DTF Gangsheet Builder: The Ultimate Guide for Print Shops

DTF Gangsheet Builder unlocks new levels of speed and accuracy for garment decorators, empowering teams to plan complex designs across multiple garments with confidence and traceability, while maintaining tight control over color accuracy, placement, margins, and production documentation, and it supports rigorous prepress records, centralized asset management, and straightforward versioning to keep projects aligned from concept to customer. It powers DTF printing by grouping designs on larger transfer sheets, a capability that substantially reduces the number of printer passes, lowers substrate consumption, and shortens the overall timeline from concept to finished garment, without sacrificing detail or color fidelity, while providing clearer handoffs between design, prepress, and production teams. With these capabilities, teams can explore various layout strategies, automate routine placements, and validate alignment before any production step, all while preserving consistent margins and avoiding misfeeds or color drift across batches, enabling smoother handoffs to finishing and packaging. The result is a more resilient prepress pipeline, reduced rework, faster turnarounds, and the ability to scale operations during peak periods without compromising quality or timely delivery, with teams able to sustain accuracy as they expand client rosters and diversify product lines. For shops seeking practical, bottom-line improvements, adopting this approach offers a clear path from artwork to finished garments with predictable results, easier training for staff, and a framework for continuous optimization that adapts to changing demand.

Seen through an LSI-informed lens, this tool functions as a batch-layout solution that concentrates multiple artworks onto a single substrate plan to accelerate production and maintain consistency. Other terms that reflect the same idea include gangsheet layout manager, multi-design template, and sheet-optimization workflow, all pointing to a cohesive process that ties artwork, substrates, and finishing steps. By focusing on consistency, color fidelity, efficient file handling, and rigorous preflight checks, the approach supports scalable production planning, predictable lead times, and reliable outputs across orders. In practice, adopting this strategy reduces setup time, minimizes waste, and improves confidence in on-time delivery for customers, while offering a framework adaptable to changes in demand and product diversity.

DTF Gangsheet Builder: Maximize Throughput and Minimize Waste in Your Print Shop

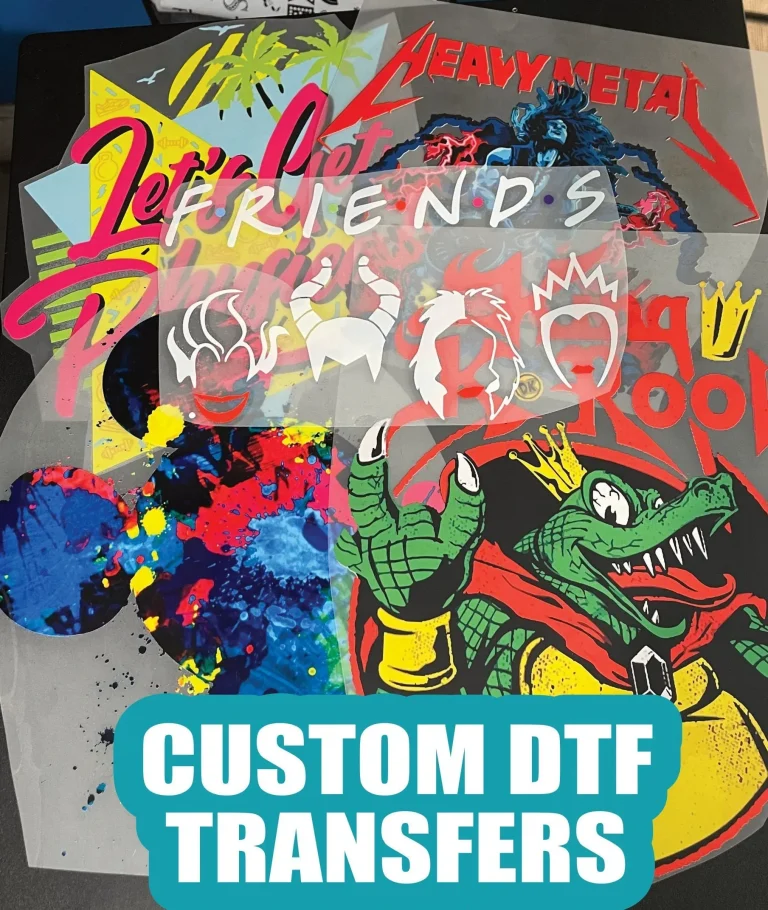

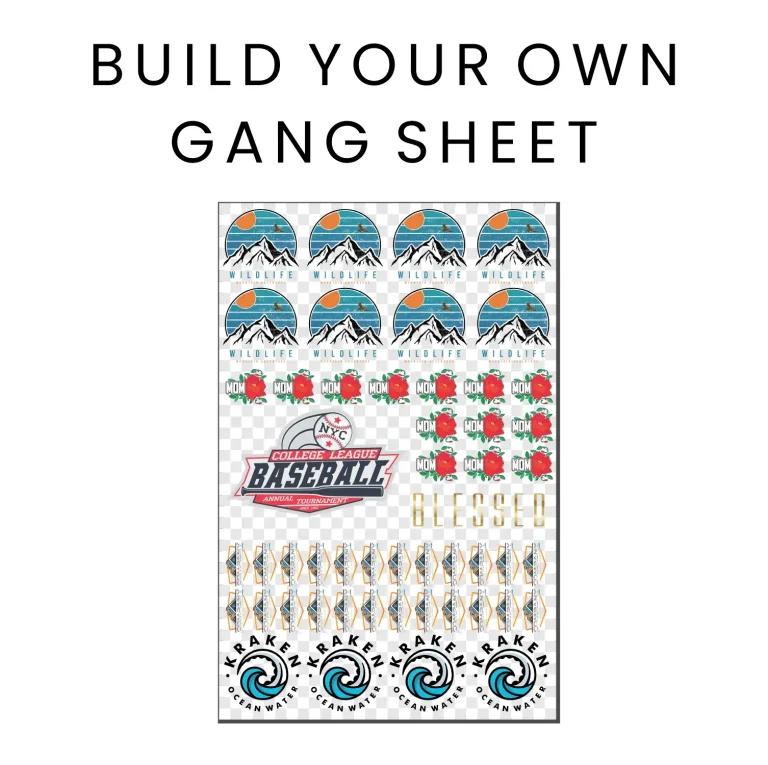

In the world of DTF printing, a well-executed gangsheet layout lets you place multiple designs on one DTF transfer sheet, cutting the number of print passes and reducing substrate waste. The DTF Gangsheet Builder is a tool that translates individual design files into optimized gangsheet configurations, boosting throughput and stabilizing color reproduction across prints. By grouping related designs and colorways, you can run dozens of garments per sheet while keeping each design legible and within margins.

With a reliable gangsheet workflow, print shops can shorten setup times, streamline prepress, and improve overall efficiency from design to delivery. The DTF Gangsheet Builder supports DTF design software and RIP integrations, ensures proper color management with embedded ICC profiles, and aligns with DTF transfer sheets for predictable outcomes. As a result, shops experience lower material waste, faster turnarounds, and more consistent results across runs.

This approach also simplifies downstream finishing such as contour cutting and heat pressing, because the designs arrive on a single sheet with precise positions, labeling, and a clear plan for packing and fulfillment.

Integrating DTF Design Software with Gangsheet Printing to Optimize the Print Shop Workflow

Combining DTF design software with gangsheet printing creates a cohesive prepress and production pipeline. Designers prepare artwork in compatible color spaces, export to print-ready formats, and the gangsheet tool arranges layouts that maximize sheet usage while preserving critical details on DTF transfer sheets. This integration minimizes misfeeds and color drift, supporting consistent results across orders.

Best practices include standardized templates for common sheet sizes, automated file import, preflight validation, and tying gangsheet accuracy to inventory and finishing steps. By linking with the broader print shop workflow, color management, and substrate planning, shops can predict ink usage, optimize material orders, and improve on-time delivery. The combination of DTF printing, gangsheet printing, and robust DTF transfer sheets ensures a scalable operation as orders grow.

Frequently Asked Questions

How does the DTF Gangsheet Builder improve the print shop workflow during DTF printing?

The DTF Gangsheet Builder consolidates multiple designs onto a single transfer sheet, increasing throughput and reducing setup time. It integrates with your DTF printing workflow and design software to maintain color accuracy and minimize substrate waste, delivering a smoother, more predictable operation for your print shop.

What is a DTF gangsheet and how does it optimize gangsheet printing and color accuracy in DTF design software and transfer sheets?

A DTF gangsheet is a layout that places several designs on one transfer sheet for efficient production. The gangsheet builder optimizes spacing, margins, and color management, improving color accuracy and reducing misprints in gangsheet printing when used with DTF transfer sheets and DTF design software.

| Aspect | Key Points |

|---|---|

| What is a DTF Gangsheet Builder? |

|

| Benefits and goals |

|

| Who should use it? |

|

| Getting started |

|

| Design considerations |

|

| How to use in practice |

|

| Integrating with the print shop workflow |

|

| Best practices |

|

| Common pitfalls |

|

| Advanced tips |

|

| Real-world impact |

|

| Maintenance, compatibility, and future-proofing |

|

Summary

DTF Gangsheet Builder represents a practical, high-value addition to any print shop’s toolkit. By enabling efficient gangsheet layouts, it reduces waste, improves throughput, and provides a clearer path from artwork to finished garments. A thoughtful approach—covering layout optimization, color management, labeling, and integrated workflows—ensures you can capitalize on the benefits across a wide range of orders. If you’re looking to elevate your DTF printing operations, investing in a robust gangsheet builder is a strategic move that pays dividends in productivity, quality, and customer satisfaction.