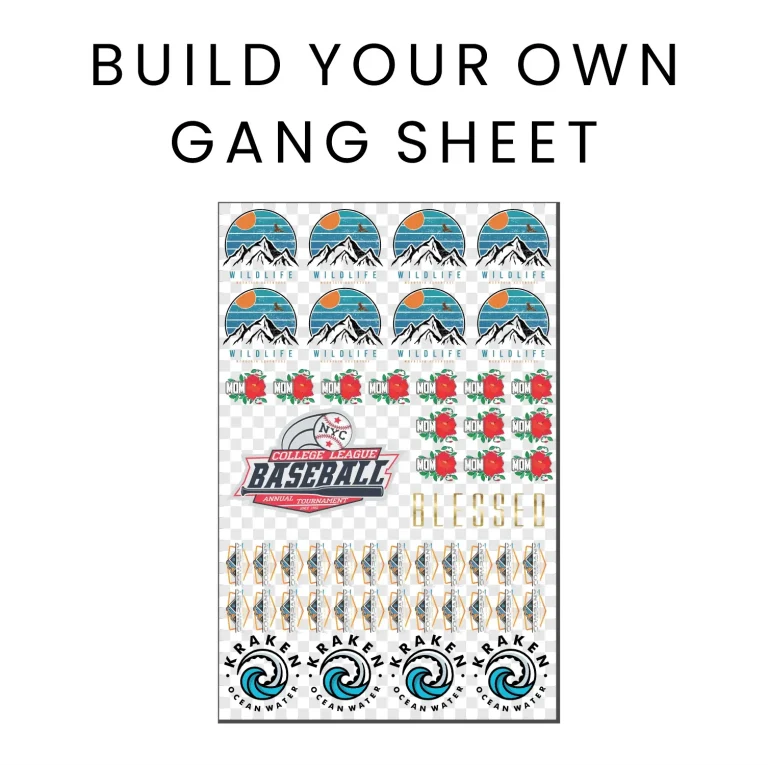

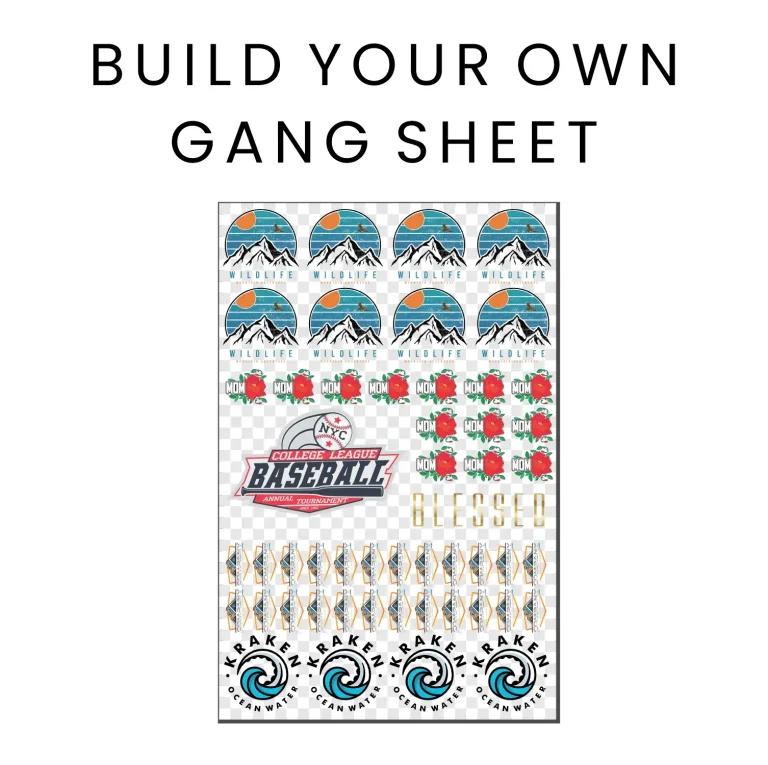

DTF gangsheet builder: 60% faster setup time Case study

DTF gangsheet builder transforms how shops plan and execute multi design sheets, delivering faster setup and more reliable cuts. By automating layout, color management, and cut line generation, it minimizes manual handling and accelerates the prepress phase, showcasing DTF automation benefits. With centralized templates for common garments and sizes, it supports DTF gangsheet setup, ensuring repeatable results across orders. Smart packing and intelligent spacing improve gangsheet cutting precision, reducing waste and misalignment at production. All told, this solution boosts DTF production efficiency and reinforces the DTF printing workflow for faster, more consistent output.

In other terms, a sheet oriented automation system for direct to film production serves as the backbone of the prepress and manufacturing workflow. It emphasizes layout optimization, color accuracy, and precise cut-path planning, using synonyms that align with broader print operations. By leveraging configurable templates and automated rules, studios move from manual juggling to repeatable, scalable runs. This latent semantic indexing oriented approach links production throughput, material utilization, and quality control, creating a more predictable output. Ultimately, embracing such a workflow yields faster ramp ups, steadier quality, and stronger efficiency across the DTF process.

DTF gangsheet builder: Accelerating setup and refining the DTF printing workflow

The DTF gangsheet builder unifies the core steps of DTF gangsheet setup, automated layout, color management, and cut-line generation into a single, template-driven workflow that dramatically reduces prepress effort and accelerates the DTF printing workflow.

By centralizing design templates and automating layout, color separations, and cut paths, the system improves gangsheet cutting precision and delivers measurable gains in DTF production efficiency, enabling faster turnarounds without sacrificing quality.

This approach also minimizes manual juggling of assets, standardizes prepress checks, and provides repeatable results across similar jobs, which strengthens throughput and sets a scalable foundation for growth.

DTF automation and precision: boosting production efficiency through precise gangsheet cutting

DTF automation in the gangsheet workflow coordinates artwork intake, template-driven layouts, and color separations with the printer and cutter hardware. This alignment tightens the DTF printing workflow from design to finish and enhances gangsheet cutting precision through exact cut-path generation and alignment marks.

With automated checks and standardized templates, production efficiency rises as changeovers are faster, miscuts drop, and material waste declines. The result is higher capacity, more consistent color reproduction, and a smoother path from prepress to production.

To maximize benefits, teams should invest in robust templates for top products, implement clear asset naming, calibrate hardware alignment, and monitor KPIs like setup time, waste, and rework to sustain improvements in DTF production efficiency.

Frequently Asked Questions

How does the DTF gangsheet builder improve the DTF gangsheet setup and streamline the DTF printing workflow?

The DTF gangsheet builder automates key prepress tasks—layout, color management, and automatic cut-path generation—transforming manual setup into a template-driven process. This tightens the DTF gangsheet setup, reduces errors, and accelerates the DTF printing workflow, boosting production efficiency and consistency.

In what ways does a DTF gangsheet builder enhance gangsheet cutting precision and overall production efficiency through automation?

By automatically generating precise cut lines and alignment marks that align with your hardware, the DTF gangsheet builder enhances gangsheet cutting precision and reduces waste from miscuts. The system standardizes templates and color separations, enabling smoother automation across jobs and improving DTF automation and overall production efficiency.

| Aspect | Key Points |

|---|---|

| Focus / Objective | Reduce setup time and streamline the DTF workflow using a gangsheet builder; improve layout accuracy, cut efficiency, and enable scalable production. |

| The Challenge |

|

| The Solution |

|

| Implementation Highlights |

|

| Benefits Realized |

|

| Best Practices |

|

| Common Pitfalls |

|

| Getting Started / Roadmap |

|

Summary

Conclusion: A DTF gangsheet builder can be a powerful catalyst for reducing setup time, improving the DTF printing workflow, and elevating production efficiency. By automating layout, color management, and cut-line generation, shops can transition from reactive prepress to a proactive, scalable process. The case study demonstrates that a well-implemented gangsheet builder doesn’t just shave minutes off a single step; it reshapes the entire production rhythm, enabling faster turnarounds, higher throughput, and more consistent results across jobs. For teams focused on quality and speed, embracing a gangsheet-driven workflow is a practical, data-driven path to sustainable improvement in DTF production.