DTF gangsheet builder: From design to production in minutes

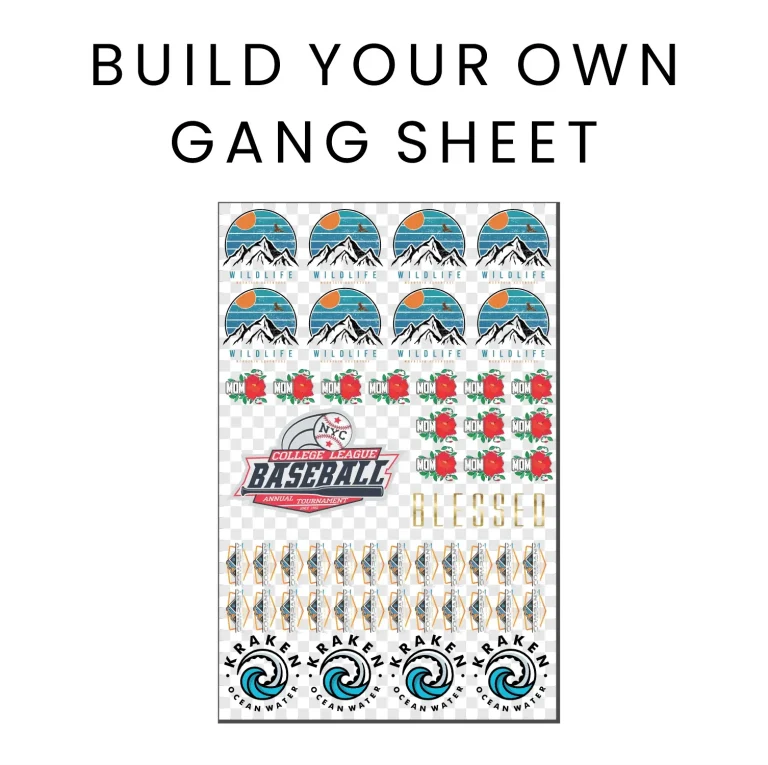

DTF gangsheet builder is a game-changing tool for printers who want to streamline transfer design, optimize sheet usage, and speed production without sacrificing accuracy. By centralizing art placement, tiling, bleed control, font and color management, and print preparation, it lets you manage multiple designs on a single sheet with precision, saving time, reducing material waste, and minimizing reprints, with built-in compliance checks and a simple, visual interface. In terms of efficiency, this solution accelerates the DTF printing workflow while helping you maintain consistent color, alignment, margins, and registration across dozens or even hundreds of transfers in a single run, with minimal interruptions. The practical benefits are clear: fewer errors, faster turnarounds, improved throughput, more predictable results that scale with your business needs, and easier onboarding for new staff. You can move from design to production in minutes while keeping quality intact, thanks to intuitive layout tools, embedded presets, and straightforward export options.

Think of it as a batch-layout studio for heat transfers that consolidates artwork, tiling, and print preparation. In industry language, you’ll encounter terms like gangsheet design tips, print-ready gangsheet, and DTF export settings as you plan layouts and color management. A related concept is DTF production in minutes, a promise of faster turnaround achieved through optimized sheet usage and repeatable processes. By framing these ideas with clear terminology, designers and shop floor technicians can collaborate more effectively while maintaining quality and scalability. The result is a flexible, web-ready workflow that supports consistent outputs across orders.

DTF gangsheet builder: From Design to Production in Minutes

A DTF gangsheet builder centralizes design, tiling, bleed, margins, color management, and export presets to streamline the entire workflow. For teams working on multi-design orders, this tool translates creative concepts into a single, print-ready gangsheet, maximizing sheet space and minimizing waste. By following proven gangsheet design tips, you can align designs on a consistent grid, keep safe margins, and prepare assets with clear layer naming so the builder can assemble each transfer accurately.

The core value is speed and accuracy: automatic tiling, snapping, rotation, and boundary guides reduce manual layout work while preserving alignment. With a robust preview and color-checking features, you can generate a print-ready gangsheet that matches your printer’s capabilities, carrier film, and heat press tolerances. The result is a faster, more reliable handoff from design to production, enabling DTF production in minutes rather than hours.

DTF export settings and print-ready gangsheet optimization

DTF export settings act as the bridge between artwork and transfer, offering presets tailored to your hardware and materials. Set a 300 dpi resolution as a baseline, apply a CMYK color profile that mirrors your printer, and embed sheet- and design-level metadata so operators know what to print and where. When these options are coordinated with a print-ready gangsheet workflow, you reduce adjustments and misprints at the heat press.

By standardizing export with metadata, color management, and transparent bleed handling, you support a consistent DTF printing workflow across batches. This approach can dramatically shorten setup times and support DTF production in minutes, especially when combined with soft proofing and embedded notes that guide operators through each transfer. Regular QA checks at export time help catch color shifts or misalignment before they reach the press.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it improve the DTF printing workflow?

A DTF gangsheet builder is a tool that arranges multiple transfer designs on a single print sheet, enabling grid-based layouts, automatic tiling, margins, and color management. By centralizing design-to-production tasks, it accelerates the DTF printing workflow, helps you generate a print-ready gangsheet quickly, standardizes export presets, and reduces errors and material waste.

How can I move from design to print-ready gangsheet in minutes using a DTF gangsheet builder?

To move from design to print-ready gangsheet in minutes, follow a compact workflow: prepare artwork at 300 dpi with clear layer names; create a gangsheet layout using grid-aligned templates with consistent borders, bleeds, and margins; apply gangsheet design tips like grouping similar sizes and avoiding fine details; manage color with your printer’s profiles and preview soft proofs; export using DTF export settings that preserve color and resolution and embed necessary metadata; perform a quick QA to confirm placement and color consistency. This approach delivers DTF production in minutes while maintaining quality.

| Topic | Key Points | Practical Takeaway |

|---|---|---|

| What is a DTF Gangsheet Builder? |

|

|

| Why Use in DTF Printing? |

|

|

| Step-by-Step Workflow Overview |

|

|

| Design Tips for Gang Sheets |

|

|

| Export Settings & Print Readiness |

|

|

| Common Pitfalls & How to Avoid |

|

|

| Real-World Example |

|

|

Summary

DTF gangsheet builder is a game changer for transfer production, enabling you to move from concept to finished gang sheets in minutes. By centralizing design, tiling, color management, and export settings into one streamlined workflow, you gain faster turnaround, consistent quality, and better control over costs. This descriptive overview shows how a DTF gangsheet builder reduces waste, standardizes layouts, and scales with demand, making it easier for printers, designers, and production teams to deliver multiple designs on a single sheet with repeatable results. Embracing this tool means simpler design to production pipelines, clearer QA checks, and the ability to handle complex orders efficiently. In short, a DTF gangsheet builder helps you turn ideas into sold products with greater speed and reliability.