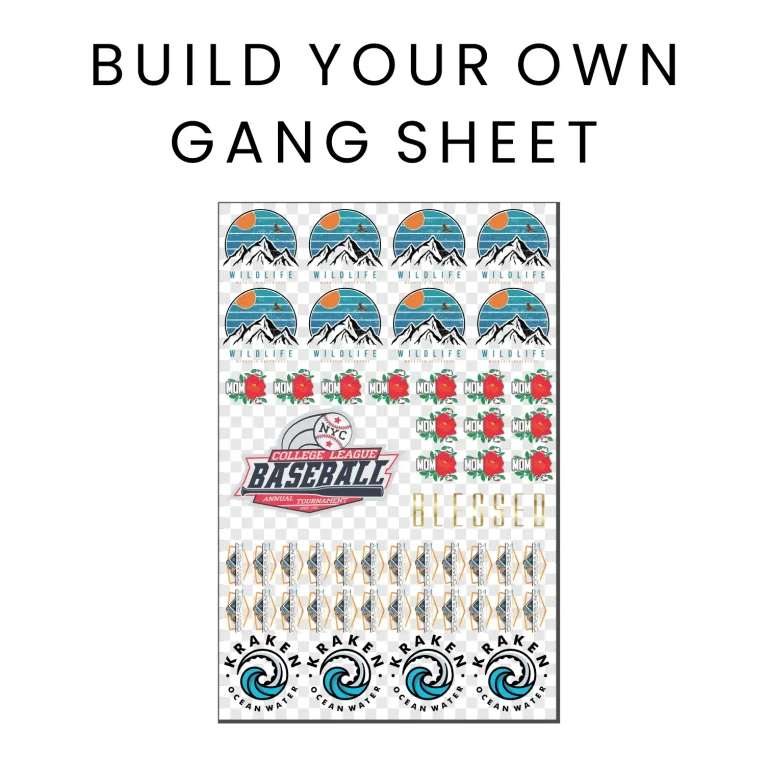

DTF gangsheet builder: Practical tips to boost throughput

DTF gangsheet builder is changing how shops approach on-demand apparel printing, making it easier to consolidate multiple designs onto a single sheet. By organizing artwork into optimal gangsheet layouts, you can maximize heat transfer efficiency and drive improved DTF printing throughput. This tool reduces setup time, minimizes waste, and supports practical DTF production tips for everyday operations. A well-designed workflow optimization plan is built around templates, color management, and predictable sheet usage. For shops aiming at high-volume DTF production, mastering a gangsheet builder is a scalable way to stay competitive.

In other words, think of it as a sheet-assembly engine that maps several graphics to one print panel, cutting waste and speeding up the run. Alternative terms like multi-design packing, batch layout planning, or print sheet choreography describe the same idea of pairing artwork for efficient trimming and transfer. From a process perspective, this concept supports route optimization, prepress automation, and reliable throughput across orders. Using a template-driven approach helps keep garment-specific print areas and margins consistent, laying the foundation for scalable production. When layout efficiency meets strict color management and hardware constraints, you achieve a resilient workflow that handles growth without quality loss.

Maximizing DTF Printing Throughput with a DTF Gangsheet Builder

Using a DTF gangsheet builder helps plan and place multiple designs on a single print sheet, dramatically increasing DTF printing throughput by maximizing sheet usage and reducing media changes. This approach minimizes downtime between jobs and enables you to print more units per pass, which is essential in high-volume DTF production.

Key to effectiveness are gangsheet layouts that respect printer constraints such as nozzle gaps, bleed, margins, and heat transfer zones. By locking templates, adopting intelligent auto-layout, and applying consistent color management, you can cut reprints and maintain steady throughput. These practices serve as core DTF production tips that support workflow optimization and predictable lead times.

Effective Gangsheet Layouts and Workflow Optimization for High-Volume DTF Production

Designing efficient gangsheet layouts means packing as many designs as possible without crowding, while accounting for trimming, heat transfer areas, and color management. In high-volume DTF production, well-planned gangsheet layouts reduce setup time, minimize waste, and improve queue management, enabling smoother production runs.

To maximize throughput, embrace DTF production tips like preflight checks, template libraries, and smart queue sequencing. Workflow optimization comes from planning entire runs, matching print areas, and standardizing color profiles across jobs. These practices help maintain color accuracy and reduce reprints, boosting DTF printing throughput across shifts.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it improve DTF printing throughput through smarter gangsheet layouts?

A DTF gangsheet builder is a tool (in RIP software or as a standalone app) that plans, arranges, and optimizes multiple designs on a single print sheet. By intelligently positioning designs, accounting for margins, bleed, and printer constraints, it maximizes sheet usage, reduces media changes, and lowers downtime, which boosts DTF printing throughput. Advanced builders support templates, automatic reflow for different sizes, bleed handling, and color-managed presets, all of which contribute to workflow optimization for high-volume DTF production.

What practical tips using a DTF gangsheet builder can help maximize throughput in high-volume DTF production?

Plan the day’s gangsheet run to minimize interruptions. Optimize gangsheet layouts for trimming and heat transfer by leaving safe margins and avoiding edge crowding. Use consistent design dimensions and templates across jobs to improve packing efficiency. Run preflight checks before printing to catch bleed, color, or placement issues early. Manage the print queue and job sequencing to minimize setup changes. Leverage automation for automatic reflow or space reallocation when designs are edited to save time and sustain high-volume DTF production.

| Key Point | Description | Notes / Relevance |

|---|---|---|

| What is a DTF gangsheet builder | A tool to plan, layout, and optimize multiple designs on one printing sheet, increasing sheet usage and throughput while reducing media changes. | Core concept |

| Throughput importance | Throughput affects lead times, margins, and consistency; higher throughput shortens lead times and reduces waste while enabling standardized color profiles. | Operational impact |

| Core concept: layout optimization | Goal is to fit as many designs as possible on a sheet without crowding, respecting nozzle gaps, ink distribution, and transfer areas. | Optimization balance |

| Getting started: sheet size and printer constraints | Define sheet size (A4/Letter or larger), margins, bleed, and printer limits; set defaults in the builder. | Initial setup |

| Template library | Create templates for common garment types and print areas to speed layouts and ensure consistency. | Standardization |

| Auto-layout and color management | Use auto-layout to place designs efficiently and apply color-managed presets and ICC profiles across the sheet. | Automation and color |

| Practical throughput tips | Plan the entire gangsheet run, optimize spacing for trimming, standardize dimensions, preflight, manage queue, use templates, and consider automation. | Actionable tips |

| Pitfalls to avoid | Overcrowding, inconsistent margins, poor file prep, underutilized templates, and misaligned post-processing increase waste and delays. | Quality risk |

| Quality and long-term efficiency | A well-structured gangsheet workflow delivers consistent quality at scale with predictable throughput and happier customers. | Outcome |

Summary

DTF gangsheet builder is a powerful ally for anyone looking to boost throughput and optimize DTF printing workflows. By planning layouts that maximize sheet usage, employing templates, and enforcing color management from the start, you can shorten lead times and reduce waste. A disciplined approach—define sheet sizes, use templates, leverage auto-layout, and conduct preflight checks—helps standardize processes across jobs and ensures reliable throughput at scale. In the long run, adopting a DTF gangsheet builder yields higher margins, scalable production, and the ability to meet growing demand with consistent quality.