California DTF: Complete Guide to Direct-to-Film Printing

California DTF has emerged as a hot topic for apparel brands, screen printers, and DIY crafters across the Golden State. Direct-to-Film printing delivers color vibrancy, durability, and versatility, making it a practical choice for small shops and larger studios alike. DTF printing in California is supported by accessible suppliers and regional equipment options, which helps streamline the DTF transfer process. With the right DTF printer setup and workflow, designers can expand garment options without the long prep times of other methods, including DTF vs screen printing. If you’re evaluating methods for a California-based brand, this introductory guide highlights what to expect, from equipment and costs to practical tips for getting started.

Beyond the shorthand of DTF, many suppliers describe this as film-based transfer technology that uses printed PET sheets and heat-activated adhesives. This on-demand garment transfer workflow bridges the gap between traditional screen printing and DTG, emphasizing short runs and customization. In practice, shops discuss the same process under terms like adhesive-transfer film and pigment-based heat transfers, focusing on color fidelity and fabric compatibility. Using LSI-friendly language helps readers relate the concept to related equipment, software workflows, and testing protocols used by California shops.

California DTF: A Practical Guide to Direct-to-Film Printing in the Golden State

Direct-to-Film printing has become a practical option for California brands, offering vibrant color, durable results, and flexibility for small shops and larger print houses alike. Direct-to-Film printing (DTF) uses water-based inks on a PET film, followed by an adhesive powder that is cured before transfer. When pressed onto fabric with moderate heat and pressure, the result is a flexible, high-contrast graphic that adheres well to cotton, blends, and even polyester. This Descriptive overview explains how DTF fits into a California workflow, including the basic equipment, typical costs, and a practical starting point for new users.

For California businesses, the buying ecosystem—local suppliers, regional heat presses, and training resources—helps shops reduce lead times and improve consistency. A sensible DTF setup can begin with a proven printer, the right PET film, powder, curing device, and a reliable heat press. Ongoing considerations include ink costs, RIP software, calibration, and maintenance. By focusing on predictable color management, routine testing, and efficient cleaning, California operators can build a scalable DTF operation that serves on-demand orders and small-batch runs with confidence.

DTF Transfer Process Demystified: From Film to Fabric

The DTF transfer process starts with artwork prepared in your design software and then printed onto PET film using water-based inks. After printing, adhesive powder is dusted evenly over the ink and cured to create a bonding layer. The film is then pre-heated and aligned on the garment before transferring under heat and pressure. Whether you’re printing on cotton, blends, or synthetics, this sequence delivers a vivid, durable image that remains flexible after washing.

Quality control is essential: ensure proper white underbase where required, verify color separation, and test on representative fabrics. Calibrating your RIP and ICC profiles helps maintain consistency across batches, especially when you’re serving multiple California customers with varying garment types. The process hinges on reliable film, correct powder coverage, and precise heat timing to prevent issues like crinkling or flaking during the transfer.

DTF Printer Setup for California Shops: Getting Started Right

Starting right with DTF printer setup means selecting a dependable printer that handles water-based inks well and offers solid gray balance and color accuracy. Pair this with compatible PET film, adhesive powder, and a robust curing station. An effective setup also includes RIP software and color-management workflows that produce predictable results. In a California context, a well-planned printer setup reduces surprises during busy periods and supports consistent reprints across orders.

Maintenance and workflow discipline matter as much as hardware. Keep rollers and print paths clean to prevent head clogs and film jams, and establish a regular preventive maintenance schedule. Document heat press settings, dwell times, and pre-press procedures so teams can reproduce results quickly. By investing in routine calibration, firmware updates, and supplier support, a California shop can sustain high-quality DTF output with minimal downtime.

DTF Printing in California: Market Trends and Local Opportunities

California’s apparel market spans surf, streetwear, event merchandise, and on-demand fashion. DTF printing in California enables fast turnarounds, lower minimums, and customization that appeals to local brands and retailers. With printable color depth, the ability to print vivid multi-color designs on a broad range of fabrics, and straightforward post-processing, DTF aligns with California’s demand for flexible production and short-run capability.

Local opportunities include proximity to suppliers, regional heat presses, and access to training and peer networks. Shops can partner with California-based distributors for DTF film, powders, and inks, streamlining the supply chain and reducing shipping time. Training programs and community resources help new entrants learn the DTF transfer process quickly, enabling startups and indie brands to compete with established shops while maintaining fast turnarounds.

DTF vs Screen Printing: Choosing the Best Path for Small Runs and Custom Orders

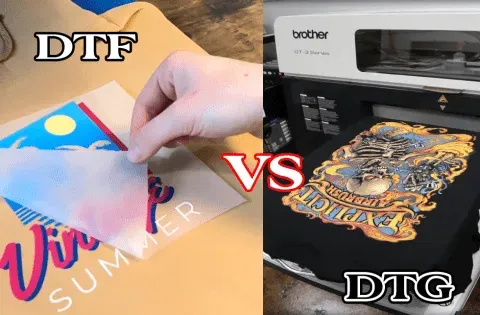

When deciding between DTF and screen printing, the choice often comes down to run length, setup time, and design complexity. DTF vs screen printing offers a compelling advantage for small runs and highly customized orders, thanks to minimal setup and no need for screens. In California, where speed to market matters, DTF lets you deliver personalized designs with quick turnarounds without the upfront tooling required for traditional screens.

However, screen printing remains strong for large volumes with repeat designs, where per-unit costs drop and ink coverage is predictable. DTF shines on dark fabrics and intricate color work, delivering full-color art with fewer production steps and less waste. Understanding the trade-offs helps California shops tailor their offerings to customers who demand variety, durability, and fast delivery.

Optimizing Color, Quality, and Compliance: Color Management for DTF in California

Color management starts with calibrated hardware, reliable ICC profiles, and RIP settings that reproduce consistent hues across runs. Use the printer’s color engine in conjunction with ICC targets to maintain gray balance, saturation, and accurate skin tones, especially when serving California clients with diverse garment palettes. Regular proofing and test prints on common fabrics help ensure predictable results in real-world orders.

Safety, sustainability, and compliance matter in California workshops. Choose water-based inks when possible and follow powder and film disposal guidelines to minimize environmental impact. Proper ventilation, dust control, and a documented maintenance routine protect workers and equipment. By aligning with local regulations and adopting responsible practices, California DTF operations can scale confidently while delivering high-quality, compliant products.

Frequently Asked Questions

What is California DTF (Direct-to-Film printing) and how does the DTF transfer process work?

California DTF refers to Direct-to-Film printing used in the Golden State. In this process, designs are printed on a PET film with water-based inks, adhesive powder is applied and cured, and the resulting sheet is transferred to fabric with a heat press. The DTF transfer process yields vibrant, durable graphics across a range of fabrics.

How does DTF printing in California compare to screen printing for small runs?

DTF printing in California is typically more cost-effective for short runs due to low setup costs and no screens. It offers fast turnaround and easy customization, which suits small-batch orders. For high-volume production, traditional screen printing may offer lower per-unit costs.

What should I consider for a DTF printer setup in California?

When planning a DTF printer setup in California, select a reliable DTF printer, appropriate PET film, adhesive powders, and a curing/heat-press system. Also plan for inks, RIP software with proper ICC profiles, and local support or training. Test across your most common California fabrics to ensure consistent results.

What is the DTF transfer process and what should California shops know?

The DTF transfer process involves printing on DTF film, applying and curing adhesive powder, pre-heating the garment, and transferring the design with heat and pressure. California shops should ensure proper powder curing, even heat application, and suitable fabric handling for reliable adhesion across orders.

What are common challenges with California DTF and how can I troubleshoot?

Common challenges include powder not adhering, white underbase issues, fabric compatibility, and color shifts. Troubleshooting steps include confirming cure time/temperature, ensuring even powder coverage, recalibrating the printer and RIP, and testing across the fabrics you serve in California.

Is DTF the right choice for high-volume production in California, or is DTF vs screen printing better for large runs?

DTF can support on-demand and short to moderate runs in California with quick turnarounds and customization, improving ROI for many shops. For very large volumes with repeated designs, screen printing may offer lower per-unit costs, so weighing DTF vs screen printing is important for planning in California.

| Aspect | Key Point | California DTF Context |

|---|---|---|

| What is Direct-to-Film (DTF)? | DTF prints designs on PET film using water-based inks, applies an adhesive powder, cures, and then transfers the design to fabric with a heat press to produce a durable, vivid graphic. | Used by CA shops to enable vibrant, on-demand printing across cotton, blends, and polyester; aligns with local suppliers, heat presses, and training resources. |

| Why DTF in California | Strong demand in surf/streetwear and event merchandise; cost-effective for short runs; faster setup than screen printing. | California shops leverage quick turnarounds, smaller minimums, proximity to suppliers and training resources. |

| Key equipment & materials | DTF printer; PET film; adhesive powder; curing station/heat gun; hot press or conveyor dryer; inks and RIP software; cleaning and maintenance supplies | Choose equipment that integrates with California workflows and training; prioritize reliability, color accuracy, and support networks locally. |

| Typical workflow in California | Artwork prep → print on film → apply and cure adhesive powder → pre-press garment → transfer to fabric → post-press finishing | Consistent color, adhesion, and heat application are essential for CA shops serving diverse fabrics and orders. |

| DTF vs other methods (summary) | DTF vs Screen: cost-effective for small runs; Screen better for large volumes. DTf vs HTV: more durable, softer hand, handles complex color. DTF vs DTG: better ink coverage on dark fabrics; vivid color across materials. | In California, DTF enables customization and rapid iteration alongside traditional methods; supports on-demand production. |

| Quality control & color management | Calibrate printer; use ICC profiles; profile RIP software; test on common fabrics (cotton, blends, synthetics) | California fabrics vary; test and profile for consistent results across CA customer bases. |

| Cost considerations & ROI | Initial investment: several thousand to over ten thousand; ongoing costs for inks, films, powders; ROI from fast turnarounds and customization | CA shops can capitalize on local demand from brands, vendors, and events; ROI improves with service-level advantages. |

| Common challenges & troubleshooting | Powder adhesion issues; white underbase issues; cracking/adhesion on certain fabrics; color shifts; address by adjusting cure/heat, powder distribution, and fabric testing | Proactive testing on common California fabrics helps minimize downtime and returns. |

| Safety, sustainability & compliance | Ventilation; proper disposal of powders/films; prefer water-based inks; follow manufacturer guidelines; comply with California regulations | Safe, compliant CA workshops reduce risk and support long-term operation in the state. |

| Future trends in California DTF | Higher efficiency, better color accuracy, greener materials; more training/resources in CA; ongoing innovations in powders/films | California market is poised for continued adoption, with growing training networks and sustainability-focused improvements. |

Summary

California DTF offers a flexible, cost-effective path for producing vibrant, durable prints across a range of fabrics and orders. By understanding the Direct-to-Film process, selecting the right equipment and materials, and embracing color management and quality control, California shops can deliver consistently excellent results. Whether serving local brands in the Golden State or launching on-demand product lines, California DTF provides a scalable solution that aligns with California’s fast-paced, creative economy. Embrace the opportunities of California DTF to meet the growing demand for high-quality, customized apparel in the years ahead.