DTF GangSheet Builder: Choosing the Right Tool for Studio

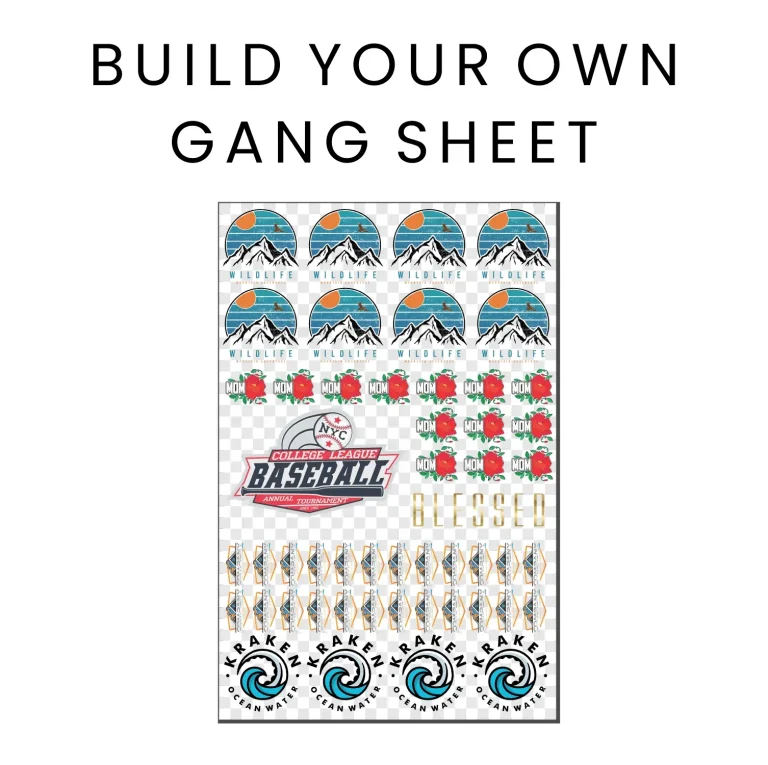

DTF GangSheet Builder is transforming how studios plan transfers, delivering vibrant colors, tight alignment, and faster turnarounds. By laying out multiple designs on a single print sheet, it maximizes material usage and reduces setup time. As part of a broader DTF workflow optimization, this kind of tool supports efficient DTF batch printing and consistent color management. A strong builder offers templates, precise tiling, bleed settings, margins, and alignment marks, and it should integrate with your printer and RIP. When evaluating options, choosing the right DTF GangSheet Builder helps ensure cost predictability and positions your shop with the best DTF printer software.

From a terminology perspective, a gang-sheet tool is a smart layout engine that groups multiple designs on one film to save material and time. This approach, often described as DTF gang sheet software or gang sheet layout software, connects artwork to production with templates, tiling, and alignment controls. By focusing on automation and scalability, it enables batch printing of transfers with consistent margins and color, supporting DTF workflow optimization. The result is faster quotes, reduced waste, and easier integration with your printer, RIP, and order management, enabling efficient DTF batch printing.

DTF GangSheet Builder: Maximizing Print Efficiency and Material Use

In a growing studio, a DTF GangSheet Builder helps transform multiple designs into efficient gang sheets, letting you pack more transfers per print and reduce wasted film. By automatically tiling designs, aligning margins, and applying bleed settings, this tool lowers setup time and speeds quoting. It ties directly into DTF gang sheet software ecosystems and supports DTF batch printing workflows, enabling data-driven decisions about yields and costs.

A robust solution should integrate with your printer, inks, and RIP, while offering template libraries and precise tiling. With edge-to-edge packing and rotation options to minimize waste, the builder supports DTF batch printing and DTF workflow optimization, helping studios scale without escalating labor. When paired with color management and the best DTF printer software, you can simulate outputs before printing to guard against surprises.

How to Choose and Implement the Right DTF Layout Solution for Your Studio

To choose the right tool, start by mapping your common job sizes and designs to the printer and film you use. Verify that the DTF gang sheet software you consider supports your file formats (PNG, TIFF, SVG, PDF) and preserves transparency, and that it can integrate with your RIP if you use one. Look for a gang sheet layout software that offers edge-to-edge packing, reliable tiling, and a straightforward trial period to confirm real-world benefits.

Beyond features, assess ROI via setup time reductions, waste, and speed to quote. Favor solutions with templates for tees, hoodies, and sleeves, and with automation for naming and indexing to streamline the RIP prep. A strong DTF layout solution should integrate with your order management and provide color management presets and soft-proofing so you can verify color fidelity before printing, supporting DTF workflow optimization and efficient DTF batch printing.

Frequently Asked Questions

What features should I look for in a DTF GangSheet Builder to optimize DTF workflow optimization and reduce production time?

A strong DTF GangSheet Builder should offer robust layout and tiling to place multiple designs on a single sheet with automatic spacing and easy reorganization; precise bleed, margins, and alignment to prevent artifacts and ensure clean cuts; solid color management with built‑in ICC profiles and soft‑proofing to maintain print fidelity; broad file compatibility with common formats (PNG, TIFF, SVG, PDF) and templates for standard item sizes; automation for naming and prepping print files for the RIP, plus scalable performance and clear licensing and support terms.

How can a DTF gang sheet software like the DTF GangSheet Builder improve DTF batch printing efficiency and reduce costs?

By enabling gang‑sheet layouts that maximize transfers per sheet and automate repetitive steps, the DTF gang sheet software reduces setup time and speeds multiple‑design jobs; it minimizes material waste through precise tiling, margins, and bleed; it strengthens color consistency with ICC profiles and prebuilt presets; it integrates with your printer, RIP, and order workflow to streamline production and quoting, delivering a lower cost per transfer as your batch printing scales.

| Aspect | Key Points | Impact / Notes |

|---|---|---|

| What is a DTF GangSheet Builder? | Creates gang sheets by laying out multiple designs on one film; maximizes transfers per run; preserves color accuracy and alignment; integrates with your printer, inks, RIP (if used), and design workflow. | Enables a smooth path from artwork to transfers with minimal friction. |

| Why this matters for your studio | Affects yield and cost per transfer; reduces setup time; aids accurate pricing; supports scalable production. | Small shops gain a competitive edge; larger studios scale without proportional labor increases. |

| Efficient layout and tiling | Place multiple designs on a single sheet with automatic/manual tiling, spacing, edge-to-edge packing, rotation, and quick reorganization. | Reduces waste and speeds up the prep phase. Related: DTF batch printing. |

| Precise bleed, margins, and alignment | Consistent margins and bleed to prevent edge color artifacts; alignment marks and reference grids for accuracy across runs. | Improves trim accuracy and order-to-order consistency. |

| Color management and print fidelity | Support for color profiles, ICC presets, and print simulation before running batches. | Predictable color output when paired with printer and RIP; better visual quality. |

| File compatibility and input formats | Ingest designs from Illustrator, Photoshop, PNG, TIFF, SVG, PDF; preserves transparency and layer information when needed. | Smooth workflow with minimal conversion steps. |

| Template libraries and presets | Ready-made templates for item sizes; save and reuse personal templates for speed. | Faster setup and consistent layouts across jobs. |

| Automation and workflow integration | Automate naming/indexing/prepping for RIP; integrate with order management, inventory, scheduling; support via standard file formats. | Reduces manual tasks and supports end-to-end production flow. |

| Scalability and performance | Handles larger files and more designs per sheet; batch processing; fast layout rendering; efficient memory use. | Keeps pace with growing studios without sacrificing speed. |

| Platform compatibility and updates | Check OS compatibility, printer model, film, ink; assess vendor update cadence and support. | Ensures long-term usability and support. |

| Licensing and cost structure | One-time license vs subscription; update policies; potential modules for advanced features. | Budget planning for long-term value. |

| Support and community | Responsive support, clear documentation, active user community for troubleshooting. | Faster problem resolution and knowledge sharing. |

| Choosing the right fit for printer and workflow | Ensure compatibility with your printer, film, and inks; test with common job types; request a trial when possible. | Minimizes mismatch risk and validates real-world performance. |

| Practical tips for getting started | Pilot projects with 3-5 designs; create templates; standardize margins/bleed; build a color management plan; document workflow; track outcomes. | Jumpstarts ROI and ensures repeatable gains. |

| DTF gang sheet software vs traditional methods | Dedicated gang-sheet tools reduce manual steps and human errors; faster throughput; potential ROI from reduced waste and quotes. | Highlight the efficiency gains over generic layouts. |

| Real-world outcomes you can expect | Reduced setup time; less material waste; improved color consistency; higher throughput; clear documentation and scalable processes. | Leads to faster quotes, happier customers, and growth. |

Summary

Conclusion: Choosing the right DTF GangSheet Builder is a strategic decision that can influence your studio’s efficiency, profitability, and ability to scale. By prioritizing layout efficiency, precise bleed and alignment, color management, compatibility with your printer and workflow, and solid vendor support, you set the foundation for consistent, high-quality transfers and happier customers. Take advantage of trials, test with your most common job types, and build templates that reflect your real-world needs. With the right builder in place, you’ll unlock faster turnaround times, less waste, and a smoother path from design to finished product.