DTF Gangsheet Builder: Pro Tips for Layout, Bleeds, Spacing

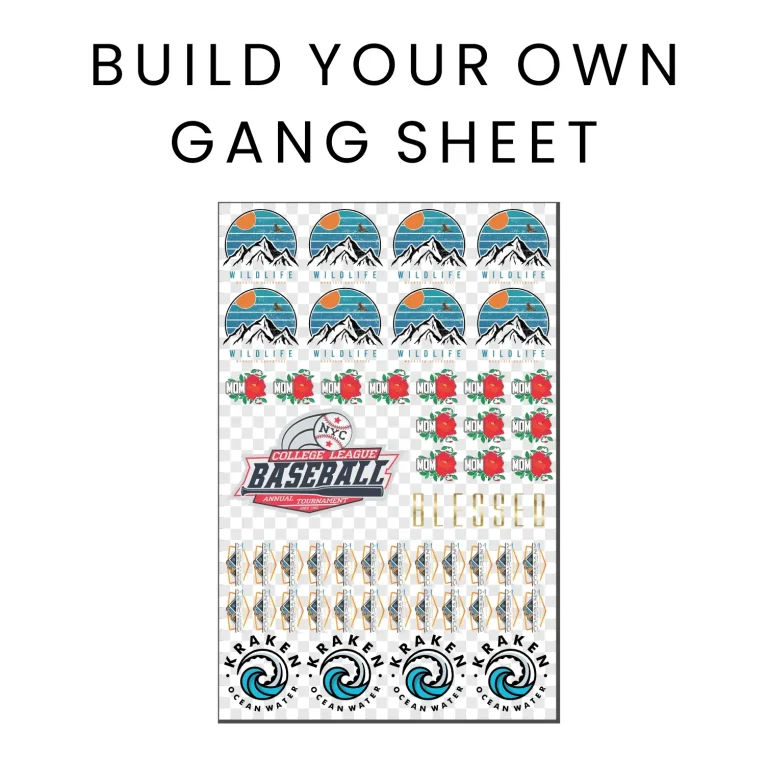

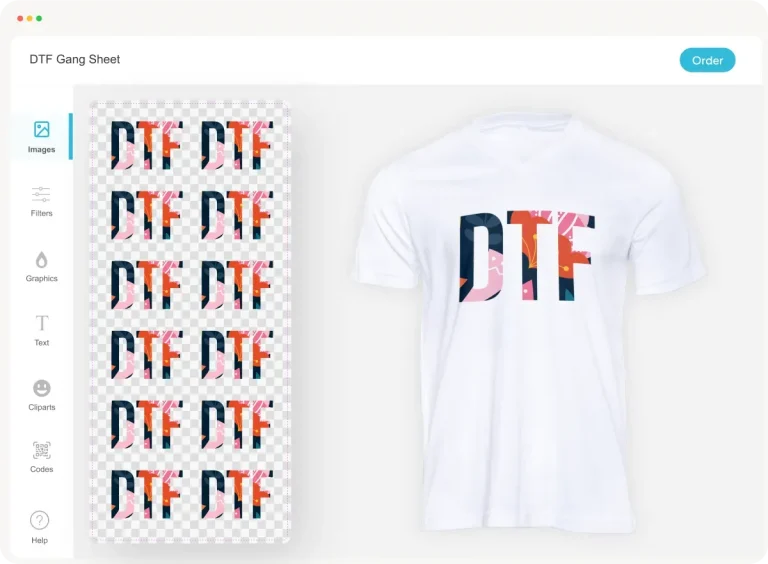

DTF Gangsheet Builder is transforming how printers assemble multiple designs on a single transfer sheet for direct-to-film production. By optimizing layout, managing bleeds and spacing, and supporting layout optimization for print-ready gang sheets, this tool helps teams cut setup time and reduce waste. On every project, it supports precise placement, color consistency, and repeatable results across runs. Users can leverage gangsheet design tips to maximize throughput while safeguarding artwork integrity in DTF printing. From templating to prepress checks, the platform guides operators toward efficient, high-quality outputs.

Seen through an LSI perspective, this concept becomes a scalable workflow for combining multiple designs onto a single transfer sheet. Other terms you might encounter include a gangsheet creation tool, a multi-design layout solution, or a print-layout optimizer. This approach emphasizes consistent tiling, reliable margins, and predictable trimming, all essential for efficient textile production. By focusing on transferable ideas like bleed control, spacing discipline, and color alignment, teams can reason about outcomes without tying themselves to a single product name. Ultimately, adopting a flexible, template-driven process helps printers speed up setup, reduce waste, and deliver uniform results across runs.

DTF Gangsheet Builder: Mastering Layout Optimization for Print-Ready Gang Sheets

Using the DTF Gangsheet Builder shifts how you plan every design on a transfer sheet. It’s more than a tool—it’s a method for grouping designs, sizing tiles to the printer’s printable area, and aligning elements with precision. By embracing a grid-based approach and standardized margins, you can boost production efficiency, maintain consistent color placement, and reduce waste. This disciplined approach underpins print-ready gang sheets and is the core advantage of DTF printing workflows that rely on layout optimization to produce reliable, repeatable results across runs.

To implement effectively, start with a master template that includes grid lines, margins, bleed areas, corner marks, and export presets. Preflight regularly (DPI 300–600, color profiles, and embedded targets) and keep a versioned library of gangsheet designs that track changes to margins, bleeds, and spacing. Predefine alignment cues and safe zones to ensure designs are easy to position during transfer, which is exactly how gangsheet design tips translate into real-world gains in speed and accuracy.

Bleeds, Spacing, and Quality Assurance in DTF Printing: Tips for Print-Ready Gang Sheets

Bleeds and spacing are the invisible levers that separate professional results from misprints in DTF printing. A typical bleed of 2–3 mm beyond the trim edge helps garments print cleanly when trims aren’t perfectly aligned, and you may push to 3 mm for gradients near edges. Establish consistent spacing between adjacent designs—4–6 mm, or 6–8 mm for high-precision runs—to prevent ink smearing and transfer bleed. Also define trim margins and safe zones so important logos stay inside the safe area while decorative elements can extend to bleed zones.

Beyond the artwork, a strong QA workflow ensures outcomes match expectation. Implement preflight checks for DPI, color management (proofing with on-garment swatches), and consistent export settings (print-ready gang sheets, PDF or TIFF with embedded profiles). Use automated checks where possible, maintain a version-controlled template library, and run small test sheets to validate alignment, color accuracy, and bleed integrity before committing to large batches. These gangsheet design tips support a robust, repeatable DTF printing process.

Frequently Asked Questions

How does the DTF Gangsheet Builder enhance layout optimization for DTF printing?

The DTF Gangsheet Builder streamlines grouping multiple designs on a single sheet using a grid-based template with standardized margins and alignment cues. This layout optimization reduces setup time, minimizes waste, and ensures consistent color placement across runs, producing print-ready gang sheets with reliable bleeds and spacing. Benefits include improved production efficiency, better prepress control (DPI and color profiles), and repeatable results across batches.

What are essential gangsheet design tips for managing bleeds and spacing when using the DTF Gangsheet Builder?

Key tips include: – Bleeds: use 2–3 mm bleeds, up to 3 mm for gradients to prevent edge exposure. – Spacing: maintain 4–6 mm between designs (6–8 mm for high-precision work) to avoid transfer bleed. – Trim marks and safe zones: include marks and keep critical elements inside the safe area. – Substrate considerations: account for fabric variability with margins and guides. – Templates: use print-ready templates that embed bleed and spacing rules to ensure consistent results across runs.

| Topic | Key Points | Why It Matters |

|---|---|---|

| What is the DTF Gangsheet Builder | A toolkit to group multiple designs on one transfer sheet with precision, covering layout, bleeds, spacing, DPI checks, and export targets. | Creates a consistent, efficient workflow and reduces errors across runs. |

| Layout Optimization | Use a grid system, define max printable area, set alignment cues, consider substrate variability, and plan ink coverage. | Maximizes sheet usage, ensures uniform spacing, and minimizes reprints. |

| Bleeds and Spacing | Bleed typically 2–3 mm beyond trim; spacing between designs 4–6 mm (6–8 mm for high-precision); include trim marks and safe zones; manage color near bleeds. | Prevents white edges, color bleed, and misalignment after trimming. |

| Practical Workflow | Standardized templates, preflight DPI/color profiles, consistent export, test runs, and version control. | Supports repeatable results, easier auditing, and scalable production. |

| Common Pitfalls | Inconsistent DPI, overlapping bleeds, misaligned trims, substrate behavior, and color mismatches. | Helps teams anticipate and prevent costly reprints. |

| Advanced Tips | Automate placements, use color-aware templates, digital proof workflows, and QA checklists. | Increases throughput and maintains consistent quality. |

| Case Study | Standardized templates with fixed margins, bleed zones, and spacing reduced setup time by 25% and waste by 18% across lines. | Demonstrates real-world impact and value. |

Summary

The table above summarizes the core concepts of the DTF Gangsheet Builder, emphasizing layout optimization, bleed and spacing management, and a practical workflow to improve production efficiency and print quality. By following pro tips and avoiding common pitfalls, teams can achieve consistent results across multiple designs on gang sheets.