DTF Gangsheet Builder: Unlocking Vibrant Apparel Designs

The DTF Gangsheet Builder stands at the forefront of revolutionizing the custom apparel printing landscape, showcasing the remarkable potential of DTF (Direct-to-Film) technology. This innovative tool enables designers to craft vibrant designs effortlessly, enhancing their creativity while improving production efficiency. By allowing multiple designs to be printed simultaneously on a single sheet, the DTF gangsheet builder not only maximizes material usage but also minimizes waste, making it an eco-friendly option. As businesses increasingly turn to gangsheet printing, they embrace the cost-effectiveness and ease-of-use that this technology offers, ensuring that even newcomers can produce professional-grade prints. In this blog post, we will explore the advantages of the DTF gangsheet builder and its impact on the future of garment decoration.

In the realm of custom clothing, the DTF gangsheet constructor is a game-changer for those harnessing the power of Direct-to-Film printing methods. This sophisticated software simplifies the process of creating intricate transfer designs, boasting the capabilities to produce stunningly vivid prints across various fabric types. As the demand for tailored apparel surges, utilizing gangsheet technology allows print businesses to streamline their operations while adhering to budgetary constraints. From vibrant graphical representations to intricate details, this tool empowers designers to explore limitless creative possibilities. Moving forward, understanding the nuances and benefits of DTF gangsheet technology will be imperative for those looking to thrive in the competitive custom apparel market.

Understanding DTF Printing Technology

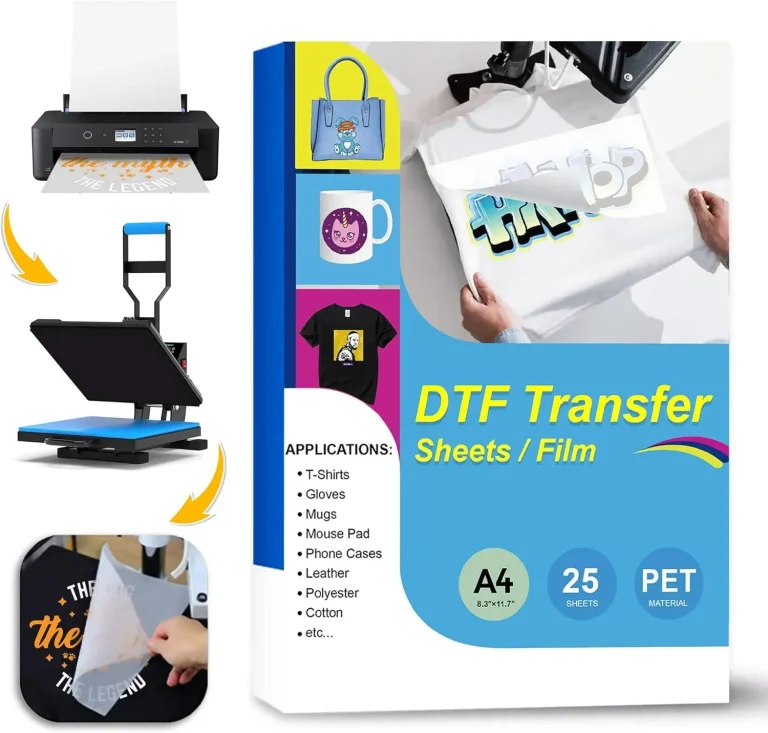

DTF printing, or Direct-to-Film printing, is an innovative technology that enables seamless transfers of designs onto fabrics. Unlike traditional printing methods that directly apply ink to garments, DTF printing utilizes a special film and adhesive to ensure that vibrant designs adhere to various materials. The process begins by printing the design onto a film, which is then coated with an adhesive powder, melted, and subsequently heat-pressed onto the fabric. This technology stands out because it allows for exceptional detail and color vibrancy, making it ideal for brands eager to make a strong visual impact.

The flexibility of DTF printing also means it can cater to various fabric types, including cotton, polyester, and blends, providing designers with a broad canvas for creative exploration. As the technology evolves, the quality of prints continues to improve, with advancements in ink formulations contributing to longer-lasting and more stunning outputs. Businesses are increasingly turning to DTF printing due to its blend of quality and cost-effectiveness, paving the way for creative ventures that can be tailored to consumer preferences.

Benefits of DTF Gangsheet Printing

The DTF gangsheet printing method presents a slew of benefits unique to its setup. One of the most significant advantages is cost efficiency; printing multiple designs on a single film transfer can dramatically reduce the overall material costs and time associated with production runs. This is particularly advantageous for custom apparel printing, where small batch orders are becoming increasingly popular. By utilizing a gangsheet builder, businesses can optimize their resources while scaling production to meet fluctuating demands.

Another benefit is the ability to produce vibrant designs without compromising on the quality of each individual print. Each design printed on a gangsheet can achieve the same level of detail and color vibrancy as traditional methods while leveraging the cost savings inherent in this process. This positions DTF printing as a competitive alternative to traditional methods, especially in markets where creativity and quality are crucial for brand differentiation.

Innovations Driving DTF Printing Forward

Recent advancements in DTF printing technologies have revolutionized how printers engage with this innovative medium. Among these innovations are improved ink formulations that enhance color vibrancy and longevity, ensuring that prints maintain their brilliance even after multiple washes. Enhanced adhesive technologies also play a pivotal role, as they facilitate better adhesion between the transferred design and the fabric, ultimately leading to higher customer satisfaction.

Moreover, many printers are integrating automated software tools within their processes to streamline the design layout and printing phases. The combination of these innovations not only enhances production speed but also reduces error rates, allowing businesses to operate more efficiently and effectively. As the technology continues to evolve, staying abreast of these innovations is crucial for businesses aiming to maintain a competitive edge in the custom apparel market.

Market Trends Influencing DTF Printing Popularity

The rise of DTF printing aligns with several macro trends within the clothing industry, particularly the growing demand for customized apparel. Customers increasingly seek unique, personalized products that reflect their individuality. DTF technology perfectly meets these demands by allowing for small-run productions and intricate designs, making it accessible for businesses that cater to niche markets.

Furthermore, today’s consumers are more environmentally conscious than ever, prompting brands to adopt sustainable practices. The DTF printing process minimizes waste by efficiently using materials and reducing excess. This not only meets consumer expectations for sustainability but also positions brands as leaders in environmentally-friendly initiatives within the apparel industry. As such, the adoption of DTF gangsheet printing becomes more critical for businesses wanting to maintain relevance in a rapidly evolving market.

Educational Resources for DTF Enthusiasts

For those venturing into DTF printing, numerous resources are available to aid in the learning process. Comprehensive online guides and tutorials can assist beginners in grasping the basics of DTF gangsheet builders and the printing process itself. Websites like Printavo and T-Shirt Magazine offer detailed insights into the machinery, the printing processes, and the latest innovations that enhance user experience. These materials are essential for anyone looking to tap into this modern method of custom apparel printing.

Additionally, community support forums play a crucial role in knowledge sharing among DTF printing enthusiasts. Engaging with experienced printers can provide newcomers with real-world insights and troubleshooting tips that textbooks often overlook. By leveraging these resources, individuals can navigate the complexities of DTF printing with greater confidence, improving their skills over time and contributing to the vibrant community built around this exciting technology.

The Future of DTF Gangsheet Printing

As DTF gangsheet printing gains traction, its future appears exceedingly bright owing to ongoing advancements in technology and changing consumer preferences. The printing sector is continuously evolving, and adopting innovative methods like DTF will undoubtedly remain at the forefront of market trends. The increasing demand for unique apparel designs combined with the efficiency and cost-effectiveness of DTF technology will drive more businesses to explore this avenue.

Moreover, as sustainability continues to influence consumer behavior, DTF printing aligns with eco-friendly practices by reducing waste and improving resource efficiency. Looking ahead, those in the custom apparel space who embrace DTF technology will not only enhance their product offerings but will also position themselves favorably in an increasingly competitive environment. The synergy between creativity, sustainability, and technological innovation is expected to shape the future of apparel printing significantly.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a tool used in DTF (Direct-to-Film) printing that allows users to design and arrange multiple prints on a single transfer film sheet. This method maximizes material efficiency, reduces waste, and simplifies the production process, enabling businesses to create vibrant designs quickly and economically.

What are the benefits of using DTF printing for custom apparel?

DTF printing provides several benefits for custom apparel, including vibrant color output, cost efficiency through gangsheet printing, and ease of use. It allows for intricate designs to be printed rapidly, making it ideal for small batches or personalized items, appealing to today’s market for unique garments.

How does the DTF Gangsheet Builder contribute to cost savings in production?

By allowing multiple designs to be printed on one gangsheet, the DTF Gangsheet Builder minimizes material waste and reduces the overall printing costs per item. This is especially advantageous for businesses that produce custom apparel, as they can save on both resources and time.

What makes the DTF Gangsheet Builder user-friendly for beginners?

The DTF Gangsheet Builder is specifically designed with an intuitive interface that simplifies the design process. This accessibility enables beginners and those with little experience in custom apparel printing to produce professional-quality prints without a steep learning curve.

What recent advancements in DTF technology enhance the Gangsheet Builder’s performance?

Recent advancements in DTF technology include better ink formulations for vibrant colors and durability, improved adhesion techniques for lasting prints, faster drying times for increased production efficiency, and automated software tools that streamline the design and layout process.

Why is sustainability a crucial factor in adopting DTF Gangsheet printing?

Sustainability is critical as DTF gangsheet printing reduces waste by maximizing the use of transfer films. With increasing consumer demand for eco-friendly practices, businesses can align their offerings with sustainable values while leveraging the efficient capabilities of DTF printing.

| Key Points | Details |

|---|---|

| What is DTF Gangsheet? | DTF gangsheet printing allows multiple designs on a single transfer film sheet, enhancing production efficiency and minimizing waste. |

| Advantages of DTF Gangsheet Builder | 1. Cost Efficiency: Reduces production costs by enabling simultaneous printing of multiple designs. 2. Ease of Use: User-friendly interfaces encourage creativity even for beginners. 3. Vibrant Color Output: Produces eye-catching, detailed prints on various fabrics, ideal for fashion apparel. |

| Technological Advancements | – Improved ink formulations for better color and durability. – Enhanced adhesion techniques for long-lasting prints. – Faster drying times to increase production speed. – Automated tools to simplify design processes. |

| Market Trends | – Rising demand for customization and personalized items. – Increasing sustainability concerns aligning with waste minimization through DTF gangsheet. |

| Educational Resources | – Printavo Blog: Innovations in DTF printing and gangsheet creation. – T-Shirt Magazine: Benefits of DTF printing for garment decoration. – Screen Printing Magazine: Information on techniques related to DTF technologies. |

Summary

DTF Gangsheet Builder represents a revolutionary tool in the printing industry, enhancing the way businesses and designers approach custom garment decoration. This innovative technology simplifies the process of creating high-quality designs while efficiently utilizing materials and minimizing waste. As the market trends indicate a growing preference for customization and sustainability, the DTF gangsheet builder stands out by enabling vibrant and durable prints that cater to both small and large-scale production needs. Embracing this technology not only enhances creativity but also aligns with ecological considerations, making it an essential asset for any apparel business aiming to thrive in today’s competitive landscape.