DTF Gangsheet Builder: From Design to Sheet Step-by-Step

DTF gangsheet builder reshapes how studios plan multi-design transfers, delivering a streamlined path from concept to sheet, and it helps teams reduce confusion during setup and speeding approvals. For apparel, accessories, and decor, this approach enhances DTF printing and elevates gangsheet design by organizing artwork, margins, and color blocks on a single canvas while keeping file naming consistent. A solid DTF workflow emerges as color management, asset prep, and layout come together, reducing iterations and improving production tips for consistent results across batches and different garment colors and across different product lines. By standardizing templates and export settings in your DTF design software, you gain repeatability, faster turnarounds, and easier collaboration with teammates, all while safeguarding color fidelity and print integrity. With clear visualization, previews, and automated checks, you can scale up your operations, maintain quality across every sheet, and prepare for rapid growth as demand increases across marketplaces, catalogs, and online storefronts.

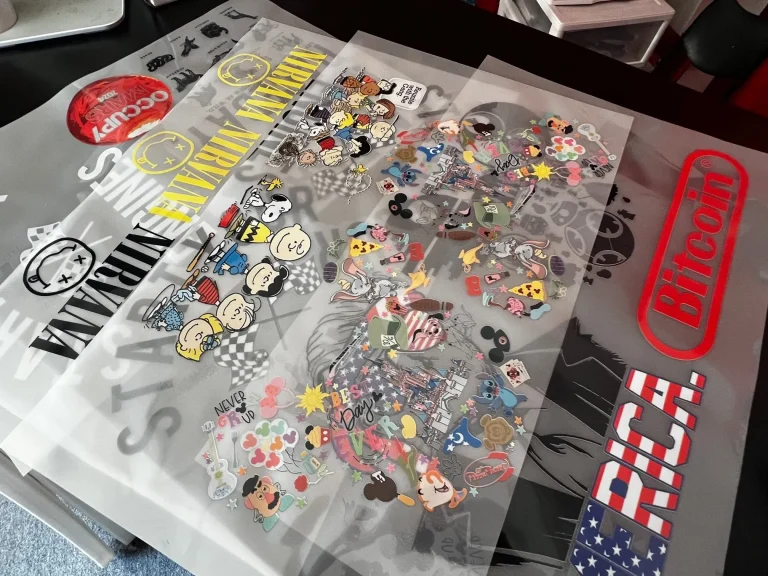

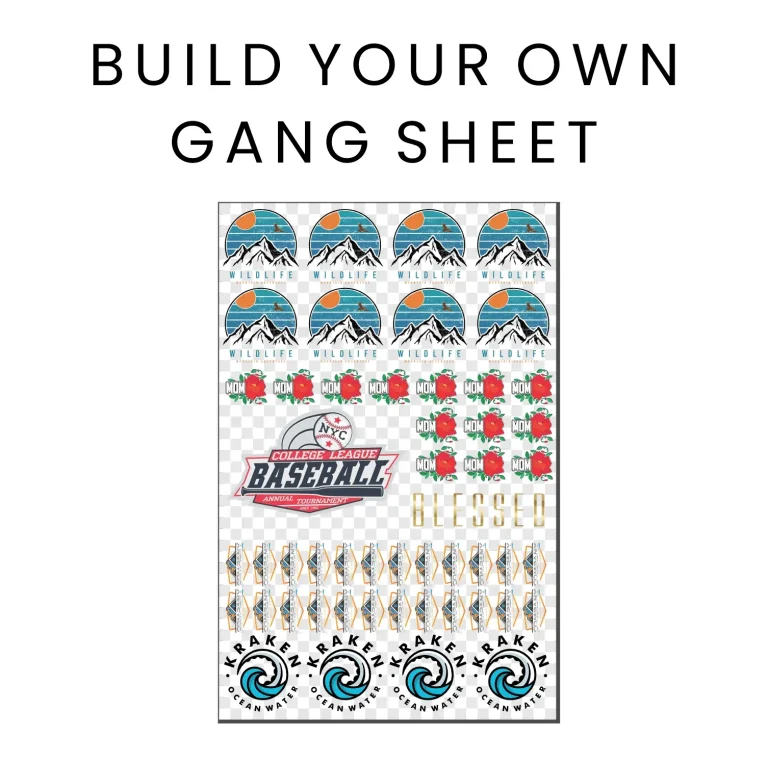

Viewed as a sheet-assembly tool, it coordinates multiple designs into a single, print-ready canvas, aligning margins, color blocks, and bleed for flawless transfers. Alternatively, a multi-design layout platform optimizes space on your transfer film while preserving each image’s color and composition. In practice, this DT sheet planner links artwork to printer settings, smoothing the handoff from design software to production and reducing waste. From setup to proofing to the final print, the core idea is a unified file-to-fabric workflow that supports color fidelity, repeatability, and scalable output. A capable layout system also enhances team collaboration—designers, prepress technicians, and operators can work together to deliver consistent results across products.

DTF Gangsheet Design: A Streamlined Workflow with the DTF Gangsheet Builder

From concept to sheet, the DTF gangsheet builder orchestrates multiple designs on a single transfer sheet, preserving color fidelity and margins while reducing setup time. This approach aligns with a practical DTF workflow for apparel, accessories, or decor, where design ideas multiply faster than you can print them. By centralizing layout, spacing, and export steps, you gain consistency across every transfer and shorten the path from idea to finished sheet.

A well-implemented gangsheet design not only cuts waste but also speeds production and lowers material costs. The builder exports a print-ready file tailored to your DTF printing setup, handling margins, bleed, and cut marks so you can focus on creative decisions. This is where DTF design software and color management come together to deliver reliable, repeatable results across the entire sheet.

DTF Production Tips: Color Management, Proofing, and Transfer for Ultimate Sheet Efficiency

To maximize throughput, gather assets early and organize them with a consistent folder structure and naming convention that reflects placement on the gangsheet and target sizes. Use vector-based formats for logos and clean rasters for artwork, ensuring all designs share a known color space (CMYK is common for DTF workflows). Embedding fonts or outlining text prevents substitutions, and a well-maintained asset library feeds a smoother DTF design software-based workflow.

Color management is a core pillar of a successful DTF production. Calibrate monitors and printers to a matching color space, and consider a printed proof on a small test sheet to validate hues and underbase opacity. When the sheet includes spot colors or metallics, map them correctly within the gangsheet builder. In the printing and transfer phase, confirm heat, speed, and curing settings, and use the preview and proofing features to verify alignment and margins before committing to a full run. This disciplined approach—often summarized as DTF production tips—helps maintain color fidelity and reduces misprints across batches.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it optimize the DTF workflow and production tips for multi-design sheets?

A DTF gangsheet builder is software or a workflow within your design suite that arranges multiple designs on a single gangsheet, preserves color fidelity, adds margins and cut marks, and exports a print-ready file for DTF printing. By coordinating layout, color management, and proofing across the entire sheet, it reduces setup time, minimizes misprints, and improves material utilization—key DTF production tips. It also helps manage white underbase and color layers to keep output consistent across designs, speeding up the DTF workflow from design to sheet.

What are essential steps when using DTF design software to create a gangsheet design for efficient production?

Start with gathering assets in consistent formats (AI, EPS, SVG for vector; PNG with transparency for raster) and set a common color space. Set up the gangsheet canvas with a grid, margins, bleed, and safe areas. Import designs, arrange with consistent orientation, and plan for white underbase and color layers. Use cloning to replicate layouts across sizes or colorways. Apply color management: select a printer-appropriate profile, calibrate monitor, and proof on a test sheet; manage any spot colors. Define transfer film paths and ensure the final sheet prints flat. Export and preview a print-ready file optimized for your DTF printing workflow. Run a physical proof and perform batch QC to catch issues before production.

| Section | Key Points | Why It Matters |

|---|---|---|

| Definition and Purpose | – DTF gangsheet builder arranges multiple designs on a single sheet; exports a print-ready file. – Reduces setup time, misprints, and material waste; improves color fidelity and margins. |

Provides a streamlined, repeatable workflow from concept to sheet, driving consistency and faster turnarounds. |

| Asset Gathering | – Collect all designs; save in vector formats (AI, EPS, SVG) for logos; PNGs with transparent background for artwork. – Use a common color space (CMYK preferred); embed fonts or outlines; create clear placement-based naming. – Maintain an organized file structure for efficient imports and batch changes. |

Ensures clean imports, accurate colors, and scalable batch editing, reducing rework. |

| Setup and Canvas | – Use a grid-based canvas and decide sheet size, margins, bleed, and safe areas. – Typical sheets hold 8–16 designs depending on size/orientation. |

Prevents clipping, optimizes space usage, and sets a predictable layout workflow. |

| Design & Layout | – Import designs, place with consistent orientation, and align white underbase and color layers to garment colors. – Adjust underbase for light/dark fabrics; clone layouts across sizes or colorways to save time. |

Promotes consistency across designs and sizes, reducing manual repositioning. |

| Color Management | – Choose a printer- and ink-compatible color profile; calibrate monitor and printer; proof on paper. – Map spot colors/metals and consider a limited palette for throughput. |

Delivers stable, predictable colors across sheets and batches. |

| White Underbase & Film Path | – Clearly indicate white underbase positions and how they interact with garment color. – Automate sequencing of white passes; plan film path to align with printer output. |

Minimizes misprints and misalignment, saving time and material. |

| Print Settings & Workflow | – Set heat, speed, ink density, curing; export a print-ready file compatible with the printer’s resolution. – Use a preview mode to verify alignment and margins; proof a single design first. |

Ensures compatibility with equipment and reduces waste through upfront verification. |

| Proofing | – Create a small physical subset for proofing; check alignment, colors, underbase opacity, and transfer look. – Use a standardized checklist and adjust layouts in the builder as needed. |

Detects issues early, minimizing full-sheet reprints. |

| Transfer & Post-Processing | – Pre-press the garment for flatness and moisture removal; test on similar fabric; ensure export formats align with transfer workflow. | Ensures a reliable transfer result and keeps file-to-finish consistent. |

| Quality Control | – Inspect each transfer for alignment, color, and cure; enable batch-level QC and annotate or tag issues for retesting. – Document learnings to improve future layouts. |

Reduces returns and builds customer trust through consistent results. |

| Troubleshooting & Best Practices | – Address color drift by re-checking profiles and reproving; fix misalignment by recalibrating and adjusting margins; reduce waste via margin tweaks. – Maintain a master asset library, standardized naming, step documentation, and regular software updates. |

Keeps production resilient, repeatable, and scalable. |

| Summary / From Design to Sheet | – A DTF gangsheet builder consolidates design, layout, color management, and print prep into one repeatable process. – Planning, organized assets, optimized layouts, and thorough proofs drive consistent, high-quality DTF output and scalability. |

Replicable, scalable workflow that moves concept to sheet efficiently. |