DTF Gangsheet Builder: Maximize Production Efficiency Now

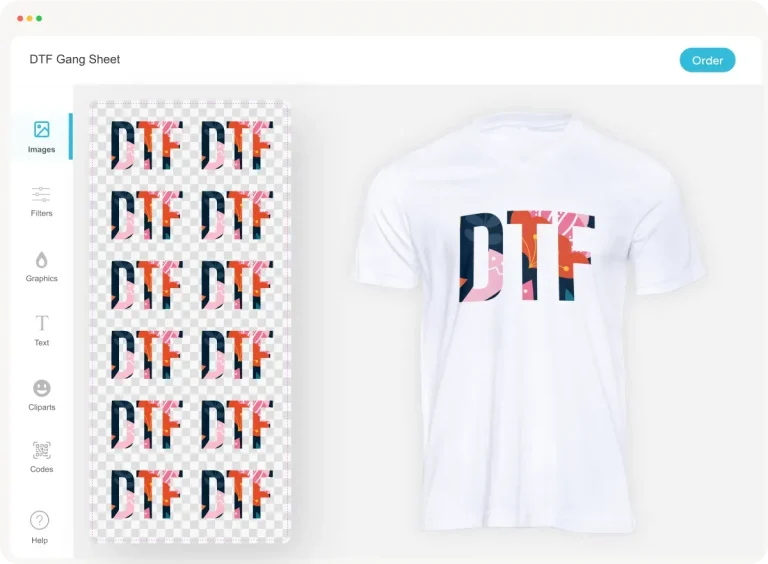

DTF Gangsheet Builder reshapes how shops approach customization by packing multiple designs onto a single sheet with precision, reducing manual steps and accelerating proofs. In the broader DTF printing workflow, it helps optimize layout, reduce waste, shorten prepress time, and align colors across orders. By automating gangsheet optimization, operators can increase batch printing with gang sheets without sacrificing color accuracy, while keeping substrate usage predictable. This translates to tangible production efficiency in DTF, with fewer setup steps and more consistent transfers that meet turnaround targets for clients. For best results, pairing the builder with heat transfer printing tips and disciplined workflow practices can maximize throughput while preserving print quality.

Viewed through alternative terms, a gang sheet designer, a layout automation tool, or a batch-layout planner coordinates multiple designs on one print run. Reframing with LSI-style terms, you can think of it as a prepress automation platform or production-layout optimizer that helps teams visualize space, margins, and color separation before printing. In practice this approach streamlines the production workflow, builds a reliable template library, and enables faster ramp-ups when demand surges while preserving transfer quality. Ultimately, these synonyms point to the same objective: maximize sheet utilization, reduce waste, and deliver consistent, market-ready results.

DTF Gangsheet Builder: Boosting Gangsheet Optimization for Higher Throughput

Leveraging the DTF Gangsheet Builder lets you automatically arrange multiple designs onto one printable sheet, maximizing gangsheet optimization. In a DTF printing workflow, tighter packing translates to higher throughput and lower per-design costs. With auto-layout, precise margins and bleed handling, and color-space awareness, you can fit more designs per batch while preserving legibility and color accuracy. This directly enhances production efficiency in DTF by reducing prepress time and the number of print cycles required for each job, enabling faster go-to-print across batch printing with gang sheets.

To get started, gather artwork, define your sheet size, import designs, run the optimization, calibrate color management, and save templates. The steps align with gangsheet optimization and batch printing with gang sheets, ensuring consistent results across runs. By validating with a preview before printing and using templates for repeat clients, you minimize setup time and maximize production efficiency in DTF, while keeping print quality intact.

Strategies for Batch Printing with Gang Sheets and Realizing Production Efficiency in DTF

Batch printing with gang sheets benefits from a disciplined approach: group similar garments, use grid-based layouts, and treat templates as reusable assets to reduce prepress time. A well-planned gangsheet strategy lowers setup time, minimizes color management adjustments between designs, and improves production efficiency in DTF by smoothing the path from file to print.

To scale effectively, track metrics like designs per sheet, substrate usage, and cycle time. Consider integrating with order management to auto-generate gang sheets from upcoming jobs, and run test prints to verify color and alignment. Apply heat transfer printing tips such as maintaining appropriate transfer temperature, pressure, and dwell time for each fabric to prevent misprints or misalignment, ensuring consistent results across batches in your DTF workflow.

Frequently Asked Questions

How does a DTF Gangsheet Builder boost production efficiency in a DTF printing workflow?

A DTF Gangsheet Builder automates the arrangement of multiple designs on a single sheet, enabling gangsheet optimization and increasing output while reducing setup time. It minimizes waste through optimized layouts and margins, maintains color accuracy with built-in color management, and speeds go-to-print times, delivering production efficiency in DTF for batch printing with gang sheets.

What are best practices for gangsheet optimization and batch printing with gang sheets using a DTF Gangsheet Builder?

Best practices include: prepare designs with consistent file formats and color profiles; define the sheet size, margins, bleed, and printer constraints; import designs into the builder and use auto-layout to maximize surface area; run the optimization and review the gangsheet preview for spacing and color separations; configure color management and separations for your ink system; validate before printing and save templates for recurring orders to improve repeatability; print and inspect results, then apply heat transfer printing tips such as verifying transfer film compatibility and setting the correct heat press temperature, time, and pressure to support batch printing with gang sheets.

| Section | Highlights |

|---|---|

| What is a DTF Gangsheet Builder? |

|

| Key benefits for production efficiency |

|

| Step-by-step: how to maximize production |

|

| Gangsheet optimization strategies |

|

| Real-world optimization tips |

|

| Advanced tips for scaling |

|

| Common mistakes and how to avoid them |

|

| Case study: bottlenecks to steady throughput |

|

Summary

Conclusion: A DTF Gangsheet Builder-focused approach enables a holistic upgrade to DTF production, combining layout intelligence, color management, and streamlined prepress-to-press workflows to boost throughput, reduce waste, and shorten turnaround times.