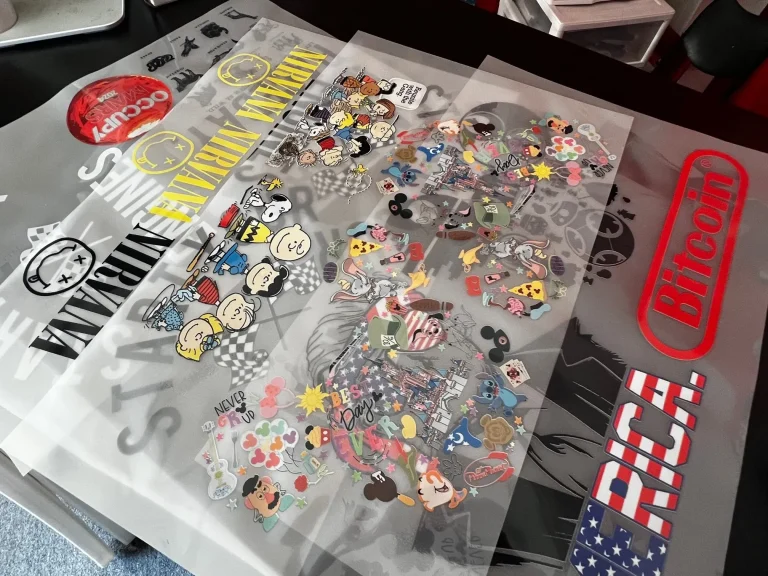

California DTF Printing: A Practical Direct-to-Film Guide

California DTF Printing has emerged as a practical gateway to Direct-to-Film technology for apparel decorators, small businesses, and in-house branding teams across the state. From Los Angeles studios to regional print shops, this approach blends bold color, durable transfers, and flexible workflows, aligning with Direct-to-Film technology principles and the growing demand for reliable DTF printing across diverse fabrics. The process covers steps from design and color management to printing onto DTF films, powder adhesion, curing, and a precise heat-press transfer that yields crisp details on a range of textiles. In California’s busy markets, shops prioritize scalable equipment, stable color management, and consistent quality checks to ensure DTF transfer quality and opacity on dark garments. This guide introduction primes readers to explore suppliers, workflows, and practical tips that help studios meet tight deadlines while expanding into on-demand, high-clarity transfers for local brands, teams, and events across California and beyond, for growth.

Direct-to-Film Technology: How DTF Printing Works

Direct-to-Film technology combines printed imagery on a PET film with a subsequent transfer to fabric. In DTF printing, a printer lays down CMYK inks and often a white underbase on the film, followed by adhesive powders and heat curing. This sequence creates a durable, vibrant result that preserves detail and opacity, especially on dark fabrics where opacity is critical.

In California markets, Direct-to-Film technology enables flexible runs, fast turnarounds, and a wide range of product types from team jerseys to fashion drops. By focusing on DTF films and reliable adhesive powders, studios can manage color consistency and transfer quality across multiple jobs, while maintaining a scalable workflow that supports short-notice orders and consistent DTF transfer quality across fabrics.

DTF Printing in California: Core Steps for a Consistent Workflow

Design and color planning set the stage for successful DTF printing. Start in your preferred software with proper color management, ensuring soft proofing matches what your DTF printers will produce on PET film. Use a layered approach: color-rich printable layer plus a white underbase for opacity when printing on dark fabrics, a common requirement in California apparel projects.

Printing on PET film is followed by powder adhesion and curing. The printers deposit CMYK inks (and white in a separate channel) onto the film, then adhesive powder is applied and cured before the transfer. The final heat press then transfers the design to fabric, with settings tuned to substrate and intended opacity to preserve DTF transfer quality.

Choosing the Right DTF Equipment for Reliable California Workflows

Selecting the right DTF equipment means pairing a capable DTF printer, compatible white ink, quality DTF films, and a reliable curing unit. Look for robust print heads, stable ink supply, and software that supports color profiles; ensure the white ink works well with your media to sustain opacity and color fidelity. DTF printers paired with appropriate DTF films produce consistent results across jobs and reduce the risk of banding.

Locating West Coast suppliers and planning for scale is essential in California. Start with a compact desktop DTF system for small runs, then upgrade to mid-volume printers and automation as demand grows. A predictable workflow—paired with standard operating procedures and QA checks—helps maintain DTF transfer quality and on-time delivery while you scale.

Color Management and Underbase Strategies for Dark Fabrics

Color management is the backbone of reliable DTF printing. Establish well-defined color profiles that translate screen designs onto the PET film with predictable results, then verify with printed samples. Regular printer calibration, ICC profiles, and controlled film tension guard against drift and help maintain consistent DTF printing output on a range of fabrics.

Opacity on dark fabrics hinges on a well-tuned white underbase. Test swatches on common colors (black, navy, heather) to determine white density and color balance. In California studios, this testing approach minimizes post-production surprises and contributes to smoother transfers and stable DTF transfer quality.

Common Issues and Troubleshooting in a Busy DTF Studio

Even with good planning, powder adhesion issues are a common stumbling block in DTF studio work. Uneven powder coverage, clumping, or improper curing can cause transfers to peel, crack, or misalign. Address these issues by using calibrated powder shakers, maintaining a controlled curing environment, and verifying film alignment before transfer.

Practical troubleshooting also includes pre-transfer test runs on similar fabrics, documenting settings, and adjusting curing times or temperatures for humidity and heater performance. These steps help protect DTF transfer quality and save time on larger runs by catching problems early.

Scaling from Desktop to Mid-Volume with California DTF Printing

Scaling from desktop to mid-volume in California DTF Printing requires a staged approach that preserves quality and profitability. Start with a solid desktop workflow that handles small runs efficiently, then add larger curing units, conveyors, or multi-head DTF printers as demand grows. Keeping a tight QA process ensures consistency across shifts and job types.

Crucially, maintain relationships with West Coast suppliers for films, powders, and inks, and document standard settings for each fabric. A repeatable workflow with clear color management, robust equipment, and ongoing testing positions California DTF Printing teams to deliver high DTF transfer quality at increasing volumes and tighter deadlines.

Frequently Asked Questions

What is California DTF Printing and how does Direct-to-Film technology work for apparel?

California DTF Printing uses Direct-to-Film technology to print designs on a PET film with CMYK inks (plus white), apply an adhesive powder, cure the film, and transfer the image to fabric with a heat press. This produces durable, vibrant transfers, especially on dark fabrics due to the white underbase, and supports on‑demand custom apparel in California studios.

What equipment does a California DTF Printing setup require, including DTF printers and DTF films?

A typical CA DTF Printing workflow needs a reliable DTF printer with white-ink capability, compatible DTF films, color and white inks, adhesive powder, a curing unit, and a heat press. Add color-management software and a standardized workflow to ensure consistent results across jobs.

How can California DTF Printing teams optimize color management to ensure consistent DTF transfer quality?

Start with a calibrated color profile and printer calibration tailored to your California media. Use layered designs, manage soft proofing, and maintain stable film feeding and curing to improve DTF transfer quality across runs.

What are common mistakes in CA DTF Printing and how can you troubleshoot transfer quality issues?

Common issues include uneven powder adhesion, over- or under-curing, and ink-banding. Troubleshoot by applying powder evenly, maintaining stable curing temperatures, aligning the film properly, and testing on representative fabrics to verify transfer quality.

How does DTF printing compare to DTG or screen printing in California DTF Printing workflows?

DTF printing excels for short-to-mid runs, high color density on a range of fabrics, and easy color management. DTG offers a softer hand on 100% cotton, while screen printing is cost-effective for large, identical runs. In California, DTF provides flexibility and faster turnarounds for varied client needs.

Where can California DTF Printing shops source DTF films and supplies?

Look to West Coast distributors and California suppliers for DTF films, powders, inks, and related consumables. Building relationships with local vendors helps secure reliable delivery, compatible components, and quick turnarounds for California DTF printers.

| Section | Key Points |

|---|---|

| What is Direct-to-Film (DTF) Technology? | – Transfers ink from CMYK (plus white) onto a PET film, then uses a heated transfer to fabric. – A powdered adhesive is applied and cured before transfer. – Results in durable, vibrant images with good opacity on dark fabrics. – Provides a flexible alternative to traditional screen printing and DTG, especially in California markets. |

| Why California Shops Are Turning to DTF Printing | – Enables short runs, quick turnarounds, and diverse product types. – Supports on-demand printing for fashion capsules, event merch, and campus programs. – Improves prepress speed and color management. – West Coast distributors make films and powders readily available for reliable workflows. |

| How DTF Printing Works: A Step-by-Step Overview | – Design and color management: prepare for opacity on dark fabrics; use layered design with white underbase when needed. – Print onto PET film: CMYK and white inks; ensure stable ink flow and alignment. – Apply adhesive powder: evenly coat wet ink and cure. – Cure the film: stabilize ink/powder and prevent smudging. – Transfer to fabric: set appropriate temperature, time, and pressure; white underbase for dark fabrics. – Post-transfer care: cool and set; perform wash tests and document settings. |

| DTF Equipment and Materials: Building a Reliable California Workflow | – Core components: DTF printer, PET film, white and color inks, adhesive powder, curing unit, heat press. – Focus areas: print head reliability, white underbase quality, film/powder consistency, and robust curing/press equipment. – Workflow scale: start desktop, grow to larger automated systems while maintaining standardized settings and QA. |

| Quality and Color Management in DTF Printing | – Establish defined color profiles and regular printer calibration. – Use ICC profiles and consistent film feed tension to maintain color fidelity. – Color management is crucial for California’s diverse client base and variable fabrics. |

| White Underbase and Opacity on Dark Fabrics | – White ink underbase improves opacity on dark garments. – Calibrate density to avoid cracking or stiffness; test swatches across common fabrics (black, navy, heathers). – Plan white density and color balance for each material, especially for teams and clubs that use dark apparel. |

| Powder Adhesive and Transfer Quality: Troubleshooting Tips | – Ensure even powder coverage with a calibrated shaker. – Maintain a stable curing environment to prevent clumping or migration. – Test transfers on similar fabrics before large runs and document results. |

| DTF vs Other Transfer Methods: Pros, Cons, and Fit | – DTF excels for short-to-mid runs with vibrant color and versatility across fabrics. – Not always the most cost-effective for very large runs on identical designs. – DTG may suit soft-hand on 100% cotton; screen printing can win on large volumes. – California studios should evaluate client needs, volume, and fabric types to choose the best method. |

| Practical Tips for a Successful DTF Studio in California | – Start with proper design prep and color management; test on target fabrics. – Build a reliable West Coast supplier network for films, powders, and inks. – Develop a repeatable workflow and document all settings for each fabric. – Test on common fabrics (cotton, poly-cotton, polyester) and implement QA checks. – Ensure ventilation, safety, and compliance with powders and solvents. |

| Scaling from Small Runs to Mid-Volume Production in California | – Use a staged approach: desktop systems first, then add automated capacity. – Maintain consistent processes, color management, and QA as you scale. – Leverage multi-head printers, larger curing units, and conveyors to increase throughput while preserving quality. – Plan for local demand from brands, schools, and events. |

Summary

Table explains the key points of the base content in English, summarizing Direct-to-Film (DTF) technology, California-focused workflows, equipment, color management, troubleshooting, comparisons with other transfer methods, practical studio tips, and scaling considerations for California DTF Printing.