DTF Inks: What You Need to Know for Optimal Printing

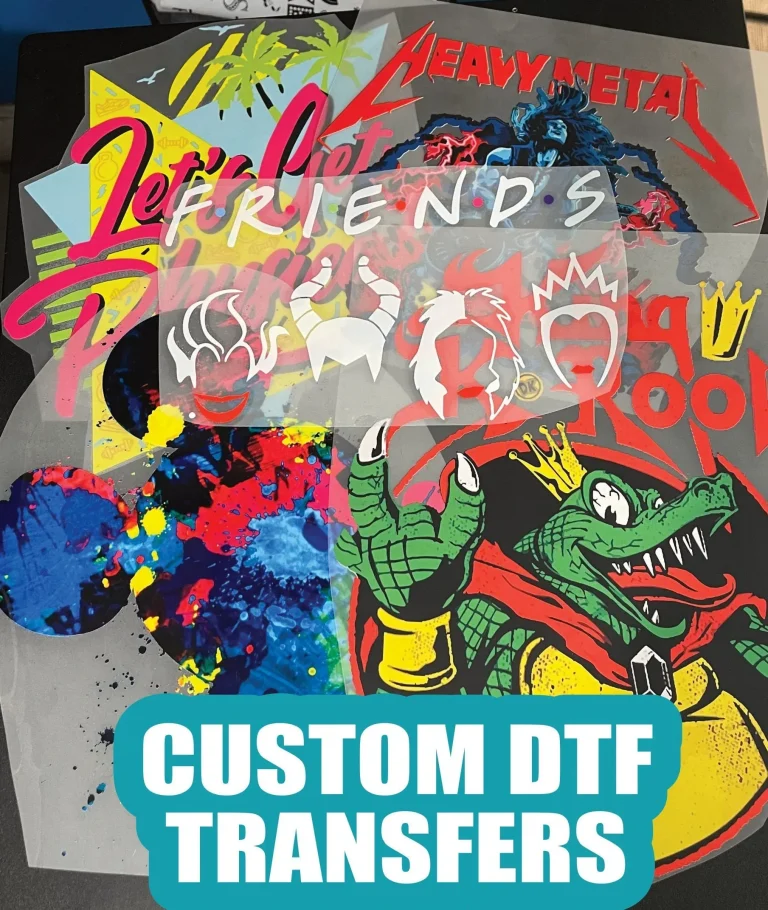

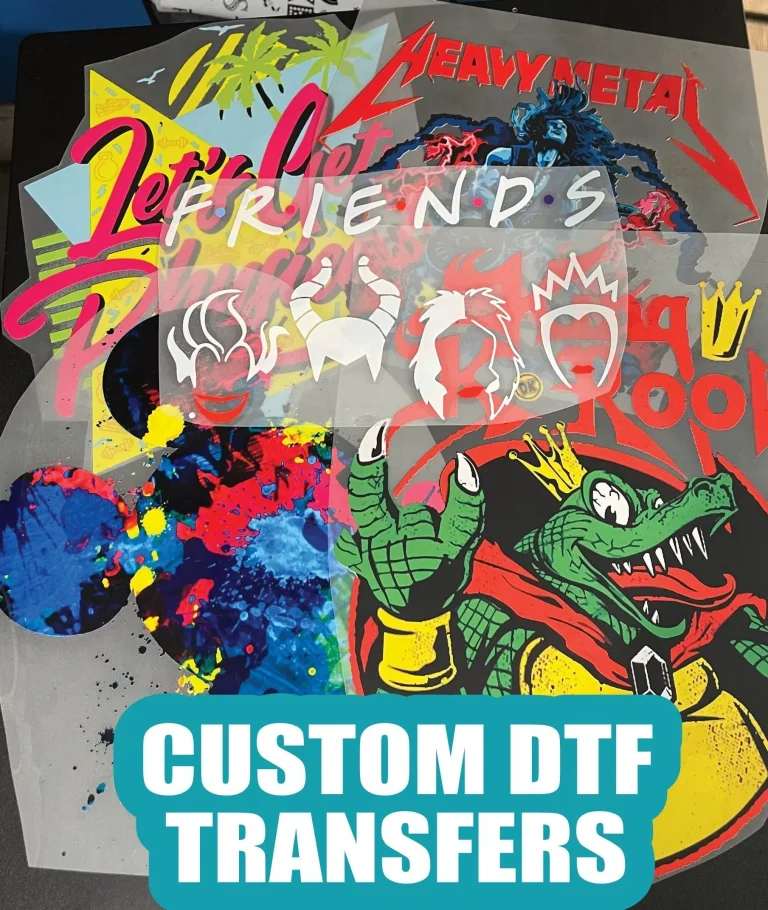

DTF inks, or Direct to Film inks, are revolutionizing the textile printing industry with their ability to produce vibrant, detailed designs on a variety of fabrics. This innovative printing method harnesses the benefits of DTF printing techniques, allowing for high-quality outputs that meet the growing demand for custom apparel. With the rise of eco-friendly DTF inks, businesses can now enjoy sustainable printing solutions without compromising on quality. The advantages of DTF printing include not only exceptional color vibrancy and wash resistance but also a cost-effective printing process, making it an appealing choice for companies of any size. As more businesses turn towards this adaptable technology, understanding the ins and outs of DTF inks becomes essential for thriving in a competitive marketplace.

When discussing the world of Direct to Film printing, it’s important to explore the various facets that make it a game-changer in the textile industry. These specialized inks offer an impressive array of benefits, catering to the needs of businesses seeking high-quality, customizable solutions. Using terms like film-based printing and polyester transfer inks, we can delve into the various DTF printing advantages while prioritizing eco-friendly practices. Companies can leverage the cost-efficient and vibrant outputs provided by these innovative inks to create a lasting impression in the market, ensuring they stay relevant among consumers. By mastering DTF printing techniques, businesses can optimize their operations and enhance their product offerings.

Understanding DTF Inks and Their Significance

DTF inks are a revolutionary advancement in the realm of textile printing. Designed explicitly for Direct to Film printing, these inks are formulated to provide vibrant colors and intricate designs on a wide range of fabrics. The process involves printing the designs onto a specially coated transfer film, which is then used to apply the ink onto the fabric using heat. This method not only enhances color vibrancy but also allows for high-resolution images that can retain their clarity even after multiple washes. As businesses compete for consumer attention, the significance of DTF inks cannot be overstated, making them a favored choice in the ever-evolving world of custom apparel.

Moreover, DTF inks offer a level of versatility that appeals to a variety of businesses, from small startups to larger enterprises. Unlike traditional printing methods such as Direct to Garment (DTG) or screen printing, DTF printing eliminates the need for extensive setup, allowing for quicker production times and greater flexibility. This adaptability makes it an ideal solution for custom orders, where designs can vary significantly from one piece to another without affecting overall production efficiency.

Frequently Asked Questions

What are DTF inks and how do they work in Direct to Film printing?

DTF inks are specially formulated inks used in the Direct to Film (DTF) printing process, where designs are printed onto a transfer film and then heat-pressed onto various fabrics. This method allows for vibrant colors and intricate details, making it a popular choice for custom apparel.

What are the advantages of DTF printing compared to other printing methods?

DTF printing offers several advantages, including cost-effectiveness for bulk orders, improved color vibrancy, and better wash resistance compared to other methods like Direct to Garment (DTG) printing. The technology also ensures quicker production times, meeting customer demands efficiently.

Are there eco-friendly DTF inks available for sustainable printing?

Yes, many manufacturers now provide eco-friendly DTF inks formulated with water-based components. These inks reduce harmful emissions during printing and comply with strict environmental regulations, catering to the growing market demand for sustainable textile printing solutions.

What DTF printing techniques are essential for optimal results?

To achieve optimal results in DTF printing, it is essential to use proper ink settings based on fabric type, control curing temperatures and times accurately, and select the right transfer films. Practicing these techniques will help improve print quality and durability.

How cost-effective is DTF printing for businesses?

DTF printing is highly cost-effective, especially for bulk production runs, resulting in a lower cost per unit compared to other methods like DTG. The rapid production capabilities also enhance efficiency, making it an excellent choice for businesses of all sizes.

What should I consider when choosing DTF printing equipment?

When selecting DTF printing equipment, consider affordability and user-friendliness. Today’s printers come at various price points and often include features that simplify the printing process, enabling even beginners to produce high-quality results.

| Key Points | |

|---|---|

| What Are DTF Inks? | DTF inks are specially formulated inks for Direct to Film printing, transferring vibrant images onto fabrics. |

| Quality and Performance | DTF inks provide improved color vibrancy, adhesion, and wash resistance, ensuring long-lasting prints. |

| Environmental Considerations | Eco-friendly DTF inks reduce harmful emissions and align with sustainability goals in textile printing. |

| Cost Efficiency | DTF printing offers lower costs for bulk orders and quick production times compared to other methods. |

| Equipment and Technology | Affordable DTF printers are now available, making the technology accessible to all types of businesses. |

| Techniques for Successful Printing | Proper ink settings, temperature control, and film selection are crucial for optimal DTF printing results. |

| Market Growth and Future Trends | The DTF printing market is growing, driven by demand for custom apparel and innovations in printing technology. |

Summary

DTF inks are transforming the textile printing landscape, enabling businesses to achieve high-quality prints with vibrant colors and impressive durability. As the market for custom printing expands, DTF inks provide a sustainable and cost-effective solution that cater to the needs of modern consumers. With continual advancements in ink formulations and printing technologies, those in the industry can leverage these developments to enhance their printing operations and meet customer expectations. Embracing DTF inks not only improves printing capabilities but also aligns businesses with evolving market trends, ensuring they remain competitive in a dynamic environment.