DTF Gangsheet Builder: Case Study on 40% Production Boost

DTF Gangsheet Builder is redefining how shops scale production without sacrificing print quality, turning complex layouts into a repeatable, high-throughput process that drives consistency from first design to final print, and it does so with an intuitive interface that speeds onboarding and reduces errors. By streamlining how designs are packed on gang sheets, leveraging intelligent layout heuristics, and linking prepress with the printer queue, teams can achieve meaningful gains in DTF production efficiency across multiple jobs and substrates, while preserving color integrity and print fidelity. Automated layout, smart rotation, and robust bleed management cut setup times, reduce misplacement, and minimize material waste, delivering a clear win for DTF automation and enabling operators to focus more on creative decisions. Shops can expect faster turnarounds, improved color consistency, and smoother transitions between jobs—hallmarks of a more reliable and scalable printing workflow, with fewer bottlenecks and better predictability across shifts. The case study framing the technology, DTF case study, illustrates tangible gains, including a notable uptick in throughput and more reliable color matching across diverse runs, providing a practical reference for teams evaluating gangsheet-based solutions.

Seen from a broader perspective, a multi-design packing tool reshapes how artwork is arranged on printed sheets, aligning layouts with substrate realities and color management rules. This alternative framing highlights concepts such as layout optimization, prepress automation, and batch printing efficiency that underlie the same productivity gains described in the case study. By focusing on automated placement, bleed control, and queue integration, teams can shorten approvals, reduce manual handling, and improve overall throughput. By leaning into automation, standardized proofs, and template-based approaches, shops increase predictability and reduce rework across multiple orders. In short, these latent semantic indexing-inspired terms mirror the core advantages of gangsheet-driven processes, helping printers think in terms of efficiency, reliability, and quality across every job.

DTF Gangsheet Builder: Maximizing Throughput, Quality, and Alignment in DTF Printing

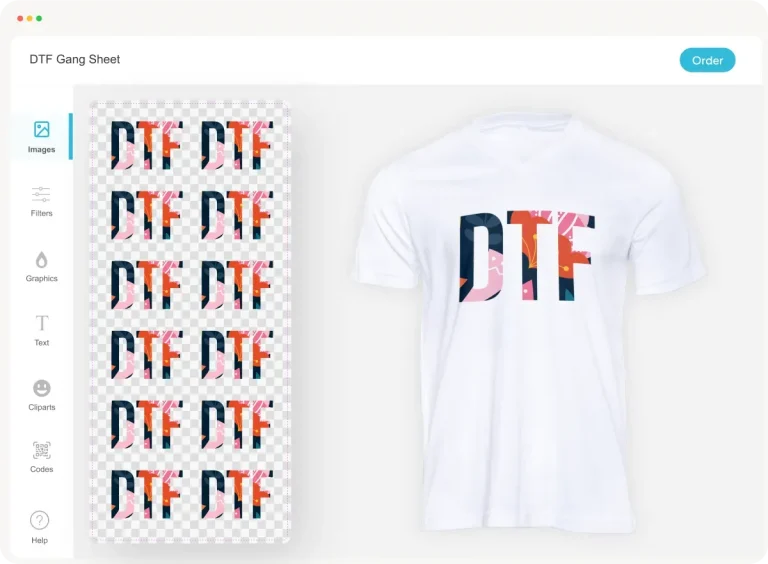

DTF Gangsheet Builder is a purpose-built tool that automatically arranges multiple designs on a single gang sheet, maximizing sheet usage and reducing waste. By applying layout optimization and intelligent packing, this feature accelerates the prepress phase and directly boosts DTF production efficiency, while delivering cleaner gangsheet printing results.

Because the builder integrates with your RIP and color management workflow, it minimizes mismatches, misalignment, and color bleed. Operators gain repeatable, high-throughput layouts, faster proofs, and more predictable changeovers, all of which contribute to a smoother printing workflow optimization.

As highlighted in the DTF case study, reorganizing layouts and automating prepress steps drove a 40% increase in production, proving the value of gangsheet-based automation for everyday shops. The lesson is that combining automated layout with standardized templates and staff training yields durable gains across throughput, waste reduction, and color consistency.

DTF Automation and Printing Workflow Optimization: From Layout to Output

DTF Automation transforms the prepress and print preparation steps by taking over layout, margins, bleeds, and orientation decisions from operators. This reduces human error, shortens setup times, and creates a repeatable gangsheet printing process that scales with demand. The automation layer works in concert with the RIP and printer profile to preserve color accuracy and consistency across jobs.

Across the full production workflow, automation delivers end-to-end improvements in printing workflow optimization. From file preparation to final output, the built-in checks and previews help verify layouts, margins, and color targets before a single impression is made, delivering faster proofs, fewer reprints, and steadier performance.

Real-world results mirror the case study: increased throughput, lower waste, and shorter changeover times. By documenting baseline metrics and tracking KPIs such as sheet utilization, color stability, and lead times, shops can quantify DTF case study-inspired gains and justify continued investment in automation.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it improve DTF production efficiency in gangsheet printing?

A DTF Gangsheet Builder is a tool—usually a software feature or a plug‑in within your RIP—that automatically arranges multiple designs onto a single gangsheet. It optimizes layout, supports rotation and mirroring, manages bleed and margins, and aligns with your printer’s color management workflow. This automation reduces manual layout work and handoffs, delivering a repeatable, high‑throughput process. For DTF production efficiency, gangsheet printing, and overall printing workflow optimization, it can boost throughput and reduce setup time, as demonstrated by case studies showing significant gains.

What lessons does the DTF case study offer about automation and gangsheet printing for faster, more reliable production?

From the DTF case study, automation via a gangsheet builder that integrates with the RIP and printer queue can substantially improve printing workflow optimization and DTF automation. The case study reports about a 40% increase in production, shorter changeover times, better material yield, and more consistent color. Best practices include defining standard templates, training staff to interpret previews and color targets, running pilots, and tracking metrics to sustain DTF production efficiency over time. These lessons show that gangsheet printing with automation reduces bottlenecks and elevates throughput.

| Topic | |

|---|---|

| What is a DTF Gangsheet Builder? |

|

| Baseline challenges before the case study |

|

| What changed in the case study |

|

| The impact on production and downstream metrics |

|

| Why this works: the science of packing and automation |

|

| Best practices for implementing a DTF gangsheet builder |

|

| Common challenges and how to address them |

|

| The broader implications for the industry |

|