DIY DTF Transfers: Create Stunning Designs at Home

DIY DTF transfers are revolutionizing the world of custom apparel printing, allowing enthusiasts to create stunning designs right from their own homes. This innovative method, known as Direct-to-Film (DTF) printing, enables seamless application of colorful images on various fabrics, making it a perfect choice for those eager to explore DIY custom designs. By utilizing DTF printing equipment, hobbyists and small business owners alike can produce vibrant, lasting prints without the need for professional assistance. Understanding how to use DTF transfers could transform your creative projects, whether you’re styling t-shirts, hats, or other personalized items. Embrace the trend of DIY DTF transfers and discover the potential of affordable, home-based customization for your wardrobe.

When it comes to crafting personalized garments, the realm of DIY Direct-to-Film (DTF) application stands out as a popular choice. Often referred to as DTF printing, this method involves the use of specialized transfer films to imprint unique designs onto various fabrics effortlessly. The versatility of this technique allows users to engage in custom apparel creation, perfect for both personal use and small entrepreneurial ventures. With the right tools and know-how, anyone can dive into the rewarding process of producing their own custom designs for clothing and accessories. Explore the exciting opportunities that DIY DTF printing offers and bring your imaginative ideas to life with ease.

The Process of DIY DTF Transfers Explained

Understanding the process of DIY Direct-to-Film (DTF) transfers is essential for anyone looking to delve into custom apparel design. The journey begins by creating or selecting a digital design that resonates with your style. This design is then printed onto a specialized transfer film using a DTF printer, which lays down vibrant ink in a way that ensures clarity and detail. After printing, an adhesive powder is applied to the wet ink, bonding perfectly during the heat transfer process. This multi-step procedure is what gives DTF its reputation for producing high-quality, durable designs that withstand the test of time.

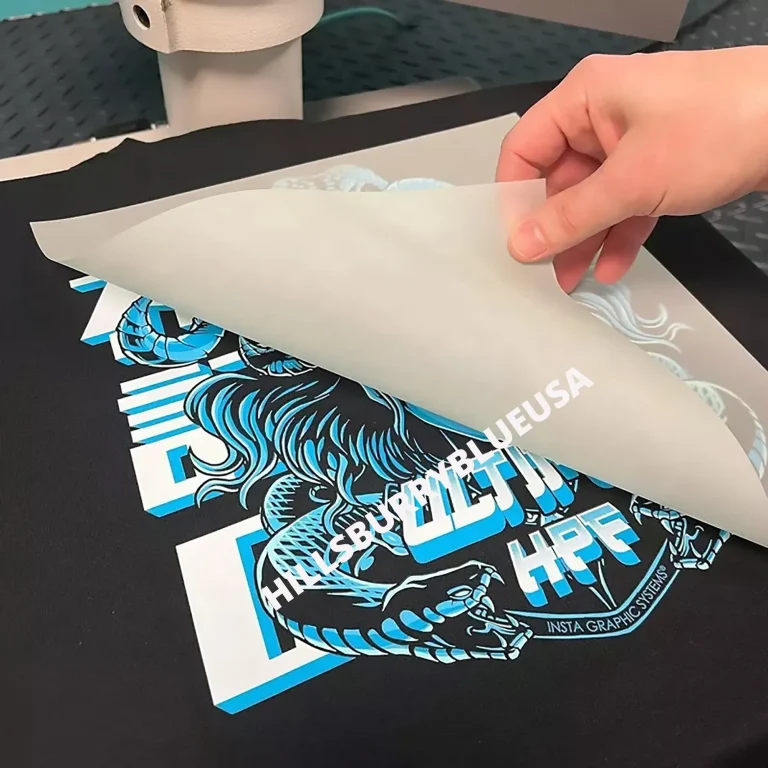

Once the adhesive powder is applied, the film is then placed onto the selected garment, ready to be heat-pressed. The heat press needs to be set to the correct temperature and pressure to activate the adhesive, allowing the design to bond firmly to the fabric. This is where the versatility of DTF transfers shines as they can be utilized across various fabric types—from cotton to polyester blends. It’s a straightforward process that provides endless opportunities for creative expression in custom apparel.

Key Equipment for Successful DTF Printing

To embark on your DIY DTF transfer journey, investing in the appropriate equipment is crucial. At the heart of your setup is the DTF printer, capable of printing images onto transfer film with precision. Popular options include brands like Epson, which are often recommended for their compatibility and quality at an affordable price point. In addition, the transfer film itself plays a vital role; it needs to be of high quality to endure the application process and deliver vibrant results.

Another essential component is the adhesive powder. This powder must be specifically designed for DTF transfers, offering optimum bonding capability once it undergoes the heat-pressing process. Additionally, a reliable heat press machine is indispensable. Look for a model with adjustable heat and pressure settings, as these adjustments can significantly impact the quality of your finished design. Lastly, graphic design software is essential for preparing your artwork to ensure it translates beautifully onto fabric.

Tips for Perfecting Your DTF Transfers

Achieving stunning results with DIY DTF transfers requires attention to detail and a willingness to learn. One of the first tips is to select the right fabric. Starting with 100% cotton or polyester is recommended, as these materials provide the best surface for adhesion. Pre-washing your fabrics to remove any chemicals is also beneficial, as it promotes a higher quality bond between the transfer and the material. Additionally, opting for the highest print quality settings on your DTF printer will ensure that the details in your designs are crisp and clear.

Another vital tip is to experiment with different designs and color palettes. DTF transfers thrive on vibrant, bold colors, and testing various designs on scrap fabric can help refine your techniques before you commit to your final products. Don’t hesitate to engage in community resources such as online forums or social media groups dedicated to DTF printing. These platforms can provide valuable insights, troubleshooting tips, and inspiration from other creators who share similar interests.

Exploring the Benefits of DTF Printing

The popularity of DIY DTF transfers can be attributed to their myriad benefits. One of the most significant advantages is color vibrancy. DTF printing technology enables the replication of complex designs with stunning color saturation, making it an excellent choice when producing custom graphics. Whether it’s simple logos or intricate art, the results are sure to impress, providing a professional finish that’s hard to achieve with other methods.

Moreover, the flexibility of DTF transfers allows creativity to flourish, as they can be applied to a wide range of fabrics, including cotton, polyester, and blends. This gives designers the freedom to conceptualize various garments, from T-shirts to bags. Another distinct advantage is cost-effectiveness. As mentioned, DIY DTF transfers can be created at a fraction of the cost of professional services, making it an ideal option for both hobbyists and aspiring small business owners.

Current Trends in DIY DTF Printing

As the world of custom apparel evolves, DIY DTF transfers are increasingly in vogue, especially within small business sectors and among creative enthusiasts. This surge is fueled by a growing consumer desire for unique, personalized clothing options. As more individuals become aware of and interested in creating custom products, the accessibility and affordability of DTF printing continue to support this trend, allowing for a more significant market presence.

Recent analytics reveal an increase in online searches related to DTF printing equipment and processes, indicating a burgeoning interest in learning how to make DIY DTF transfers. These trends suggest an ongoing shift towards customization in fashion, as potential entrepreneurs look for ways to leverage DTF technology to meet the growing consumer demand for tailored apparel, setting the stage for further innovations and developments in the industry.

Getting Started with DIY Custom Designs

Starting your journey with DIY custom designs using DTF transfers is an exciting prospect filled with creative possibilities. Initially, consider what type of apparel you wish to customize and design your graphics accordingly. You can use software like Adobe Illustrator to create high-quality visuals that resonate with your style. As you gather your equipment, remember that the DTF printer and the right types of transfer film will be key components to achieving seamless prints.

Once you have your designs prepared, make sure to familiarize yourself with both the process and the equipment. Set up your workspace in a way that facilitates an efficient workflow, enabling you to streamline the transition from printing to pressing. With practice and patience, anyone can master DTF printing, turning imaginative concepts into reality on garments that can be proudly worn or sold.

Frequently Asked Questions

What are DIY DTF transfers and how do they work?

DIY DTF transfers, or Direct-to-Film transfers, involve printing your custom designs onto a special film. After the design is printed, an adhesive powder is applied, followed by heat pressing onto fabric. This method is known for vibrant colors and excellent durability, making it perfect for custom apparel printing.

What equipment do I need for DIY DTF transfers?

For successful DIY DTF transfers, you’ll need a DTF printer like an Epson model, high-quality transfer film, adhesive powder, and a reliable heat press machine. Additionally, design software such as Adobe Illustrator can help you create stunning visuals for your DTF printing projects.

Can I use any kind of fabric for DIY DTF transfers?

Yes, DIY DTF transfers are versatile and can be applied to various materials, including 100% cotton, polyester, and blended fabrics. Choosing the right fabric is crucial for ensuring vibrant colors and durability in your final product.

How do I create custom designs for DTF printing?

Creating custom designs for DIY DTF transfers can be done using graphic design software. Programs like Adobe Illustrator or free alternatives such as GIMP allow you to design unique graphics. Ensure your designs are high-resolution for the best print quality.

What are some tips for using DTF transfers successfully?

To ensure successful DIY DTF transfers, start with pre-washed fabric, use high print quality settings on your printer, and always conduct test transfers on scrap fabric. Experiment with bold colors and intricate patterns to enhance your designs.

Where can I find resources and community support for DIY DTF transfers?

Many online communities, including social media groups and YouTube channels, provide valuable resources for DIY DTF transfers. You can find tutorials, troubleshooting tips, and connect with others who are exploring this exciting area of custom apparel printing.

| Key Point | Details |

|---|---|

| What Are DTF Transfers? | DTF transfers involve printing a design onto a specially coated film, applying adhesive powder, and heat-pressing it onto fabrics. |

| Advantages of DTF Transfers | 1. Vibrant Colors: High color saturation for complex designs. 2. Versatility: Works on cotton, polyester, and blends. 3. Cost Efficiency: Costs can be as low as $1-$2 per transfer. 4. Beginner-Friendly: Accessible to everyone, no expert skills needed. |

| Essential Equipment | 1. DTF Printer (e.g., Epson) 2. Transfer Film (high quality) 3. Adhesive Powder 4. Heat Press Machine (adjustable settings) 5. Design Software (Adobe Illustrator, GIMP) |

| Tips for Success | 1. Use suitable materials (cotton/polyester). 2. Ensure high print quality. 3. Experiment with designs. 4. Test transfers on scraps. 5. Join community resources for tips. |

| Market Trends | 1. Growth in customization demand for apparel. 2. Increased online searches for DTF equipment and techniques. |

Summary

DIY DTF transfers have revolutionized the way we create custom apparel, making it simpler and more accessible for everyone. By utilizing Direct-to-Film technology, you can create vibrant, durable designs that adhere beautifully to various fabrics. Whether you’re an individual looking to express your creativity or a budding entrepreneur aiming to enter the customization market, mastering DIY DTF transfers enables you to unleash your artistic potential. As interest in personalized clothing continues to rise, investing in this technique and its associated equipment offers not just a rewarding hobby, but also a viable business opportunity. Embrace the world of DIY DTF transfers today and bring your unique visions to life on fabric!