DTF supplies for small businesses: Launch your tee line now

DTF supplies for small businesses are transforming how new apparel brands turn ideas into tangible products, enabling rapid prototyping and flexible production. DTF printing supplies deliver vibrant colors, a soft hand, and the cost efficiency to run small orders without the heavy upfront investments typical of older methods. To build momentum, learn how the transfer process works in practice and how a reliable flow of materials—from inks to films to powder—can stabilize your quality and margins. This guide outlines essential components and practical steps to set up a scalable system for launching a custom tee line. With a focus on accuracy, consistency, and a strong supplier network, you can move from concept to market quickly and confidently.

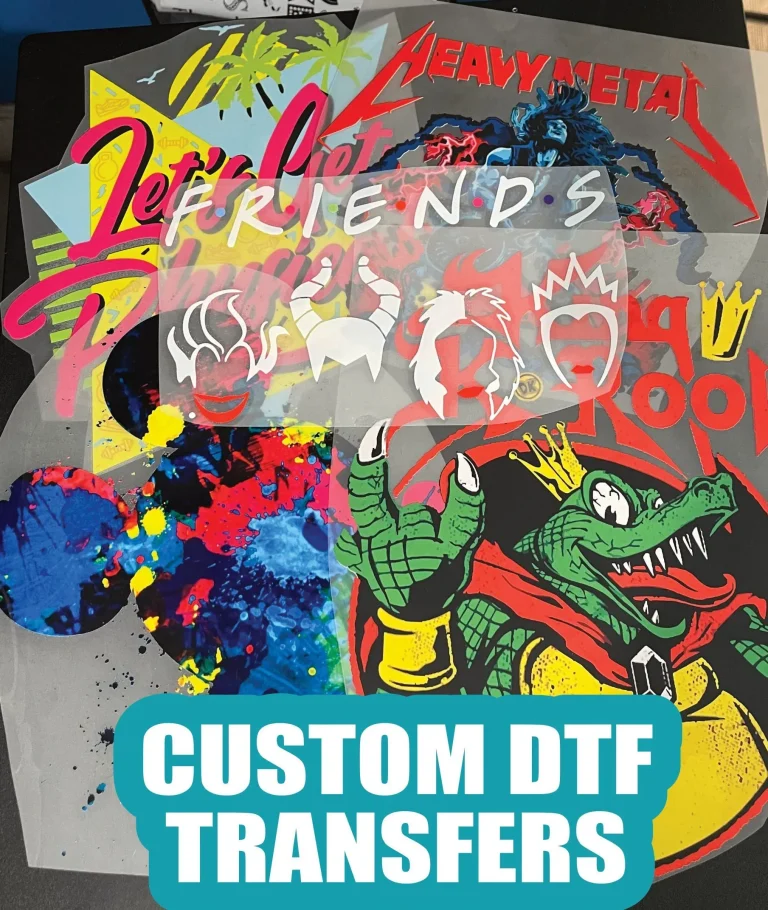

Viewed through an alternative lens, the same technology uses a coated transfer film and DTF transfers, a heat-activated adhesive to embed designs into textiles, a process often described as film-to-fabric transfers or adhesive-based printing. For small teams, this approach reduces inventory risk, supports on-demand production, and enables a wide color palette across garments. Setting up the right mix of supplies—coated transfer media, colorfast inks, and a reliable heat press workflow—helps maintain consistent output even as demand grows. In practice, planning around material compatibility, equipment upkeep, and regular quality checks ensures smooth scaling and brand consistency.

DTF supplies for small businesses: Building a scalable start to your custom tee line

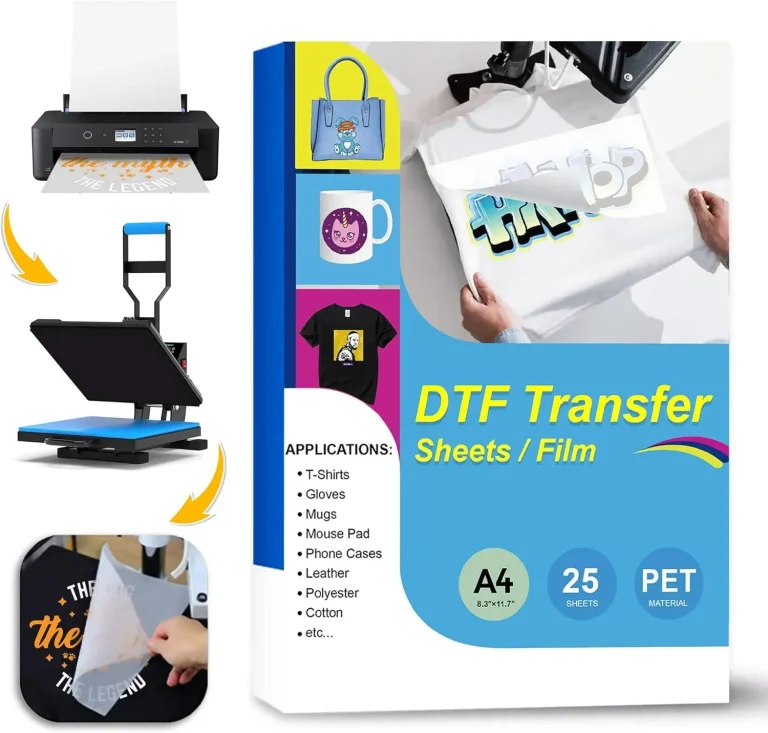

For aspiring apparel brands, DTF supplies for small businesses unlock a low‑risk path to start a custom tee line. By combining DTF printing supplies—a compatible printer, specialty transfer film, and water‑based inks—you can produce vibrant prints with a soft hand feel and minimal upfront inventory. The approach uses DTF transfers to apply designs on demand, enabling rapid testing and iteration that fits tight budgets and evolving customer preferences.

Choosing quality DTF printing supplies matters for consistent results. Look for reliable DTF ink and films that deliver bright color, strong adhesion, and wash durability. Evaluate color fidelity, bond strength, film clarity, and compatibility with your printer and heat press. With careful selection, you can keep per‑shirt costs predictable as you scale your small business t-shirt printing operations.

A practical workflow foundation helps you launch confidently: start with test shirts, calibrate color profiles, and maintain a clean production environment to minimize issues with powders, film dust, and residue. Establishing standard operating procedures for powder application, curing, and pressing time supports repeatable quality as your tee line grows.

Optimizing DTF transfers, inks, and films for durable designs in small business t-shirt printing

To deliver consistent results across runs, invest in solid DTF printing supplies and a color‑managed workflow. Begin with calibrated monitors, accurate color profiles, and lossless file formats to minimize color shifts from digital design to the transfer. Understanding how DTF transfers interact with DTF ink and films helps you predict vibrancy and edge detail across different fabrics.

Quality control and testing are essential for scalability. Run prints on multiple fabrics—cotton, blends, and performance textiles—to verify color stability and bond strength after washes. Regularly test feed consistency, powder application, and heat press settings to prevent misalignment, cracking, or peeling as you grow your custom tee line and expand into other items.

Efficiency and sustainability matter for profitability. Streamline prepress, minimize waste in powder usage, and optimize packaging to reduce costs and environmental impact. A disciplined approach to DTF transfers, inks, and films supports a durable product lineup and improves margins for your small business t-shirt printing venture.

Frequently Asked Questions

What are the essential DTF supplies for small business t-shirt printing?

Key DTF supplies for small business t-shirt printing include a DTF printer with compatible software, DTF transfer film, DTF inks, adhesive powder, and a reliable heat press. Add extra film rolls, powders, mixers, and test shirts to support a consistent workflow and quality control. Use these DTF printing supplies to achieve color-rich transfers with strong bond strength and wash durability. When evaluating suppliers, check color fidelity, film clarity, powder performance, and technical support to ensure reliable DTF transfers.

How can I start a custom tee line using DTF transfers and supplies for a small business?

Begin by defining your niche and brand story, then pilot a small catalog of designs printed with DTF transfers to test color, texture, and durability. Source reliable DTF inks, films, and adhesive powders, print sample tees on different fabrics, and gather feedback before a full launch. Build a simple workflow with color management, test shirts, and a soft launch to validate demand. This approach keeps costs manageable while you scale your custom tee line with DTF printing.

| Section | Key Points |

|---|---|

| Introduction / Overview |

|

| Understanding DTF printing basics |

|

| Core DTF supplies you need |

|

| Choosing quality DTF supplies |

|

| A practical plan to start a custom tee line |

|

| Workflow and color management for consistent results |

|

| Design, branding, and product mix |

|

| Quality control, troubleshooting, and maintenance |

|

| Cost considerations and return on investment |

|

| Sustainability and future growth |

|

Summary

DTF supplies for small businesses unlock an accessible path to launching a custom tee line with lower upfront costs and faster time to market. By selecting reliable DTF printing supplies, establishing a solid workflow, and prioritizing high quality designs and branding, you can build a compelling product line that resonates with your audience. Start by defining your niche, testing designs with small batches, and refining your process based on customer feedback. With the right mix of DTF supplies for small businesses, a thoughtful plan, and a customer-centered approach, your tee line can grow from a prototype into a thriving business.