California DTF Trends: What’s New in Direct-to-Film Printing

California DTF Trends are reshaping the apparel printing scene, reflecting a dynamic mix of consumer demand, rapid technology shifts, and regional entrepreneurship. Direct-to-Film printing has moved from a niche technique to a mainstream option for small studios and established brands alike, and California—with its diverse markets, fashion-forward consumers, and a robust network of suppliers—has emerged as a bellwether for what’s next. If you’re a printer, brand owner, or designer, understanding these trends helps you anticipate changes in costs, workflows, and product capabilities, while also spotting opportunities to differentiate through quality, speed, and sustainability. This article outlines what’s new in DTF technology and how innovations are affecting producers in California, offering practical takeaways you can apply to your business or creative projects, from color management to on-demand production. As the market evolves, printers and brands can leverage DTF inks and substrates, evolving printing techniques, and sustainable sourcing to stay competitive.

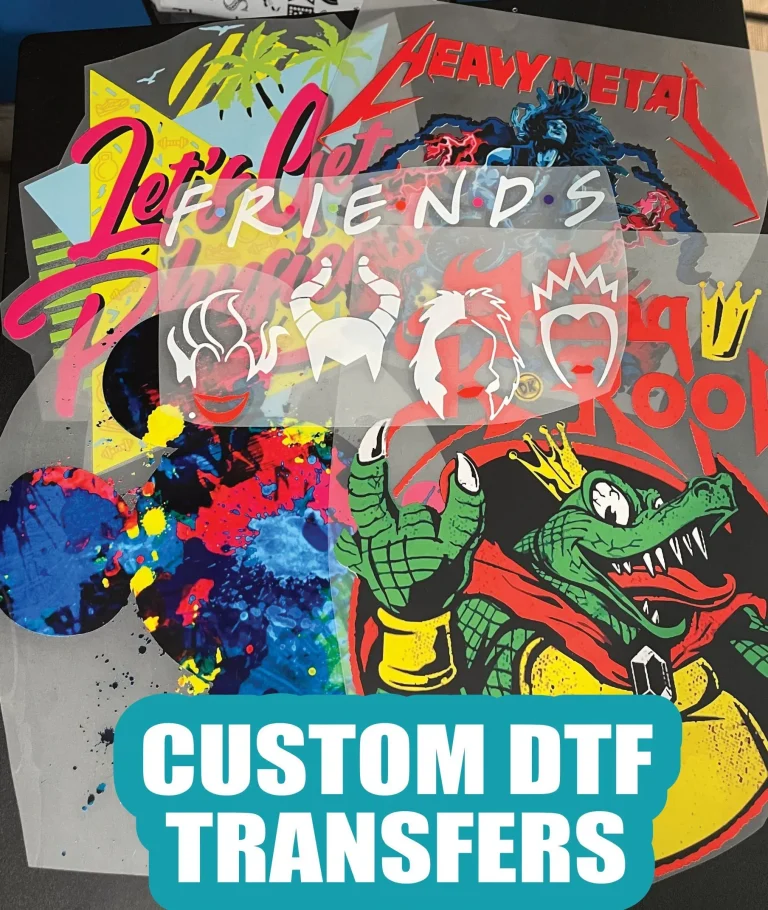

Beyond the headline terminology, the conversation shifts to film-transfer technology and its growing role in garment decoration, where heat activates transfer films to produce bold graphics. This approach, also known as film-to-fabric transfer or film-based digital transfer, relies on specialized inks and compatible substrates to deliver durable results on a wide range of fabrics. In California, startups and established print shops are testing optimized workflows, cost efficiencies, faster turnarounds, and sustainable material choices. Applying Latent Semantic Indexing principles, designers and printers connect related topics such as digital transfer, heat-press processes, substrate compatibility, and color-accuracy considerations to expand idea discovery. As the ecosystem evolves, staying abreast of ink chemistry, binding methods, and supplier networks will matter as much as refining the core transfer technique.

California DTF Trends: What’s Driving the Shift in 2025

California DTF Trends are reshaping the apparel printing landscape as consumer demand grows, technology accelerates, and regional entrepreneurship expands. Direct-to-Film printing has graduated from a niche technique to a mainstream option, with studios and brands alike leveraging its flexibility to offer short runs, quick turnarounds, and vibrant designs. In California, where fashion-forward audiences and a robust supplier network converge, these trends often set the pace for what’s next in digital textile production.

As printers, brand owners, and designers scan the market, understanding California DTF Trends helps forecast shifts in costs, workflows, and product capabilities. The evolving emphasis on quality, speed, and sustainability is driving changes in ink formulations, substrate choices, and finishing methods, all of which influence how Direct-to-Film printing tools are deployed across shops—from small studios to larger brands. This section examines the current state of DTF printing techniques and how regional dynamics shape outcomes.

Direct-to-Film Printing for Small Studios: Workflow Wins and Challenges

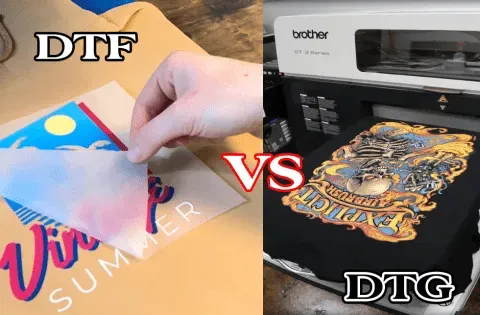

For small studios, Direct-to-Film printing offers a compelling combination of lower setup costs and scalable production. DTF printing techniques enable rapid prototyping, on-demand runs, and broader design experimentation without the need for large inventories. This flexibility is particularly valuable in California’s diverse markets, where niche designs and local collaborations can quickly become profitable offerings.

However, small teams must navigate challenges such as film and ink costs, color consistency, and the multiple steps involved in the workflow—from film preparation and printing to transfer and curing. Understanding how DTF inks and substrates perform across different fabrics helps studios minimize waste and optimize cure times, ensuring durable results that meet consumer expectations for color fidelity and wash durability.

DTF Printing Techniques: Innovations Shaping Color and Texture

DTF printing techniques continue to evolve, pushing color accuracy and texture to new levels. Innovations include improved white ink layering, sharper edge definition, and more reliable film-to-fabric adhesion across a wider range of fabrics. These advances enable designers to realize vibrant, photo-realistic imagery on garments while maintaining efficient production flows.

The ongoing development of Direct-to-Film printing technology also intersects with material science, as new DTF inks and substrates are engineered for better colorfastness, reduced bleeding, and faster cure cycles. As California studios experiment with nuanced textures and multi-color overlays, understanding these methodological shifts is essential for delivering premium results at speed.

DTF Inks and Substrates: Selecting Materials for Performance

Choosing the right DTF inks and substrates is central to achieving consistent color, durability, and cost efficiency. Ink chemistry determines color vibrancy, wash performance, and compatibility with different fabrics, while substrate quality influences film yield, transfer reliability, and texture feel on the final garment. Aligning these choices with production goals helps ensure repeatable results across orders.

Fabric compatibility, printability, and curing requirements are core considerations when selecting materials. Cotton and cotton blends, polyesters, and blends each respond differently to the same ink and substrate setup. By evaluating factors such as wash-fastness, gloss level, and hand feel, brands can optimize their DTF process for long-term customer satisfaction and reduced replacement costs.

DTF Trends in California: Market, Suppliers, and Retail Impact

DTF trends in California are heavily influenced by the state’s extensive supplier ecosystem—from film and ink manufacturers to heat-press equipment and automation providers. This interconnected network supports rapid experimentation and early adoption of the latest DTF printing techniques. Local education and hands-on demonstrations help studios and brands stay current with evolving best practices.

Retail dynamics in California—emphasizing fast fashion, customization, and sustainability—shape how DTF products are priced and represented. Brands may emphasize on-demand production, short lead times, and higher-quality finishes to differentiate in crowded markets. Understanding supplier lead times, material costs, and local talent pools helps businesses plan more reliable production calendars.

Sustainability and Speed: Winning DTF Strategies for California Brands

Sustainability is increasingly integrated into DTF workflows through responsible ink formulations, reduced waste, and efficient curing practices. By selecting eco-friendly DTF inks and substrates, brands can lower environmental impact while maintaining color fidelity and durability. The pursuit of sustainable options aligns with consumer expectations and regulatory considerations in California’s dynamic market.

Balancing speed with quality remains essential for California brands aiming to capitalize on rapid turnaround cycles. Streamlining the workflow—from print preparation to transfer and finishing—can reduce time-to-market without compromising the integrity of Direct-to-Film printing results. Emphasizing reliable DTF techniques, optimized curing, and materials that consistently perform across fabrics helps brands meet tight timelines while delivering premium products.

Frequently Asked Questions

What are California DTF Trends and why do they matter for printers and brands?

California DTF Trends describe how Direct-to-Film printing is reshaping the state’s apparel scene, driven by consumer demand, rapid tech shifts, and regional entrepreneurship. Direct-to-Film printing has moved from niche to mainstream in California, supported by a robust supplier network and diverse markets. Understanding these trends helps printers anticipate cost changes, adapt workflows, and differentiate through quality, speed, and sustainability.

How is Direct-to-Film printing evolving in California, and what does that mean for your shop?

In California, Direct-to-Film printing is now a mainstream option for both small studios and established brands. The trend brings new workflows, equipment needs, and faster turnarounds, with a strong California supply chain of inks, films, and substrates. For shops, this means watching costs, optimizing DTF workflows, and exploring opportunities to win with color quality and quick delivery.

What DTF printing techniques are seeing wider adoption in California today?

Common DTF printing techniques in California include layered color builds with white underbase, flexible curing for different fabrics, and considerations for hot-peel versus cold-peel finishes. Operators experiment with multi-pass and edge finishing to improve durability on cottons, blends, and performance fabrics. These techniques align with California DTF Trends toward premium feel, vibrant color, and reliable wash-fastness.

Which DTF inks and substrates work best for California apparel markets?

Choosing DTF inks and substrates in California depends on fabric type, desired vibrancy, and durability. Pigment-based DTF inks on polyester and cotton blends deliver bright colors with good wash fastness when paired with compatible substrates. Look for inks and films optimized for California wearability, low odor, and compatibility with your printer’s profile to balance color fidelity and cost.

What are the cost and workflow implications of California DTF Trends for small shops?

California DTF Trends influence costs through printer investment, film, ink consumption, and substrate pricing, as well as energy and maintenance. Workflow implications include faster setup, standardized color management, and tighter production scheduling to meet California deadlines. Planning for waste reduction and supplier lead times in California can improve margins.

How can brands in California leverage DTF trends to differentiate through quality, speed, and sustainability?

Brands can differentiate by selecting high-quality DTF inks and substrates, optimizing print and cure parameters, and investing in quality control. Partnering with local California suppliers reduces lead times and lowers transport emissions, supporting speed to market and sustainability goals. Emphasize durable finishes, certifications, and responsible waste practices to align with California consumer expectations.

| Key Point | Description | California DTF Trends Implications | Notes / Examples |

|---|---|---|---|

| DTF is moving from niche to mainstream | Direct-to-Film printing has shifted from a niche technique to a mainstream option for small studios and established brands. | Wider adoption in California studios; potential changes in pricing, supply chain demand, and service capabilities. | Reflects broader industry shift; opportunities for early adopters in CA. |

| California as a bellwether | California’s diverse markets, fashion-forward consumers, and strong supplier network position it as a leading indicator for trends. | What’s next for CA can signal nationwide trends in costs, workflows, and product capabilities. | Important for brand owners and printers targeting CA markets. |

| Stakeholders to watch | Printers, brand owners, and designers should monitor changes to anticipate costs, workflows, and capabilities. | In CA, changes in equipment, materials, and processing times may impact profitability and timelines. | Useful for planning investments and project scopes. |

| Differentiation through quality, speed, sustainability | Opportunities to differentiate by delivering high-quality prints, faster turnaround, and sustainable practices. | CA market expectations may reward sustainable sourcing and rapid delivery. | Focus areas for product development and supplier selection. |

| What’s new and practical takeaways | Article covers innovations in DTF printing, their impact on CA producers, and actionable tips for businesses. | Apply learnings to cost management, workflow optimization, and product capabilities in CA. | Useful for printers, brands, and designers in California. |

Summary

Conclusion will be provided after the table.