DTF transfers: Creative ideas from design to dress

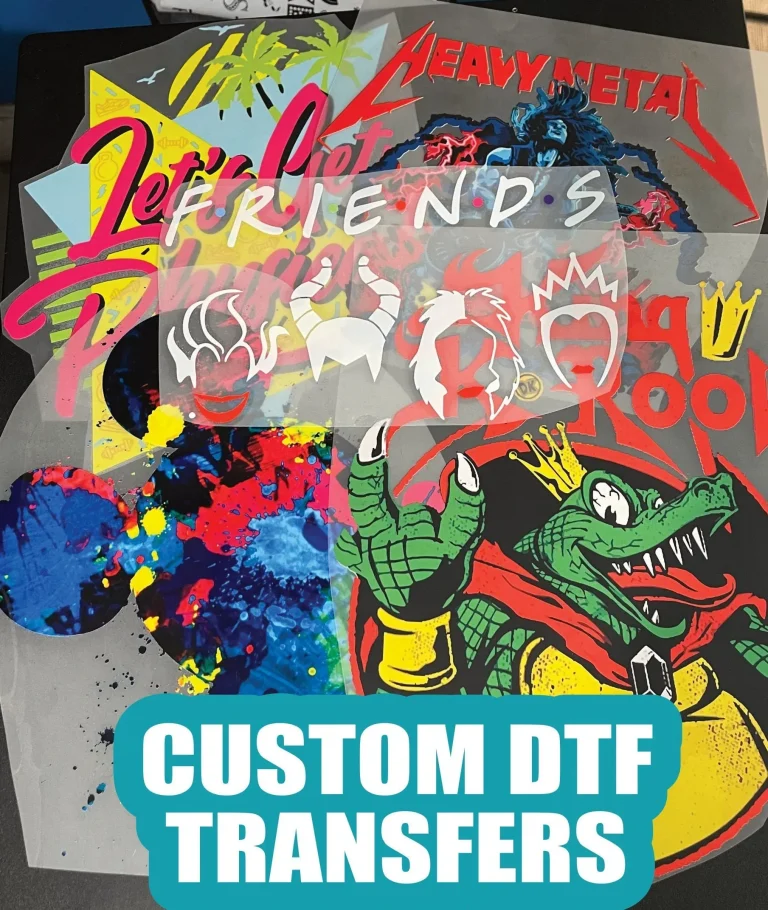

DTF transfers open a world where digital artwork becomes wearable, offering vibrant color, crisp detail, and durable results. From t-shirts to hoodies, designers leverage DTF transfer designs to translate complex images into fabric-friendly prints. As a form of heat transfer printing and DTF printing on fabrics, this method supports a broad range of fabrics and finishes while keeping production flexible for small runs. With careful design and color management, a creative t-shirt design with DTF can capture gradients and sharp edges that stand up to washing. Whether you’re a maker, boutique, or small brand, DTF transfers for apparel offer a scalable path from concept to wearable art.

Beyond the name, this approach is a direct-to-film (DTF) process that converts digital art into a removable, heat-activated graphic on textiles. Working with a transfer film and bonding powder, creators can achieve vivid imagery and fine gradients on a wide range of fabrics. LSI-friendly terms such as garment graphics, textile transfers, and print-on-fabric designs help describe the technique to both readers and search engines. By framing the concept as a flexible fabric decoration method, designers can explore small-batch apparel, accessories, and home textiles with consistent results.

DTF transfers for apparel: From concept to wardrobe

DTF transfers empower designers to transform digital art into wearable statements. The process preserves vibrant color, fine detail, and a soft hand feel that rivals traditional screen printing, making it ideal for bold graphics, gradients, and photographic imagery. Framed by DTF transfer designs, this method sits within the broader realm of heat transfer printing, offering a flexible path from concept to dress across a wide range of fabrics. Whether you’re printing on cotton, blends, or synthetics, DTF transfers enable apparel that looks as good after washing as it did on day one.

To move from design to dress efficiently, start with high-resolution artwork and a clear concept that suits your garment type. Prepare color separations if your workflow requires them, test swatches on target fabrics, and refine your parameters before full runs. The finishing steps—bonding, curing, and precise heat and pressure—are crucial for durability, and a thoughtful approach to DTF printing on fabrics helps you minimize waste and ensure consistent results.

Creative strategies with DTF transfer designs to elevate garments

Creative t-shirt design with DTF showcases how typography, gradients, and photographic motifs translate into wearable art. DTF transfer designs let you push color depth and detail across tees, hoodies, and even sleeves, while maintaining legibility and impact on various colors. This approach also opens doors to dynamic patterns and seamless repeats that can elevate collections through DTF transfers for apparel.

Beyond standalone prints, pair DTF transfers with embroidery, screen printing, or appliqué to add texture and storytelling. Invest in color management and test on multiple fabrics to preserve fidelity. By embracing multi-technique layouts and on-demand production using DTF transfer designs, designers can release limited drops and seasonal lines that stay fresh without sacrificing quality or workflow efficiency.

Frequently Asked Questions

Why are DTF transfers for apparel a versatile option for heat transfer printing across various fabrics?

DTF transfers for apparel offer vibrant color, fine detail, and broad fabric compatibility, making them a flexible alternative to traditional heat transfer printing. They support complex artwork, including photo-realistic images, and are economical for small runs. The standard workflow includes designing at high resolution (300 dpi or higher), printing onto the transfer film, applying bonding powder, curing, and transferring with heat and pressure. For best results, test on target fabrics, ensure precise alignment, and follow the manufacturer’s heat, time, and pressure guidelines to maximize durability on cotton, blends, and synthetics. Referencing DTF transfer designs in your artwork helps preserve color fidelity and readability.

How can I create a creative t-shirt design with DTF and ensure durable, color-accurate results when printing on fabrics?

Start with a high-quality, creative t-shirt design with DTF that translates well across colors and fabric types. Prepare artwork at 300 dpi or higher, separate colors if required, and choose DTF printing on fabrics suitable for the design. Print on the DTF film, apply bonding powder, cure, and transfer with a heat press using the manufacturer’s guidelines. Test on a sample fabric first to refine color, alignment, and texture, then provide care instructions to maximize longevity and washability.

| Aspect | Key Points |

|---|---|

| What are DTF transfers | A modern method to apply digital prints onto fabric using a transfer film, bonding powder, curing, and heat/pressure; offers color fidelity, durability, and broad fabric compatibility. |

| How it works (step-by-step) | Concept & design; Artwork prep (300 dpi+); Printing and bonding; Transfer application; Finishing & care. |

| Creative ideas | Typography on tees; Photo-realistic prints; Pattern repeats on sleeves or panels; Accent logos; Mix with embroidery or screen prints. |

| Materials & setup | DTF printer/film; Bonding powder; Curing equipment; Heat press; Garments/fabrics; Design software; Testing protocol. |

| Best practices for applying | Test prints; Align precisely; Follow manufacturer temp/time; Ensure even pressure; Post-press care. |

| Troubleshooting | Cracking/peeling edges; Fading; Smearing; White halo. |

| Care & longevity | Wash cold/warm; avoid harsh detergents; turn inside out; air dry when possible. |

| Advantages for apparel | Vibrant color, fine detail, works on many fabrics; cost-effective for short runs; good for photos/gradients. |

| Sustainability & efficiency | Less waste for small batches; flexible design testing; ongoing film/ink improvements. |

Summary

DTF transfers unlock wearable art by turning digital designs into durable, vibrant prints on fabrics. DTF transfer designs offer rich color fidelity and intricate detail across a wide range of fabrics, making them ideal for apparel. From concept and artwork prep to printing, bonding, and heat-press application, the DTF process supports experimentation and flexible production for small runs. Proper color management and care instructions help extend longevity, while DTF transfers for apparel empower designers to create creative t-shirt designs with DTF and expand into diverse product lines. With sustainability and efficiency advantages for small-batch production, DTF printing on fabrics opens a world of possibilities for designers and crafters alike.