DTF Gangsheet Builder: Boosting Production Speed and Quality

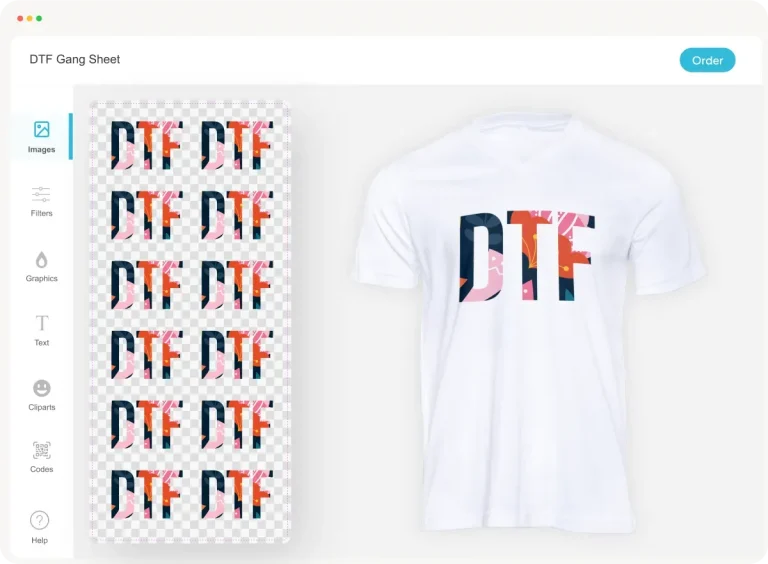

DTF gangsheet builder is revolutionizing how shops plan transfers, turning scattered artwork into a tightly packed, production-ready sheet. By automatically arranging multiple designs, it accelerates production speed and supports consistent results across runs. This tool integrates with DTF printing workflows to optimize the entire process, boosting efficiency, waste reduction in DTF, and overall production performance. With careful layout and bleed management, it improves gangsheet production while maintaining color accuracy across designs. If you aim to scale your apparel output, implementing this layout tool can cut setup time and drive cost-effective throughput.

A closely related concept is a sheet-level layout optimizer for transfer printing, sometimes called batch layout generation or transfer sheet automation. This reframing focuses on how many designs fit on a single sheet, how margins and bleeds are managed, and how the cut paths are planned to speed finishing. Viewed through the lens of workflow efficiency, these terms point to improvements in gangsheet production, production speed, and color management across batches. Using this perspective helps designers and operators align prepress practices with broader goals of DTF workflow optimization, waste reduction in DTF, and consistent results.

Maximizing Production Speed with DTF Gangsheet Layouts

A DTF gangsheet builder automatically arranges multiple designs on a single transfer sheet, dramatically increasing sheet density and reducing downtime between jobs. By optimizing layout geometry, margins, bleeds, and gutters, more designs fit onto each sheet without compromising print quality, which directly boosts production speed in DTF printing and enhances gangsheet production throughput.

The speed gains extend from prepress to final output. When integrated with RIP software and ICC profiles, the builder maintains color accuracy while streamlining file preparation, reducing prepress time and minimizing misfeeds. This level of production speed—accelerated by fewer setup changes and predictable cutting paths—embodies true DTF workflow optimization that helps a shop scale its output without sacrificing consistency.

Maximizing Production Speed with DTF Gangsheet Layouts (Continued)

As operators leverage standardized gangsheet templates and repeatable layouts, downstream finishing becomes more predictable. A well-constructed gangsheet not only prints more designs per sheet but also simplifies trimming and separation, cutting cycle times and enhancing overall throughput in the production line.

In practice, shops that adopt a DTF gangsheet builder often report meaningful increases in production speed, driven by higher sheet density and reduced rework. The result is a more efficient workflow from the initial design file through to the finished garment, illustrating how optimized gangsheet production can transform day-to-day operations.

Waste Reduction and Consistency Gains through DTF Workflow Optimization

Waste reduction in DTF emerges when layouts are optimized to minimize unused material, gaps, and misprints. A DTF gangsheet builder contributes to this by packing designs efficiently onto each sheet and by automating bleed management, which reduces scrap and wasted ink across the production cycle.

Standardized layouts, predictable trimming, and controlled color management all play a role in reducing waste. By aligning with a concise set of ICC profiles and a repeatable prepress workflow, shops achieve steadier output quality and lower material costs, underscoring how production efficiency and waste reduction in DTF go hand in hand.

Waste Reduction and Consistency Gains through DTF Workflow Optimization (Continued)

Implementing best practices—pilot programs, library templates, and automated preflight checks—helps quantify waste reductions and consistency improvements. Regular audits of finished products guide template refinements, ensuring that the gains from DTF workflow optimization are durable and scalable.

To maximize impact, teams should track KPIs such as material waste per batch, sheets printed per hour, and color stability across runs. A disciplined, data-driven approach to DTF workflow optimization ensures sustained improvements in waste reduction and overall print quality.

Frequently Asked Questions

How can a DTF gangsheet builder improve production speed and waste reduction in DTF printing and overall DTF workflow optimization?

A DTF gangsheet builder accelerates production and reduces waste by automating layout and optimizing sheet usage. Key benefits include:

– Higher sheet density: more designs per gangsheet, cutting the number of print runs and boosting production speed in DTF printing.

– Faster prepress: automated placement, consistent margins, and bleed management shorten setup time, enhancing DT F workflow optimization.

– Fewer misprints: precise alignment and automated bleed reduce scrap and reprints.

– Smoother downstream processing: standardized gangsheet layouts improve trimming accuracy and color management under RIP workflows.

– Waste reduction: optimized packing minimizes unused material, lowering material costs and waste in DTF production.

What best practices help maximize production speed and minimize waste when using a DTF gangsheet builder for gangsheet production?

To optimize production speed and waste reduction in DTF gangsheet production, follow these best practices:

– Standardize design sizes and align with RIP/printer capabilities to ensure layouts translate cleanly to the sheet.

– Create reusable layout templates and templates for common sheet sizes to speed up new jobs.

– Calibrate printers regularly and maintain consistent ICC profiles for stable colors across gang sheets.

– Run automated preflight checks for bleed, margins, and color accuracy before printing.

– Start with controlled pilots to quantify speed gains and waste reductions, then scale.

– Track KPIs (sheets per hour, waste per batch, setup time) to drive continuous improvement.

– Train operators and maintain a clean design library to support consistent gangsheet production.

| Aspect | Key Points |

|---|---|

| What is a DTF gangsheet builder? | A design-to-print efficiency tool that automates the placement of multiple artwork files on a single transfer sheet (gangsheet). It takes inputs like artwork files, color profiles, print margins, and sheet dimensions to generate an optimized layout that maximizes the number of designs per sheet while preserving print quality. |

| Core tasks |

|

| Benefits: Production speed |

|

| Waste reduction and efficiency gains |

|

| Integrating into workflow |

|

| Best practices for maximizing benefits |

|

| Real-world gains |

|

| Getting started |

|