DTF Gangsheet Builder: Maximize Your Printing Output

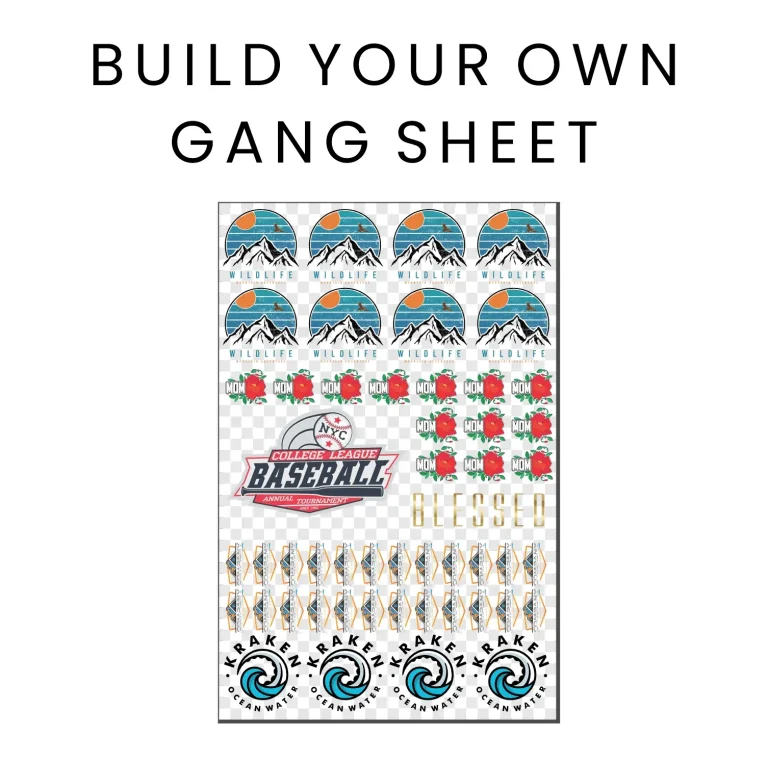

DTF gangsheet builder revolutionizes how shops plan multi-design transfers, turning scattered artwork into a cohesive, production-friendly layout. By organizing multiple designs on a single transfer sheet, it strengthens the DTF printing workflow and emphasizes efficient DTF gang sheet design. This approach boosts throughput, reduces waste, and supports maximizing DTF output across high-volume runs. You’ll also benefit from better color management and consistent results, a cornerstone of DTF printing optimization and reliable turnaround times. With practical tips and a clear path from setup to export, the builder helps you dial in powerful DTF heat press tips and deliver top-quality transfers.

Viewed through the lens of LSI, the concept can be described as a DTF transfer sheet designer or multi-design layout engine that optimizes space and alignment. This alternative framing emphasizes the same goal—efficient batch planning, consistent color application, and reliable transfer results—without relying on a single brand name. Other terms you might encounter include DTF layout optimizer and print-ready sheet planner, all pointing to a tool that complements the DTF printing workflow.

DTF Gangsheet Builder: Maximize Output and Cut Waste

Using a DTF gangsheet builder lets you map multiple designs onto one transfer sheet, optimizing the printable area and reducing waste. This approach is central to a smooth DTF printing workflow, helping you batch designs efficiently and keep colors aligned across all placements. By focusing on the DTF gang sheet design, you can increase throughput without sacrificing print quality, producing more transfers per run and lowering cost per unit.

To maximize results, set standard sheet sizes that fit your printer, establish margins, and maintain consistent color management. The builder’s export settings and layering options support a clean handoff to the DTF printer, ensuring your designs stay locked in place and ready for production. This contributes to maximizing DTF output across multiple jobs by reducing rework and material waste.

Practical workflow considerations include preparing artwork at high resolution, embedding color profiles, and using templates for common orders. Regularly validating gang sheets with a preview helps catch alignment or margin issues before printing, reinforcing the efficiency gains promised by a good DTF gangsheet builder.

DTF Printing Optimization: Layout, Color, and Heat Press Tips

DTF printing optimization hinges on thoughtful layout, color management, and repeatable press settings. From initial artwork prep to final transfer, aligning colors and scaling across the gang sheet supports consistent results and minimizes post-print adjustments. This is where a well-planned DTF printing workflow shows its value, particularly when you pair it with robust DTF heat press tips for transfer quality.

Key tips include pre-press warm-up, accurate dwell times, appropriate pressure for the chosen substrate, and controlled cooling after transfer. Incorporating DTF heat press tips such as maintaining even platen temperature and steady pressure helps prevent misregistration and improves wash durability across designs on the same sheet.

Further optimization comes from auditing completed gang sheets, using templates for repeat jobs, and integrating with order management. By continuously refining layouts, color settings, and press parameters, you unlock ongoing improvements in DTF output and overall production efficiency, which aligns with broader DTF printing optimization goals.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it impact the DTF printing workflow to maximize output?

A DTF gangsheet builder is software that lets you lay out multiple designs on a single gang sheet before sending them to your DTF printer. It improves the DTF printing workflow by increasing output per sheet, ensuring consistent color and placement, reducing waste, and speeding pre-press. How it works in practice: import artwork, arrange on a grid with proper margins and bleed, adjust scaling, preview the layout, and export a print-ready file (PNG or TIFF with embedded color profile) that your printer can use. Best practices include using high-resolution artwork (300 dpi or higher), maintaining a consistent color profile (CMYK), embedding fonts, and saving reusable templates. For best transfer results, pair it with DTF heat press tips.

How can a DTF gang sheet design strategy using a gangsheet builder optimize DTF printing optimization?

A well-planned gang sheet design strategy guides how you place multiple designs on each sheet to maximize printable area, minimize waste, and keep color and alignment consistent, all central to DTF printing optimization. Practical steps: set standard sheet sizes and grid rules; use templates for common orders; rotate or nest designs to fit more per sheet; group colors to reduce color changes; maintain safe margins and bleed; export with embedded color profiles and printer-ready settings; and, where possible, automate layouts or integrate with your order system. Common pitfalls to avoid include overcrowding, inconsistent artwork resolution, and neglecting margins.

| Topic | Key Points |

|---|---|

| Introduction | Maximize sheet usage, minimize waste; a DTF gangsheet builder arranges multiple designs on a single transfer sheet; improves throughput, reduces material costs, and enables faster turnaround times. |

| What it is and why it matters | Software that lays out all artwork on one gang sheet before printing; benefits include higher output per run, consistent color and placement, reduced waste, and faster workflow. |

| Getting started | Gather clean artwork, measure accurately, choose a standard sheet size; import designs, arrange on a grid, tweak scaling, and preview before printing; core workflow that lowers costs and speeds production. |

| Key terms | Gang sheet design, margins and bleed, color management, export settings. |

| Preparing artwork | Use high-resolution files (300 dpi or higher), maintain a CMYK color profile, embed fonts, separate layers by color if possible, and ensure safe margins. |

| Step-by-step approach | 1) Define sheet size; 2) Import designs and grid rules; 3) Arrange for maximum efficiency; 4) Manage color layers; 5) Preview; 6) Export with printer-ready settings. |

| Maximizing DTF output | Batch planning, standardized margins, optimized color management, space optimization, and regular audits to identify and reduce waste. |

| Practical heat press tips | Pre-press warm-up, appropriate time and pressure, test runs on similar fabrics, consistency in substrate, and post-press care. |

| Common mistakes | Overcrowding, ignoring margins, mixed resolution quality, poor color management, and exporting without color profiles. |

| Advanced tips | Automation where possible, templates for common layouts, integration with order management, and continuous optimization by tracking yield and time-to-press. |