California DTF transfers: How to optimize for bright colors

California DTF transfers enable vibrant, durable prints across a wide range of fabrics by leveraging advanced color workflows and reliable film technology. To maximize results, prioritize DTF color management, calibrating monitors, proofs, and production outputs to maintain consistent brightness. A well-executed base layer on dark garments can dramatically improve perceived brightness and color fidelity. Choosing a high-quality transfer film and dense inks supports strong saturation, clean edges, and reduced color shift during transfers. By refining heat press techniques and testing on representative fabrics, you can achieve reliable, market-ready brightness.

From a terminology perspective, this topic can also be described as a direct-to-film process, a film-to-fabric transfer method, or a modern ink-on-film technology. These terms reflect a shared goal: consistent color fidelity, durable adhesion, and scalable production across apparel lines. For designers seeking bold outcomes, the approach can translate into bright color DTF prints when the workflow is right. When planning production, consider press parameters as part of a controlled, repeatable process—careful temperature, timing, and pressure drive consistency. By aligning terminology with measurable outcomes, this guide supports both creative exploration and practical, search-friendly content.

California DTF Transfers for Bright Color DTF Prints: Mastering the Basics

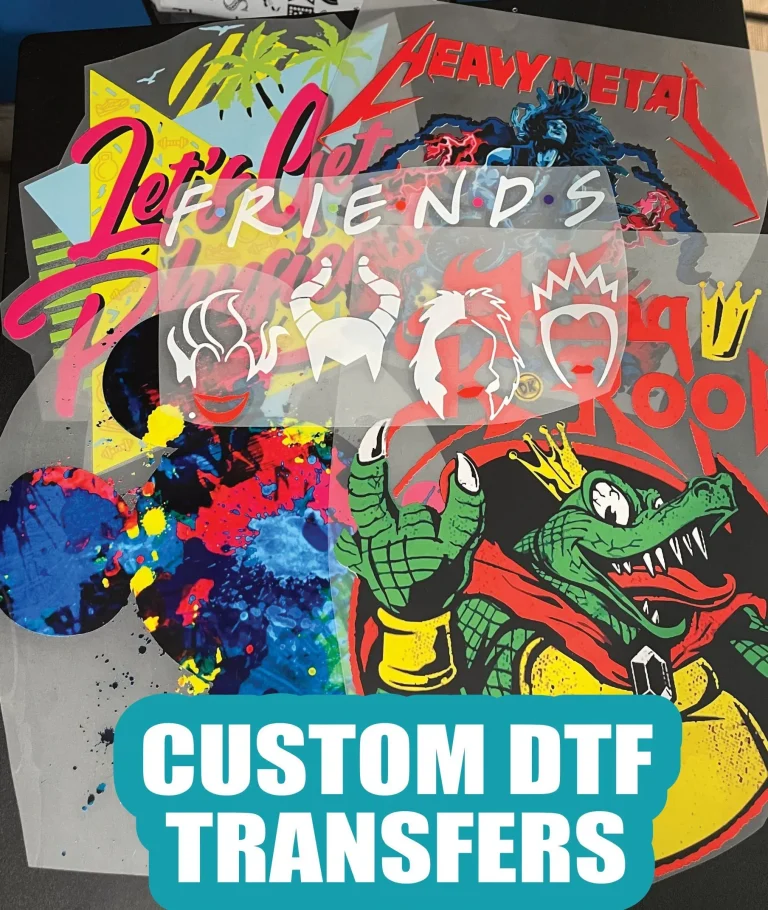

California DTF transfers have emerged as a reliable option for designers who chase vibrant, durable prints across a wide range of fabrics. When you aim for bright color DTF prints, these transfers offer strong color density, soft hand-feel, and good wash durability. Understanding the core of DTF transfers—from film to ink deposition—helps you set expectations for brightness and fidelity on different garment colors.

A foundational step is recognizing how California DTF transfers leverage a bright, opaque white underbase to maximize color punch, especially on dark fabrics. By prioritizing a robust white underbase for DTF, you create a clean canvas that preserves color intensity and reduces muddiness. With this baseline, you can better plan color layering and ensure consistent results across multiple productions.

DTF Color Management: Ensuring Vivid, Consistent Results

Effective DTF color management starts with calibrated workflows, including monitored proofs and accurate ICC profiles tailored to your printer and film. By aligning on-screen color with the final transfer, you minimize color drift and preserve the brightness of your designs across batches. This is essential when chasing the look of bright color prints on diverse fabrics.

In practice, implement proofing steps that compare small test prints to the actual garment color under consistent lighting. Document the exact color channel distribution for underbase and foregrounds, and adjust your workflow until you consistently reproduce the intended brightness. Strong DTF color management reduces surprises during production and helps you maintain vivid, reliable results.

Materials and White Underbase Strategies for Bold DTF Color

Choosing the right materials lays the groundwork for bold DTF color performance. Focus on transfer film quality that supports high color density and clean removal, paired with a white underbase solution that is compatible with your DTF inks. A reliable white underbase for DTF dramatically improves opacity on dark fabrics and enhances overall brightness.

Inks and printers play a pivotal role as well. Use inks formulated for DTF and maintain your printer with routine nozzle checks and head cleaning to prevent color loss or dulling. Pretreatment for cotton blends and darker fabrics can also stabilize color brightness, ensuring bright color DTF prints remain consistent across different substrate types.

Heat Press Settings and Process Flow for Bright DTF Transfers

Optimal heat press settings are essential for vibrant transfers. Focus on time, temperature, and pressure as a coordinated trio that drives color saturation and adhesion without causing ink bleed. For many DTF workflows, a typical starting window is around moderate to firm pressure with precise time and temperature control, then adjustments based on your specific film and ink used.

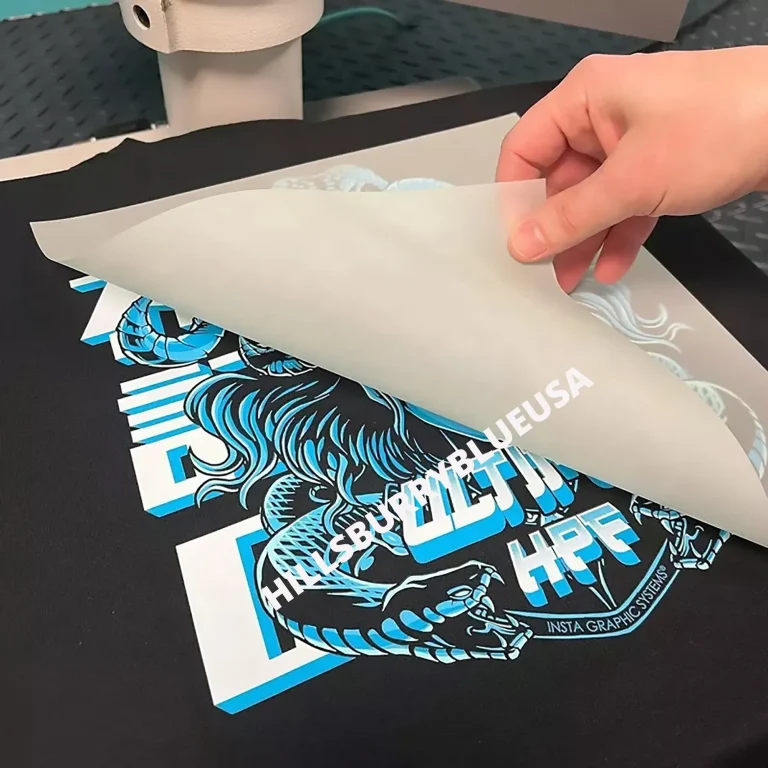

The press method and curing approach influence brightness longevity. Decide on a peel strategy (cold peel versus warm peel) based on your film’s recommendations and test results. Consistent post-press curing and controlled cooling help lock in color intensity, contributing to brighter, longer-lasting DTF transfers.

Print Workflow and Proofing for Bright Color DTF Transfers

A well-defined print workflow supports bright color DTF transfers from concept to final product. Start with color-rich artwork and plan white underbase areas that maximize brightness on dark garments. Convert to a suitable color space like sRGB and use proofing steps to simulate how the design will appear on fabric, aligning expectations with the actual transfer.

During print setup, ensure printer maintenance and nozzle health, and apply ICC profiles that reflect your printer, inks, and film. Run small test strips to verify color balance before committing to full runs, and document the exact settings for future batches. A disciplined workflow reduces color shifts and helps maintain bright color DTF prints across production lots.

Troubleshooting and Quality Assurance to Keep Colors Bright

Even with a solid workflow, issues can arise that dull brightness or affect color fidelity. Common symptoms include fading colors, halos, and inconsistent white underbase performance. Revisit color management, ink density, and heat exposure to identify where brightness is being compromised.

Implement structured quality assurance checks throughout a run, including batch-to-batch color comparisons and post-wash evaluations. Address white underbase issues by ensuring even deposition, and verify peel methods and post-press curing to prevent edge cracking or color bleeding. A proactive approach to troubleshooting helps sustain the bright, vivid look that California DTF transfers can deliver.

Frequently Asked Questions

What makes California DTF transfers effective for bright color DTF prints on dark fabrics?

California DTF transfers achieve bright color DTF prints by combining a strong white underbase for DTF with careful color management, high-quality transfer film and inks, and proper heat press settings. A calibrated workflow and test proofs help maintain vivid colors across batches.

What role does white underbase for DTF play in California DTF transfers for vibrant results?

The white underbase for DTF serves as the bright, opaque canvas that makes colors pop on dark garments. Ensure an even, well-deposited underbase using compatible inks and film, and verify curing and adhesion to prevent color dulling or muddiness.

What heat press settings are recommended for DTF transfers when using California DTF transfers (heat press for DTF)?

Recommended heat press settings typically include 160–180°C (320–356°F) for about 12–20 seconds with moderate to firm pressure (roughly 15 psi). Use a cold peel or warm peel per film guidance and pre-press the garment to remove moisture for consistent color transfer.

How does DTF color management impact color accuracy in California DTF transfers?

DTF color management involves calibrated monitors, ICC profiles, and proofing. Create or obtain profiles suited to your printer and film, proof on the garment color, and adjust color channels to preserve brightness and reproduce the intended vivid tones.

How do fabrics and substrates affect brightness when using California DTF transfers (DTF transfers) and what should you test?

Fabric choice greatly influences brightness. 100% cotton often yields the brightest results, while blends and polyester may require adjusted underbase and pressing parameters. Always test underbase density, color channels, and adhesion on each fabric type to maintain bright, consistent results.

What quality assurance steps help maintain long-term brightness in California DTF transfers (DTF color management) across production runs?

Implement a documented workflow with consistent ICC profiles, color checks at milestones, and wash/durability testing. Regularly verify color accuracy with small test runs, and keep notes on settings to prevent drift and preserve brightness over time.

| Aspect | Key Points |

|---|---|

| What are California DTF transfers? | DTF stands for direct-to-film: design printed on a thin film, then transferred with heat and pressure. Bright color reproduction; broad fabric compatibility (cotton, blends, polyester). White underbase is critical for brightness on dark garments; transfers rely on calibrated heat, film, and ink deposition. |

| Advantages for bright colors | Vivid color reproduction, durable, soft finishes; less cracking than some other methods. |

| Key factors that influence brightness | Color management, white underbase quality, film/ink quality, heat press settings, garment prep. |

| Materials to choose | Transfer film quality, white underbase materials, inks and printers, pretreatment and fabrics. |

| Color management steps | Calibrate workflow, use ICC profiles, implement proofing, optimize colors for bright results. |

| Step-by-step workflow (highlights) | Artwork prep with underbase planning; print setup with ICC/profile checks; dry/cure; transfer setup; heat press; post-press curing. |

| Practical tips | Robust white underbase; manage color density; even ink laydown; prevent misalignment; pre-test across fabrics. |

| Troubleshooting | Fading colors: check color management and underbase; bleeding/halos: verify peel and heat; underbase issues: ensure even deposition; edge cracking: adjust peel/cure; batch consistency: document settings. |

| Substrates & garment considerations | 100% cotton often yields brightest results; blends require pretreatment/testing; polyester challenges for underbase opacity; rib/textured fabrics may affect gloss; test swatches. |

| Quality assurance | Documentation of settings; consistency checks during runs; wash guidelines for end users; durability testing. |

| Why California DTF transfers stand out | Color management, strong white underbase, careful press settings; stable ink chemistry, advanced film technology, controlled workflow enable bright, vivid colors across fabrics. |

Summary

California DTF transfers deliver bright, durable colors by leveraging precise color management, robust white underbases, and carefully tuned heat-press parameters. This approach enables designs to maintain vibrancy across a broad range of fabrics, from 100% cotton to poly blends, with color accuracy that stays true from the first wear to the last wash. A well-documented workflow, pre-test strategy across garment types, and disciplined post-press curing are essential for reproducible results. By prioritizing underbase integrity, calibrated color profiles, and consistent press settings, brands can achieve eye-catching, long-lasting prints that celebrate California DTF transfers’ ability to keep colors bright and lively over time. Regular testing, batch documentation, and wash guidance for end users further support durable performance in real-world wear.