DTF Gangsheet Builder: Top Tips for Mastering Your Prints

The DTF Gangsheet Builder is revolutionizing the world of Direct-to-Film (DTF) printing by streamlining the gangsheet design process like never before. With DTF technology, users can create vibrant, high-quality prints that are perfectly tailored for various fabrics, significantly reducing material waste. This innovative tool marries advanced print quality with user-friendly design, making it easier for both beginners and professionals to bring their ideas to life. As the demand for custom apparel grows, mastering your DTF Gangsheet Builder becomes an essential skill for achieving optimal results in your printing projects. Throughout this article, we’ll explore tips and techniques that will enhance your workflow and ensure your designs stand out in today’s competitive market.

In the realm of custom apparel production, mastering the art of Direct-to-Film (DTF) printing technology is crucial for achieving excellent results. The process involves creating gangsheet designs that allow multiple graphics to be printed on a single film, optimizing both efficiency and resource use. As DTF printing continues to grow in popularity, understanding the nuances of gangsheet construction and print quality is vital. Embracing effective techniques and high-quality materials can dramatically elevate the final products you deliver to your customers. In this guide, we’ll uncover essential tips for navigating the complexities of DTF print production.

The Advantages of DTF Printing Technology

DTF printing technology stands out in the realm of fabric printing due to its unique process, which directly applies designs to a special film that is then transferred to the fabric with precise heat and pressure. This method not only results in vibrant colors but also offers exceptional durability, making it a preferred choice for businesses looking to produce high-quality apparel. The versatility of DTF technology allows for intricate designs and patterns that can cater to a variety of fabric types, enhancing its appeal to fashion designers and custom apparel creators alike.

In comparison to traditional screen printing, DTF technology significantly reduces setup times and minimizes waste. With the ability to print multiple designs in one gangsheet, producers can optimize their material use and time efficiently. This efficiency in production not only cuts down costs but also allows for rapid turnaround times, making it a winning choice for on-demand printing customers who expect immediate delivery.

Mastering Your DTF Gangsheet Builder

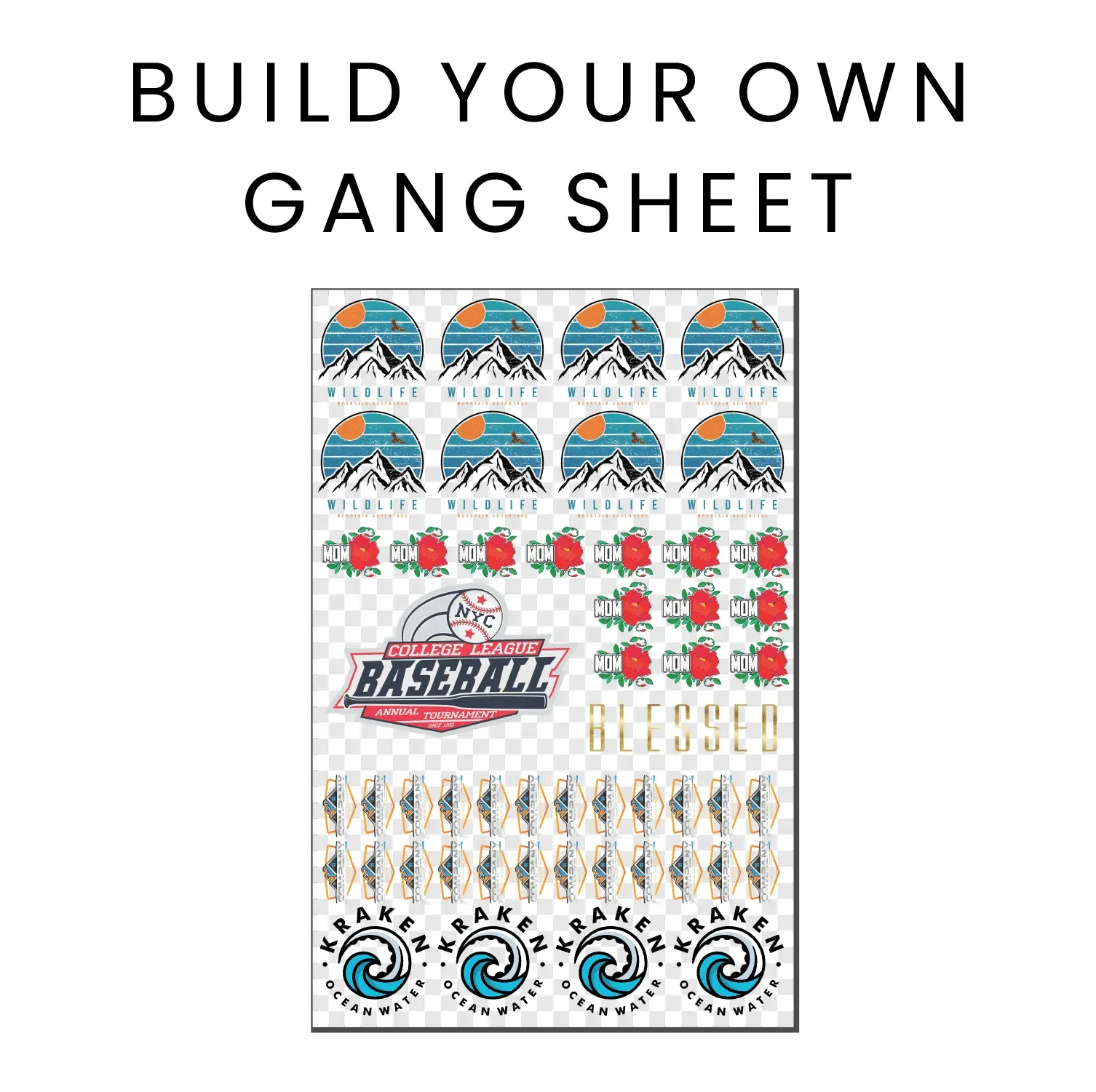

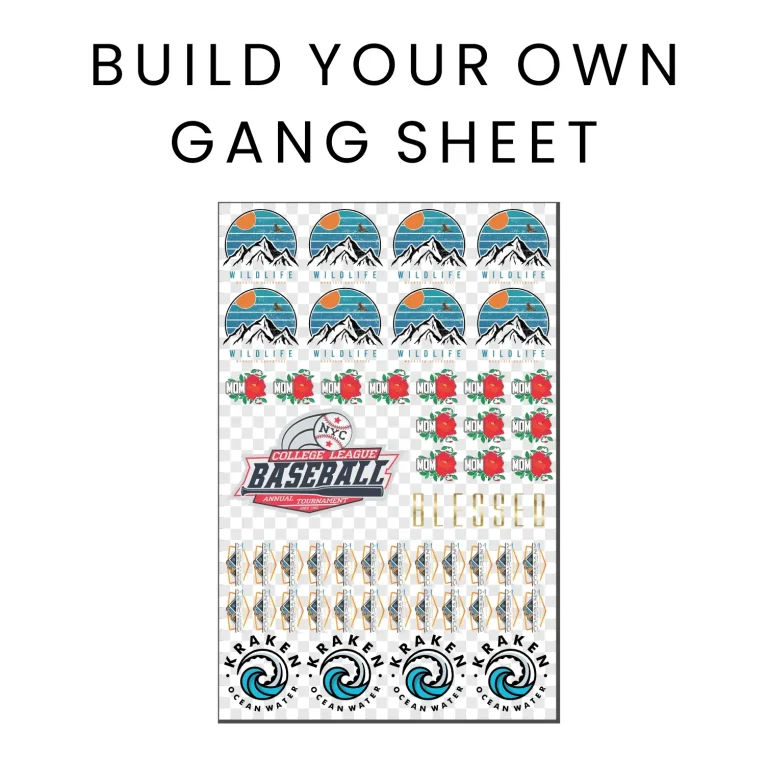

A DTF gangsheet builder is an essential tool that allows users to maximize the efficiency of their printing process. Understanding how to navigate this software effectively can dramatically alter the output quality and material usage. For example, incorporating precise measurements and layout adjustments can help ensure that designs fit perfectly on the gangsheet, thus significantly reducing fabric waste and enhancing print quality.

Furthermore, a well-optimized DTF gangsheet builder aids in the creation of intricate designs without compromising the final product’s clarity. This level of mastery not only results in visually stunning apparel but also minimizes trial and error during production runs. With practice and familiarity with the builder, users can experiment with different layouts and discover innovative ways to enhance both productivity and artistic output.

The Importance of High-Quality Design Software

The choice of design software plays a critical role in the DTF printing process. Utilizing advanced design programs like Adobe Illustrator or dedicated DTF software can streamline the creation of gangsheet layouts, allowing you to leverage features that optimize design presentation and accuracy. These tools not only help in establishing the dimensions necessary for gang prints but also enhance the overall design quality, crucial for achieving vibrant colors and intricate details.

Moreover, investing time in mastering these software solutions can aid in error reduction during the design phase. Features like layer management, color matching, and exporting settings specifically for DTF printing ensure that whatever appears on the screen translates accurately onto the fabric. This precision is vital for businesses seeking to maintain a consistent print quality that meets customer expectations.

Effective Artwork Preparation Techniques

Artwork preparation is a decisive step in ensuring successful DTF prints, and it begins with creating high-resolution images. A minimum of 300 DPI is recommended to ensure that designs maintain their integrity during the transfer process. Additionally, using layers for different design elements allows for flexibility and adjustments without compromising the quality of the final print.

Understanding the importance of margins is also critical. Keeping all design elements within the safe margins of the gangsheet prevents any part of the artwork from being lost during the printing process. Furthermore, utilizing transparent backgrounds can help prevent excess ink usage, contributing to a more cost-effective and environmentally friendly print approach.

Maximizing Gangsheet Efficiency to Reduce Waste

The ability to maximize gangsheet efficiency is one of the standout features of DTF printing. By employing intelligent arrangement tactics, such as clustering designs or rotating elements to better fit the printable area, users can significantly reduce waste and improve cost-effectiveness. This not only saves valuable printing materials but also streamlines the overall process, allowing for greater productivity.

When adjusting layouts for various fabric sizes, understanding the capabilities of your printer becomes essential. By tailoring designs to fit specific dimensions and retaining uniform spacing, you can ensure that every part of the gangsheet is utilized effectively. This strategic approach not only enhances efficiency but also helps in achieving a higher quality of print outcomes.

Engaging with the DTF Printing Community for Growth

Becoming an active participant in the DTF printing community can provide invaluable benefits for anyone looking to enhance their skills in DTF technology. Online resources like tutorial videos, forums, and group discussions offer a treasure trove of knowledge from experienced professionals, enabling users to troubleshoot their challenges and gain insight into best practices.

Social media platforms like Facebook and dedicated forums serve as excellent channels for networking with other DTF enthusiasts. These connections not only foster collaborative learning experiences but also keep users informed about emerging trends and new technologies, which can ultimately lead to improved competitiveness in the custom apparel niche.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it work?

A DTF Gangsheet Builder is a software or tool that optimizes the Direct-to-Film (DTF) printing process by allowing users to design multiple images on a single sheet of film. This method minimizes waste and maximizes print quality, ensuring efficient use of materials in gangsheet design.

How can I improve the print quality when using a DTF Gangsheet Builder?

To enhance print quality using a DTF Gangsheet Builder, ensure your artwork is high resolution (at least 300 DPI), use quality DTF films and inks, and maintain your printing equipment. Proper artwork preparation, including transparency and layering, also helps achieve vibrant and precise results.

What materials should I choose for successful DTF printing with a gangsheet builder?

When using a DTF Gangsheet Builder, opt for high-quality DTF films with strong adhesive properties and durable inks. These materials significantly impact the longevity and vibrancy of your prints, ensuring that your designs adhere well to various fabrics.

What are some common mistakes to avoid with DTF Gangsheet Builders?

Common mistakes include not preparing artwork correctly, neglecting printer maintenance, and failing to perform test prints. Additionally, overlooking optimal gangsheet layouts can lead to wasted materials, hence it’s crucial to fully utilize the printing area effectively.

How can I efficiently calculate gangsheet layout for DTF printing?

To efficiently calculate a gangsheet layout for DTF printing, arrange design elements to maximize the printable area by overlapping or clustering designs creatively. Adjust layouts according to your printer’s dimensions to ensure you make the most of your film space and reduce waste.

What benefits does DTF technology offer for custom apparel printing?

DTF technology facilitates high-quality transfers onto fabric with vibrant colors and intricate designs while allowing for versatility. A DTF Gangsheet Builder enhances this process, providing the ability to combine multiple designs in one print run, ultimately saving time and reducing costs.

| Key Point | Description |

|---|---|

| Understanding DTF Technology | DTF allows direct printing onto a special film, which is then transferred to fabric, providing vibrant colors and intricate designs. |

| Choosing the Right Software | Using tools like Adobe Illustrator improves design efficiency and ensures print-ready layouts, avoiding waste. |

| Artwork Preparation | Ensure artwork is high resolution (300 DPI), use layers for adjustments, and remain within safe margins to prevent cutoffs. |

| Calculating Gangsheet Efficiency | Utilize space efficiently by arranging designs creatively and adjusting layouts for different fabric sizes. |

| Choosing Quality Materials | Select strong adhesive films and high-quality inks for durability and vibrancy in prints. |

| Test Printing | Conduct test prints to determine optimal settings for fabric types and ensure quality transfers. |

| Community Resources and Tutorials | Engage with online communities for tips, tutorials, and troubleshooting, enhancing skills and knowledge. |

| Regular Maintenance | Keep equipment clean, store materials properly, and calibrate printers to maintain high-quality outputs. |

Summary

DTF Gangsheet Builder is pivotal for those looking to enhance their printing capabilities. By mastering this tool and implementing the top tips provided—from understanding DTF technology to utilizing community resources—you can significantly improve your printing efficiency and quality. Taking meticulous care in artwork preparation, choosing quality materials, and conducting regular maintenance will elevate your prints, making them stand out in a competitive market. Embracing these practices ensures that you stay ahead in the realm of Direct-to-Film printing, ultimately leading to greater success in your apparel business.