangsheet builder and reserve manual layout for exceptions. By defining clear goals, mapping typical orders, standardizing templates, testing thoroughly, and training your team, you can optimize DTF printing efficiency, reduce waste, and choose the workflow that best fits your operation.