DTF Gangsheet Builder: Efficient Heat Transfer Sheets Guide

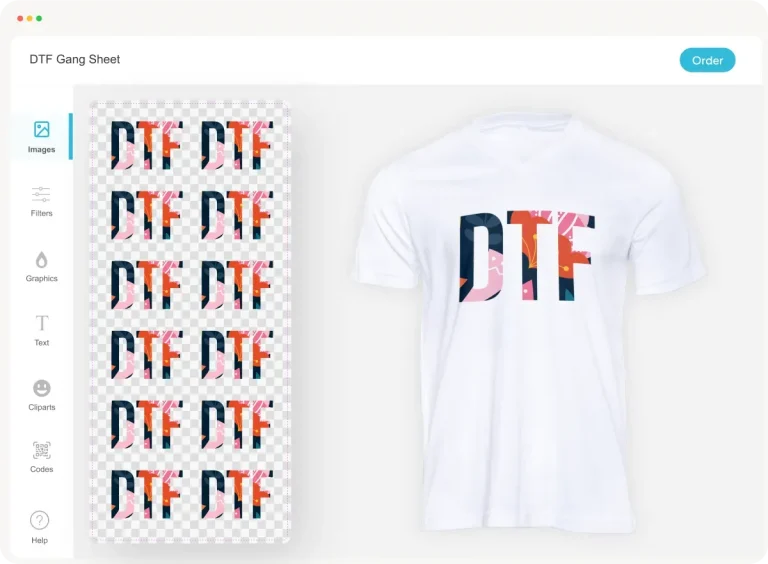

DTF Gangsheet Builder is transforming how teams and small businesses approach DTF transfer sheets and apparel printing. By arranging multiple designs on multiple heat transfer sheets, it maximizes output, reduces waste, and preserves color fidelity. This introductory guide explains what this tool does and why it matters for efficient gangsheet printing. With a focus on practical steps, it helps teams optimize DTF printer setup and routines, ensuring reliable results across different transfer substrates. Guided by DTF printing tips, users learn to balance speed, cost, and color accuracy on the same sheet.

Beyond the basics, think of this approach as a batch-layout engine that groups multiple designs into one print pass, expanding capacity without added complexity. Instead of individual jobs, you’re organizing artwork into coordinated sheets, saving time and reducing setup friction. Think in terms of templates, reusable layouts, and color-safe workflows that keep outputs consistent across garments. When paired with strong color management and compatible RIP software, this strategy supports scalable production while maintaining quality and predictability.

DTF Gangsheet Builder: Maximize DTF Transfer Sheets with Efficient Gangsheet Printing

Using a DTF Gangsheet Builder, you can arrange multiple designs on a single DTF transfer sheet before printing. This capability enables gangsheet printing that maximizes each heat transfer sheet, reduces material waste, and accelerates production without sacrificing color fidelity. For teams scaling operations, the real bottleneck often becomes sheet efficiency, not the printer or ink, and a well-designed gangsheet workflow helps address that head-on while keeping prints vibrant and soft to the hand on textiles.

Core features to prioritize include grid and alignment tools, bleed and margin controls, a template library, and robust color management with ICC profiles and soft proofing. Batch workflow support and RIP-integrated printer compatibility ensure you can queue designs and export print-ready files in one go, preserving color integrity across all designs on the DTF transfer sheet. In practical terms, a reliable DTF Gangsheet Builder reduces misalignment, cut waste, and setup time, turning a potentially complex setup into a repeatable, scalable process for heat transfer sheets.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve gangsheet printing on DTF transfer sheets?

The DTF Gangsheet Builder is a tool that lets you organize multiple designs on a single DTF transfer sheet before printing. It optimizes grid layouts, margins, and bleed to maximize sheet usage, reduce waste, and speed up production. It also standardizes color management across designs, supports templates for common garments, and enables batch prints with DTF printer setup and RIP integration. To use it, define your sheet size, place designs with precise alignment, embed color profiles, preview for spacing, and export a print-ready file for a single run.

Which features in a DTF Gangsheet Builder support efficient heat transfer sheet production and DTF printing tips?

Key features include grid/alignment, bleed and margin controls, template library, ICC color management, batch workflow, printer compatibility with RIPs, and live preview/validation. Practical steps: 1) prepare artwork and color profiles (DTF printing tips) 2) define sheet size and margins 3) import/place designs 4) add bleed, safe areas, and crop marks 5) preview, validate, and export 6) print, cure, and transfer. This workflow improves DTF printer setup, reduces misprints, and scales production while preserving color fidelity on heat transfer sheets.

| Aspect | Key Points | Benefits / Why It Matters |

|---|---|---|

| What is a DTF Gangsheet Builder? |

|

Increases sheet utilization, lowers per-item costs, speeds up production, and maintains vivid, durable transfers. |

| Why it matters for efficient heat transfer sheets? |

|

Boosts production throughput, lowers costs, and improves consistency across garments like T‑shirts, hoodies, and bags. |

| Core components of a strong DTF gangsheet workflow |

|

Creates a repeatable, scalable process with fewer alignment errors and more predictable results. |

| Core features to look for in a DTF gangsheet builder |

|

Improves accuracy, consistency, and efficiency; reduces misprints and rework. |

| Step-by-step guide: building efficient heat transfer sheets |

|

Provides a practical, repeatable workflow to maximize sheet usage and ensure print quality. |

| Practical tips for better gangsheet efficiency |

|

Keeps outputs uniform, saves time, and reduces rework. |

| Common issues and how to address them |

|

Proactive fixes reduce waste and downtime and improve reliability. |

| Advanced strategies for scaling with a DTF Gangsheet Builder |

|

Supports scalable production while preserving quality, consistency, and throughput. |