DTF GangSheet Builder: Design to Output for Multi-Print

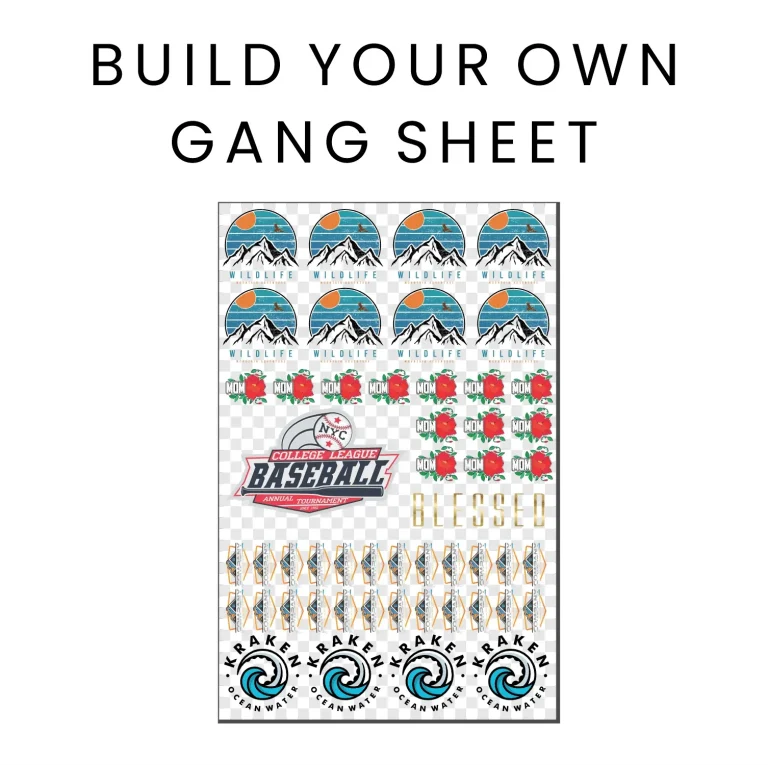

DTF GangSheet Builder is changing the game in digital textile printing by turning scattered artwork into a single, print-ready framework that designers can trust. By centralizing this workflow, the tool simplifies gang sheet design and reduces the time spent arranging multiple designs for mass runs. It translates individual designs into a cohesive set of gang sheets optimized for multi-print sheets, elevating the DTF printing workflow from concept to substrate. With built-in margins, gutters, color-preserving previews, and RIP-compatible outputs, it helps preserve color fidelity and keep production on track. In this guide, you’ll learn how to move from design to output with confidence, how the builder streamlines planning with gang-sheets in mind, and how to maximize throughput without sacrificing quality.

Think of the tool as a centralized canvas or shared print sheet that groups several designs for efficient production. Viewed through an LSI lens, this automation acts as a multi-design layout engine, enabling bulk-ready sheets that maintain color relationships across repeats. From a manufacturing perspective, rapid setup, reduced waste, and consistent results emerge when you treat designs as a collective file rather than individual jobs. By embracing alternatives like shared canvases, bulk-layout workflows, and production-ready gang-sheets, you align creative decisions with the realities of printing. This Latent Semantic Indexing-inspired framing helps you see how the same capability maps to different terms while still delivering reliable, repeatable outcomes.

DTF GangSheet Builder: Accelerating multi-print sheets with precise gang sheet design

In the DTF printing workflow, gang sheets unlock throughput by consolidating multiple designs onto a single printable canvas. The DTF GangSheet Builder centralizes asset placement, margins, gutters, and color-proofing, delivering a single print-ready file that preserves color relationships from screen to substrate. By handling grid layout, bleed allowances, and proof previews, it cuts setup time dramatically and enables rapid iterations during reviews and color proofs.

Design with gang sheets in mind to maximize throughput without compromising quality. Consider your printer bed size, orientation (landscape vs. portrait), and safe zones, and use standardized color palettes to minimize ink changes and color drift. The builder’s Lightroom-like previews and embedded color profiles help ensure consistent results across multi-print sheets and support DTF transfer optimization, making it easier to translate digital designs into accurate garment prints.

Best practices include creating standardized templates for common product lines (e.g., T-shirts, hoodies, bags) and validating with digital textile printing tips and proofs before production. By standardizing margins, bleeds, and color management, you reduce waste and speed up production, turning complex gang-sheet layouts into repeatable, scalable workflows.

DTF printing workflow and gang sheet design: optimizing color consistency across multi-print sheets

A robust DTF printing workflow hinges on consistent color management and precise gang sheet design. Use ICC profiles and calibrated color spaces to align on substrate, and employ soft-proofing to anticipate how hues will render on fabric. When multiple designs share a single sheet, this approach helps maintain color fidelity across every design in the batch, which is essential for multi-print sheets and reduced color drift during DTF transfer optimization.

To maximize results, embed fonts, convert text to outlines, and keep artwork within printer-safe margins. The DTF GangSheet Builder outputs print-ready PDFs or TIFFs with embedded color profiles, streamlining the RIP/printer workflow and enabling controlled test prints that minimize waste. Consistent gutters and margins further support color consistency, reducing ink bleed and misalignment across designs.

A practical example shows six T-shirt prints arranged on a single sheet using a grid and standardized bleed. This demonstrates how disciplined gang-sheet design in the DTF printing workflow can shorten setup time, ensure uniform color across all designs, and accelerate delivery to customers while maintaining high print quality.

Frequently Asked Questions

How does the DTF GangSheet Builder improve the DTF printing workflow for multi-print sheets?

The DTF GangSheet Builder centralizes layout, auto-places designs on a grid, enforces consistent margins, bleeds, and gutters, preserves color relationships with embedded ICC profiles, and exports a single print-ready file compatible with your RIP. This streamlines the DTF printing workflow for multi-print sheets, reducing setup time from minutes per design to seconds per sheet, minimizes misalignment, and improves color consistency across the batch.

What design considerations and best practices should I follow when using the DTF GangSheet Builder for gang sheet design?

Focus on standardized templates, defined sheet size, and a clear grid (columns and rows). Plan margins, bleeds, and gutters to prevent ink bleed and edge cropping, and embed ICC profiles for reliable color. Use the builder’s proofs and previews to validate colors, then export a single print-ready file. Group similar colors to optimize color separation and ink changes, and apply digital textile printing tips and DTF transfer optimization ideas to maximize efficiency and consistency across multi-print sheets.

| Topic | Key Points | Notes |

|---|---|---|

| Introduction | DTF GangSheet Builder centralizes the workflow, converts multiple designs into gang sheets, optimizes multi-print runs, and helps maintain color fidelity to meet deadlines. | Focus on moving from design to output with confidence; emphasizes efficiency and consistency in multi-design production. |

| What is the DTF GangSheet Builder? | Specialized software to create gang sheets by placing multiple designs on a shared canvas; handles layout, margins, bleeds, gutters, and color-preserving previews; outputs a single print-ready file; integrates with common RIPs and printer profiles. | Bed-size aware; generates Lightroom-like previews and proofs to ensure colors stay true from screen to substrate. |

| Why use a gang sheet for multi-print runs? | Reduces downtime, improves color consistency, and speeds setup; minimizes material waste and misprints when running multiple designs or colorways on one sheet. | Single color profiles applied across all designs on the sheet; facilitates faster iterations and lower production costs. |

| Design considerations for effective gang sheets | Canvas size, orientation (landscape or portrait), margins and bleeds, gutters, and color management; ensure critical elements are kept away from edges. | Plan around printer bed dimensions and safe zones to avoid trimming issues. |

| Workflow: from design to output with the DTF GangSheet Builder | 1) Prepare assets (embed fonts, ensure CMYK). 2) Define gang sheet size, columns, rows, and rotation. 3) Place designs (auto or manual). 4) Apply margins, bleeds, and gutters. 5) Color-proof and validate. 6) Output a single print-ready file (PDF/TIFF) with embedded profiles. 7) Send to RIP/printer and run a controlled test. 8) Post-production checks for alignment and color accuracy. | Step-by-step to ensure consistent output across runs. |

| Best practices for maximizing results with the DTF GangSheet Builder | – Create standardized templates for common product lines. – Use consistent color palettes across all designs. – Plan for the full run to optimize layout density. – Manage print order to minimize color changes. – Validate with proofs and compare digital vs. physical prints. | Templates and color discipline reduce setup time and waste. |

| Common pitfalls to avoid in gang-sheet design | Overcrowding the sheet, inconsistent margins, underestimating gutter width, and neglecting color management can cause misalignment, edge quality issues, and color drift. | Enforce safe zones, consistent margins, and unified color profiles; maintain human oversight during proofing. |

| A practical case: designing a set of six t-shirt prints on a single gang sheet | Six designs placed on a 4-column by 2-row grid with 0.125-inch bleed; automatic placement; preview mode checked; export a single PDF for RIP; one-pass production. | Demonstrates efficiency gains and consistent color across all designs in a batch. |