DTF Gangsheet Builder: Tips, Workflows, and Templates

DTF Gangsheet Builder is a powerful, time-saving tool for anyone involved in direct-to-film printing, from hobbyists to professional studios. Designed to streamline design, layout, and export of gang sheets, it helps batch multiple designs and keep color consistent across garments, trims waste, and speeds onboarding. To maximize efficiency, users can align assets with grids, manage color separation, and produce print-ready sheets that feed a reliable DTF printing workflow across multiple substrates and garment types. With built-in templates, the tool supports gangsheet templates and color control, reducing waste and accelerating production, while offering robust safety checks. Whether you’re a shop owner, designer, or printer, these practical tips and templates help you turn complexity into confidence and support ongoing growth.

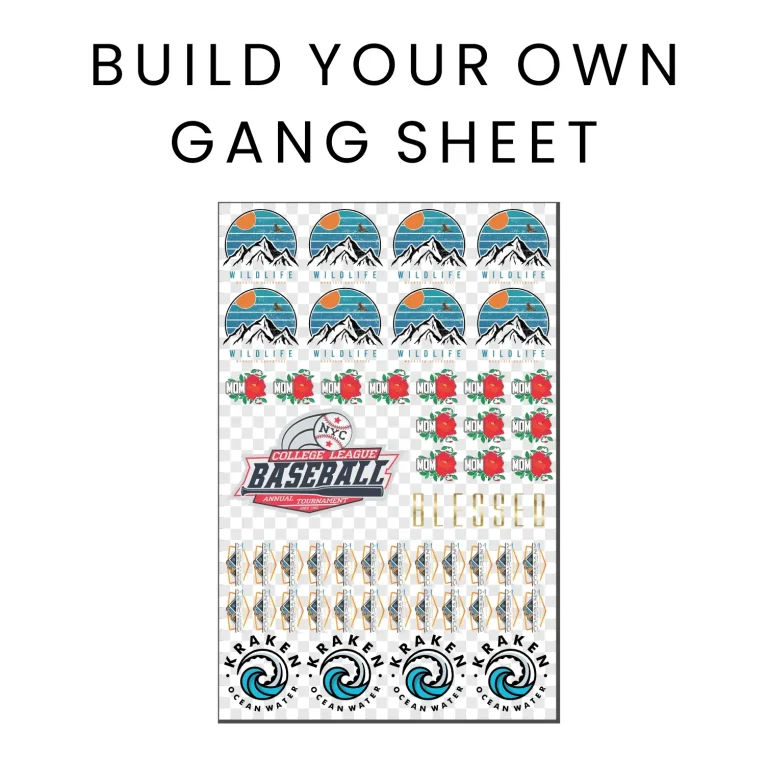

In other terms, this platform acts as a smart layout manager for multi-design transfers, turning scattered artwork into a cohesive print plan. Think of it as a grid-based canvas that bundles several designs into a single print-ready sheet, with precise spacing, safe areas, and clear design IDs. From a semantic perspective, the concept aligns with terms such as print preparation tool, digital transfer grid, and template-driven workflow, which helps search engines connect related topics. Emphasizing color management, asset organization, and reusable templates supports scalable production, reduces waste, and enables teams to move from concept to clear, repeatable output.

DTF Gangsheet Builder: Streamline Your DTF Printing Workflow and Color Separation

The DTF Gangsheet Builder sits at the heart of the DTF printing workflow, enabling you to organize multiple designs on a single sheet with a precise grid, safe print areas, and well-defined bleed margins. By mastering layout and export steps, you can batch print dozens of designs in one run, reduce material waste, and maintain color consistency across different garments. This streamlined approach helps you move from planning to production with confidence and efficiency.

Leverage gangsheet templates within the builder to standardize margins, spacing, and color channels. A solid DTF color separation guide built into your workflow minimizes surprise hues and ink density issues, while a consistent palette simplifies the separation process. When you combine template-driven layouts with careful color management, you’ll find that the DTF garment printing tips you rely on—like predictable transfers, crisp edges, and reliable press timings—become repeatable results rather than guesses.

To keep production smooth, export a print-ready gangsheet with clear labels, design IDs, and notes for the press operator. This practice, along with a robust color management strategy, reduces rework and accelerates the path from design to print, supporting scalable output and higher overall quality.

Design to Print Mastery: Leveraging Gangsheet Templates for Efficient DTF Production

A clear design-to-print plan starts with preparing assets that scale well, defining a practical gangsheet layout, and placing designs with alignment guides. By emphasizing a solid DTF design to print process, you ensure high-resolution integrity, consistent color, and predictable transfer results across garments. This approach minimizes guesswork and helps you move from concept to production quickly.

Color separation and management are central to consistent results. Build a printer-specific color palette, convert artwork to the appropriate color models, and verify separations on test sheets. Integrating DTF color separation practices with your gangsheet workflow reduces drift and yields reliable color fidelity during heat pressing. Practical DTF garment printing tips—such as monitoring ink density and adjusting for fabric color—are easier to apply when designs are organized within a reusable template system.

Templates are the backbone of efficient workflows. Create a library of gangsheet templates that cover standard sheet sizes and common design sizes, plus pre-defined margins, bleed values, and color channels. This template-centric approach accelerates new jobs, ensures consistency, and supports scalable production while keeping quality top of mind through ongoing design to print iterations.

Frequently Asked Questions

How can the DTF Gangsheet Builder improve your DTF printing workflow and color separation across multiple designs?

The DTF Gangsheet Builder centralizes asset management, grid layout, and color handling to streamline the DTF printing workflow. By using gangsheet templates and a defined safe print area, you can batch multiple designs on one sheet, reduce waste, and maintain color fidelity across garments. Export the gangsheet in high-quality formats and apply a consistent color palette that aligns with your printer and the DTF color separation guide to minimize surprises on press.

What are best practices when designing and exporting gang sheets with the DTF Gangsheet Builder for reliable alignment and color fidelity in DTF garment printing?

Start with a clear design-to-print plan and rely on gangsheet templates to lock in layout, margins, and color channels. Use consistent naming conventions, batch processing, and template libraries to speed setup and reduce errors. Run small test prints to verify alignment and color output—these are essential DTF garment printing tips. When exporting, choose formats that preserve transparency and color integrity and include a print-ready guide with design IDs and notes to support the press operator.

| Aspect | Key Points |

|---|---|

| What is the DTF Gangsheet Builder? | A tool to design, lay out, and export gang sheets for DTF printing to batch multiple designs in one run, reducing waste and maintaining color consistency. |

| Core concepts | Grid layout; Safe print area; Bleed margins; Color separation; Export options |

| Practical workflow steps | 1) Prepare assets with high-resolution designs and color profiles (e.g., SRGB). 2) Define gangsheet layout and grid. 3) Place and align designs with guides. 4) Manage color separation and color output. 5) Review, export (PNG/TIFF at high resolution), and prepare for print. 6) Production QC and alignment checks. 7) Cut, press, and verify transfers. |

| Templates and workflows | Templates provide reusable layouts and color settings, including size-to-grid templates, margin/bleed templates, color-management templates, label templates, and a template library. |

| Best practices | Plan design-to-print workflow; use consistent naming conventions; batch process where possible; validate color early; regularly update templates to reflect real-world results. |

| Real-world use cases | Examples show reduced production time and increased consistency. For instance, a small shop can cut press time by a notable margin using grid planning, color separation, and template-driven layouts; template-driven workflows can halve setup time for new orders. |

| Common pitfalls | Misalignment; Color drift; Overcrowded sheets; Inconsistent labels. Mitigate with snap-to-grid, defined color profiles, proper margins, and clear labeling. |

Summary

DTF Gangsheet Builder enables you to plan, layout, and ship multi-design transfers with confidence. By defining grid layouts, safe print areas, and robust color separation, it helps reduce waste, maintain color fidelity, and speed up production. Templates and standardized workflows turn complex client orders into repeatable, scalable processes, making it easier for small shops, printers, or freelance designers to grow. As you gain experience, you’ll build a library of reusable layouts that streamline future jobs, delivering consistent, high-quality transfers across garments.