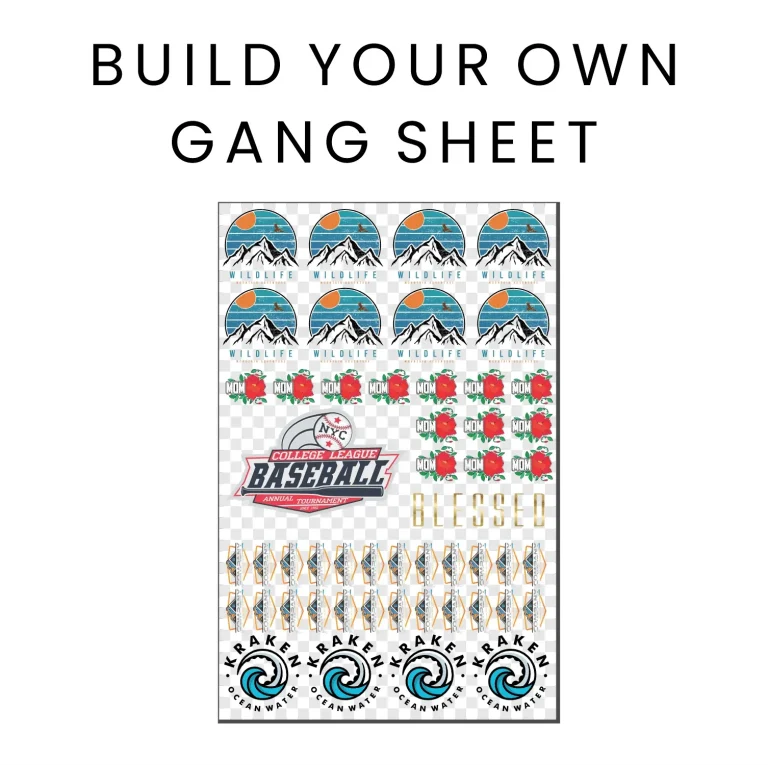

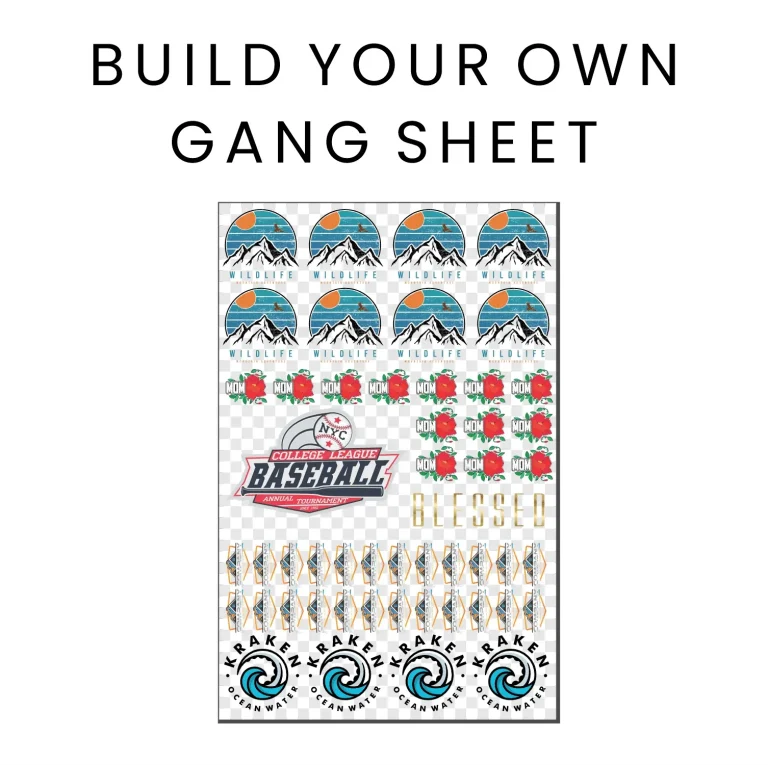

DTF gangsheet builder boosts production efficiency

DTF gangsheet builder is transforming on-demand apparel production by automating layout planning for multiple designs. It enhances workflow by efficiently packing designs within film dimensions to minimize waste. This streamlined approach reduces setup time and lowers waste across jobs. Color management stays consistent with print-ready files that speed prepress. Industry feedback highlights gains in productivity and cost efficiency from adopting this approach.

Viewed through the lens of Latent Semantic Indexing, the idea emerges as automated prepress for heat-transfer films, focusing on efficient tiling and sheet planning. LSI-inspired terms such as automated prepress, sheet tiling, and film-layout optimization point to the same core capability. In practice, the framing helps teams improve DTF production efficiency by increasing throughput and reducing waste.

DTF gangsheet builder: Accelerating the DTF printing workflow and boosting production efficiency

A DTF gangsheet builder automates the layout of multiple designs on a single film, factoring in available film width and length, required bleed, margins, color counts, hotspot areas, and printing order. This optimization minimizes gaps and alignment risks, streamlining the DTF printing workflow and delivering measurable gains in production efficiency.

In the case study, a mid-sized shop began with a six-week discovery and pilot, then integrated the gangsheet builder with the RIP and prepress workflow. The result was substantial: setup time dropped by roughly 38–42%, daily throughput increased by about 25–30%, and material waste decreased by 15–20%. These improvements illustrate the impact of gangsheet optimization on overall DTF production efficiency and the potential ROI within six to nine months.

Insights from the DTF case study: gangsheet optimization for scalable production

The case study demonstrates how gangsheet optimization extends beyond prepress—stabilizing the entire DTF printing workflow from file preparation through curing and finishing. By maintaining consistent color separations and margins across designs on a single sheet, shops achieve better color management and reduced misprints, leading to higher DTF production efficiency.

To replicate the success, teams should run a focused pilot, define clear success metrics (setups, throughput, and waste reduction), ensure RIP and printer compatibility, and invest in operator training. Tracking ROI over six to nine months and planning for scale will help organizations realize sustained improvements in the DTF case study outcomes and maintain a competitive edge in the broader DTF printing workflow.

Frequently Asked Questions

How does a DTF gangsheet builder impact the DTF printing workflow and production efficiency?

A DTF gangsheet builder automatically packs multiple designs on one gangsheet, optimizing bleed, margins, color separations, and print order. This streamlines the DTF printing workflow by reducing manual layout, improving color alignment, and generating print-ready files via the RIP, leading to faster setup, lower waste, and higher production efficiency. In case studies, typical gains include a 38–42% reduction in setup time, a 25–30% increase in daily throughput, and 15–20% waste reduction.

What can a DTF case study teach you about gangsheet optimization and implementation?

A DTF case study highlights practical steps for gangsheet optimization: ensure compatibility with your RIP and printer fleet, define measurable success metrics (setup time, throughput, waste), run a pilot with representative orders, train users to interpret generated gang sheets, and plan for scalable growth. Benefits observed include smoother prepress workflows, improved color consistency across designs on a sheet, reduced changeover time, and enhanced DTF production efficiency.

| Aspect | Key Points |

|---|---|

| Introduction | DTF printing is popular for on-demand apparel; a gangsheet builder automates multi-design layout to optimize film usage, reduce waste, and speed production. |

| Baseline challenges | Manual layouts caused suboptimal sheet usage, inconsistent margins and bleed, long setup times, and color management issues across designs. |

| What it does | Automatically generates efficient gang sheets considering film size, bleed, margins, color counts, hotspot areas, and print order; outputs print-ready files; reduces waste and streamlines finishing. |

| Implementation and setup | Six-week discovery and pilot; integrates with RIP and prepress workflows; training on interpreting results and verifying color integrity. |

| Key features | Automatic layout optimization; Bleed and margin control; Color management compatibility; Job queue and naming; RIP integration; Changeover facilitation. |

| Outcomes | Setup time reduced roughly 38-42%; Throughput increased about 25-30%; Waste per batch declined 15-20%; Color consistency improved; ROI/payback typically 6-9 months. |

| Human impact | Operators reported lower cognitive load, more time for print quality checks, and greater adherence to timelines; training focused on interpreting layouts and verifying output. |

| Broader workflow | Prepress gains lead to more predictable downstream processes from printing to curing and packaging; reduces last-minute reprints and enables scalability. |

| Measuring success | Track setup time per job, daily throughput, material waste, color consistency, changeover frequency, and ROI to validate impact. |

| Practical guidance | Assess compatibility with current RIP/printers, define success metrics, start with a pilot, train users early, and plan for scale as volumes grow. |

Summary

DTF gangsheet builder is a transformative tool for apparel production, streamlining prepress layouts and boosting throughput. By automating layout tasks and ensuring optimal use of film, it reduces waste, shortens setup times, and improves color consistency across designs on a sheet. The case study demonstrates measurable gains after six months, including faster changeovers, higher throughput, and more predictable production. For teams aiming to stay competitive, adopting a DTF gangsheet builder aligns design, production, and finishing into an efficient, scalable system.