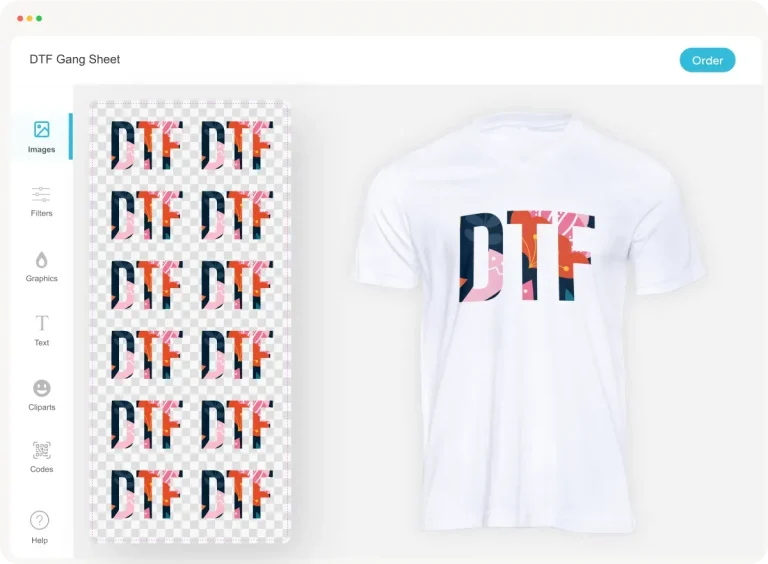

DTF Gangsheet Builder: Color-Rich Transfers for Apparel

DTF gangsheet builder reshapes the journey from artwork to wearable print by letting you cluster multiple designs onto a single transfer sheet. This approach supports color-rich transfers while keeping the DTF printing workflow streamlined and predictable. By focusing on efficient gang sheet design, you can reduce setup time, material waste, and color variability across orders. The tool doesn’t replace creativity; it coordinates how art translates into vibrant, durable prints on fabric, preserving design for DTF transfers. For brands aiming to scale, this technology offers clear gains in throughput, consistency, and profitability.

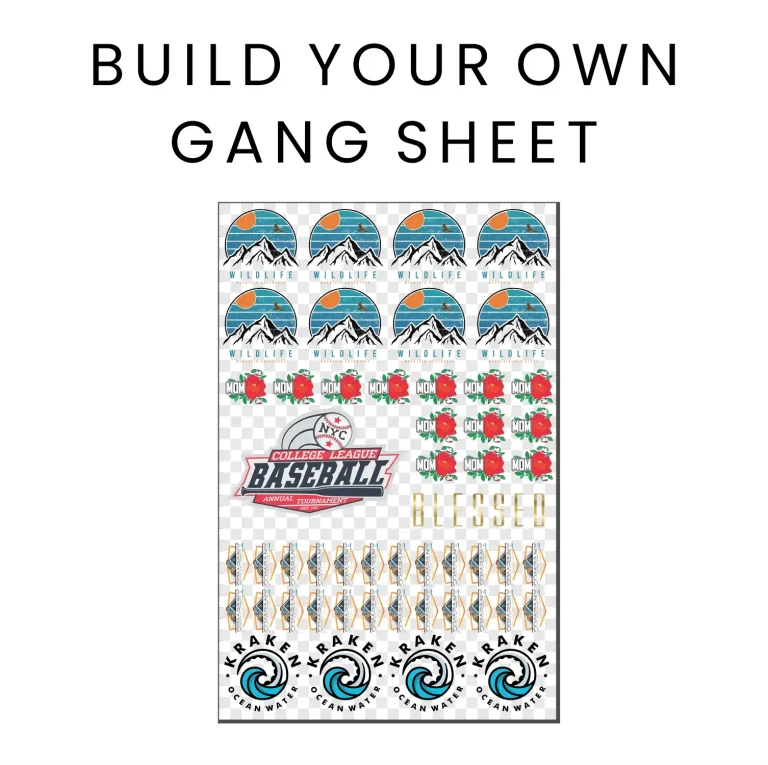

Think of a multi-design layout platform that packages several art assets into one transfer sheet, optimizing space and ink use. These tools support a color-rich transfers strategy by harmonizing palettes, proofs, and print parameters across designs. From a production standpoint, this gang-sheet planning streamlines the DTF printing workflow by reducing setup changes and improving consistency across fabrics. Framing the process as design for DTF transfers helps teams iterate, verify color accuracy, and scale output without sacrificing quality. Ultimately, the focus is on efficient sheet layouts, reliable color management, and robust results for apparel lines.

DTF Gangsheet Builder: Mastering Color-Rich Transfers with Smart Gang Sheet Design

Using a DTF gangsheet builder to plan multiple designs on one transfer sheet unlocks a disciplined approach to color-rich transfers. By centralizing layout decisions, you maximize space on each sheet while preserving color accuracy, aligning with the broader DTF printing workflow. This is where gang sheet design becomes strategic: you map each artwork’s position, orientation, and bleed to keep prints crisp from edge to edge.

With a focus on color management, the designer can apply a single color profile and consistent ICC settings to every design on the gang sheet. This reduces color drift, preserves vibrant hues, and minimizes ink waste. The result is a scalable method to produce a catalog of color-rich transfers that maintain brand fidelity across garments while cutting production costs per unit.

Design for DTF Transfers and a Streamlined DTF Printing Workflow

Designing for DTF transfers means thinking about how each design renders on fabric and how they fit together on a single sheet. Build a shared palette, plan gradients, and position elements to exploit the heat press while keeping edges sharp. By considering fabric types and transfer densities early, you create a design for DTF transfers mindset that yields consistent results across a range of garments.

Integrate the gang-sheet approach into the DTF printing workflow with prepared test swatches, color proofs, and standardized post-processing steps. Calibrate printers and media regularly, account for fabric variability, and document every configuration change. When the workflow is streamlined, color-rich transfers become repeatable, enabling faster turnaround, better quality control, and happier customers.

Frequently Asked Questions

How does a DTF gangsheet builder improve the DTF printing workflow and color-rich transfers?

A DTF gangsheet builder lets you arrange multiple designs on a single transfer sheet, applying a shared color profile and consistent ICC settings across all designs. This streamlines the DTF printing workflow by reducing setup changes, speeding production, and improving color-rich transfers with uniform gradients and reduced color drift. It also minimizes waste and misregistration by printing in a single run. The tool supports efficient gang sheet design by centralizing layout decisions while preserving artwork quality.

What should you consider when designing a gang sheet with a DTF gangsheet builder?

Define the output size and margins, prepare high-resolution artwork with transparent backgrounds where needed, and build a shared color palette to maintain color harmony. Plan the layout for optimal heat transfer, include test swatches and registration marks, and export files in consistent formats to ensure a smooth DTF printing workflow. This approach aligns with design for DTF transfers and gang sheet design, promoting color fidelity, repeatable results, and scalable production.

| Topic / Key Point | Summary |

|---|---|

| What is a DTF gangsheet builder? | A specialized tool to arrange multiple artwork files on one transfer sheet, enabling gang-sheet printing to save time, reduce waste, and maintain color consistency. |

| Key benefits of a gangsheet builder | Improves efficiency and throughput; ensures consistent color management; reduces material costs; simplifies post-processing by standardizing steps across the batch. |

| Color-rich transfers with gangsheet design | Optimizes color utilization, maintains uniform gradients and halftones, reduces misregistration risk, and streamlines color proofs. |

| Designing for DTF transfers: high-level steps | Define output size and margins, ensure appropriate resolution, use a shared color palette, position designs for reliable heat transfer, include test swatches and registration marks. |

| Practical workflow tips | Export designs in consistent formats, calibrate color with proofs, account for fabric variability, optimize ink usage, prep garments/platen, and document processes. |

| Troubleshooting common issues | Watch for color drift, registration errors, uneven transfers, and ink bleed on dark fabrics; use gangsheet proofs and test cuts to mitigate. |

Summary

DTF gangsheet builder is a transformative tool for turning color-rich designs into scalable, production-ready transfers. This approach integrates smoothly into the DTF printing workflow by grouping multiple artworks on a single sheet, improving color consistency, reducing waste, and speeding up production. By emphasizing gang-sheet design and careful planning of output size, color palettes, and alignment marks, you can maximize yield and profitability while preserving image fidelity across garments. Designers and printers can leverage this workflow to expand catalogs, meet multi-design orders, and deliver vivid, durable transfers on a range of fabrics.