DTF GangSheet Builder: Common Mistakes to Avoid in 2026

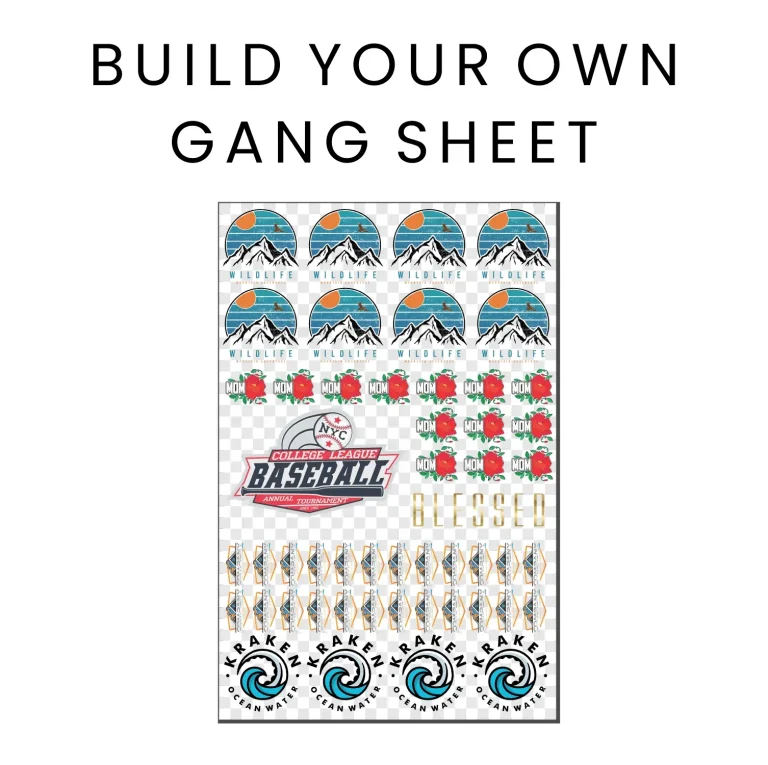

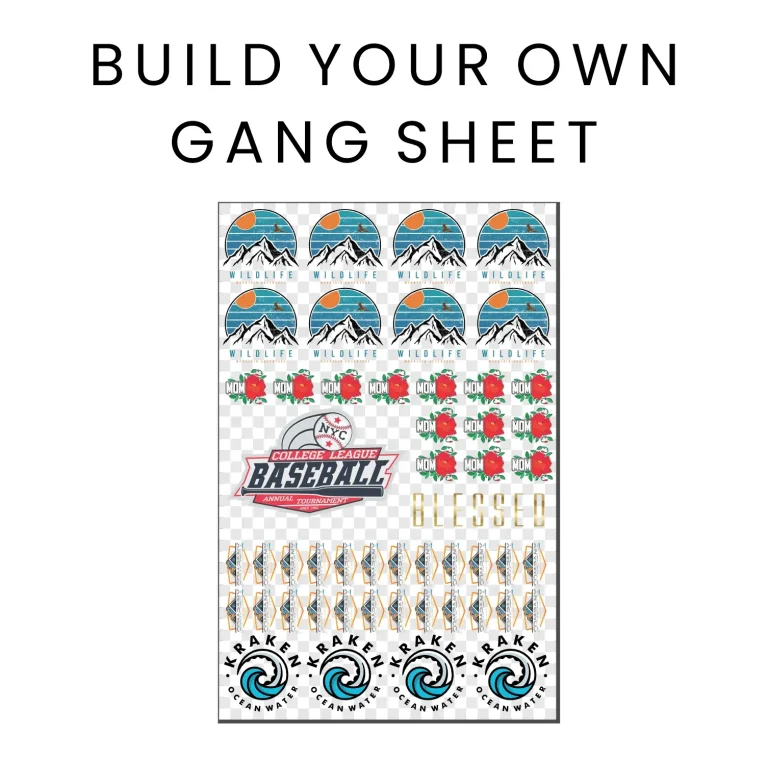

DTF GangSheet Builder unlocks a streamlined workflow that lets you combine multiple designs on a single transfer sheet, boosting output without sacrificing quality. When you deploy this tool effectively, you can maximize production velocity, tighten color control, and reduce waste, which is why many printers rely on practical tips to stay efficient. However, even seasoned operators encounter issues that undermine accuracy, so understanding margins, color calibration, and reliable prepress checks matters. This introductory guide highlights practical strategies to optimize your gang sheet layouts and follows gang sheet layout best practices for reliable results. By applying these ideas, you can produce vibrant, durable transfers across designs while keeping material use and turnaround times under control.

From a practical perspective, this tool functions as a multi-design transfer planner, grouping several artworks onto one printable sheet to boost throughput. In LS I terms, the process reads like design consolidation, where margins, bleed, color blocks, and timing are orchestrated across designs to minimize waste. Think of it as a workflow that champions organized grids and consistent spacing, applying design-and-layout principles to maintain legibility and alignment. To keep production smooth, integrate DTF printer setup for gang sheets and DTF printing troubleshooting into your prepress and press planning. By reframing the task with these terms, you address related concerns such as color management, type-to-fabric alignment, and adhesive coverage, while remaining mindful of overall efficiency.

DTF GangSheet Builder: Maximize Production with Smart Gang Sheet Layout

The DTF GangSheet Builder helps you maximize throughput by combining multiple designs on a single transfer sheet. This approach aligns with gang sheet layout best practices, ensuring consistent margins, safe zones, and balanced color distribution across the sheet. When used correctly, it streamlines the workflow by integrating design software, a compatible printer, and the gang sheet design rules, reducing idle time and waste while preserving color integrity.

To implement this effectively, start with a clear plan for each sheet—decide the number of designs, orientation, and spacing—and then test the setup with a scrap sheet. Maintain a library of approved layouts to speed decision-making and ensure consistency across orders. Regularly verify DPI, margins, and bleed, and calibrate your monitor and printer to keep color aligned from design to final transfer, leveraging DTF gang sheet printer tips to stay productive and minimize DTF printing troubleshooting needs.

Common Pitfalls and Practical Fixes for DTF Printing: From Prepress to Press

Skipping prepress checks is one of the most damaging DTF transfer mistakes. Always flatten artwork, confirm the correct color profile, and use high-resolution images before printing. Skipping this step often leads to fuzzy edges, color shifts, and banding on the final transfer. The fix is a small test print on your DTF printer to confirm alignment and color, plus verifying sheet dimensions with your gang sheet builder—this is foundational to reducing DTF printing troubleshooting issues.

Other frequent missteps include incorrect margins and bleed, inconsistent color management, and rushed print quality settings. Ensure margins are sufficient to prevent edge trimming, maintain safe zones between designs, and calibrate color with a known profile. For heat press timings and powder application, follow documented guidelines and perform dry runs to prevent adhesion problems. By addressing these common DTF transfer mistakes with established practices, you minimize reprints and improve overall sheet integrity, staying aligned with DTF printing troubleshooting recommendations.

Frequently Asked Questions

How does the DTF GangSheet Builder reduce DTF transfer mistakes and what are some DTF gang sheet printer tips to get started?

The DTF GangSheet Builder streamlines placing multiple designs onto a single transfer sheet, enforcing gang sheet design rules to improve alignment, color management, and throughput. This helps prevent common DTF transfer mistakes such as misregistration, color shifts, and uneven adhesive coverage. To get started, apply practical DTF gang sheet printer tips: verify artwork is flattened and in the correct color space, set proper margins and bleed, calibrate your monitor and printer, run a small test print to confirm alignment, and confirm sheet dimensions within the DTF GangSheet Builder. Maintain a consistent DTF printer setup for gang sheets (DPI, heat press settings, and powder application) and keep your workflow organized to reduce reprints.

What are the gang sheet layout best practices when using the DTF GangSheet Builder to maximize throughput and color accuracy?

Follow gang sheet layout best practices to optimize design placement and minimize waste: plan the number and orientation of designs, use a grid with clear margins and safe zones, and test the setup with a scrap sheet before production. The DTF GangSheet Builder helps manage spacing and alignment, supporting consistent color management across the sheet. Build a library of approved layouts, calibrate color per batch, and document adjustments. If issues occur, consult DTF printing troubleshooting steps for misregistration, heat press pressure, and powder distribution to prevent DTF transfer mistakes.

| Topic | Key Points |

|---|---|

| Understanding the gang sheet concept |

|

| Common Mistakes to Avoid |

|

| Best Practices for Gang Sheet Layout |

|

| Color management and calibration strategies |

|

| DTF printing tips and troubleshooting |

|

| Workflow optimization and batch processing |

|

| Quality control and final checks |

|

| Conclusion |

|

Summary

DTF GangSheet Builder enables a streamlined workflow to maximize production efficiency by combining multiple designs on a single transfer sheet, helping shops increase output per press run without sacrificing color accuracy or durability. Understanding the gang sheet concept and avoiding common mistakes—such as skipping prepress checks, mismanaging margins, or neglecting color calibration—sets a strong foundation for reliable, vibrant transfers across designs. By applying best practices for layout, color management, tooling, and quality control, operators can reduce waste, shorten turnaround times, and improve consistency across orders. Embrace batch processing, thorough documentation, and ongoing optimization to fully leverage the DTF GangSheet Builder and scale production with confidence.