DTF Printing vs. DTG: Key Differences Explained

DTF printing, or Direct-to-Film printing, is revolutionizing the way custom garment printing is approached, offering an innovative solution for diverse fabric types. This cutting-edge printing technology allows for vibrant designs that can be efficiently transferred onto a broad range of textiles, including cotton and polyester blends. As artists and entrepreneurs embrace DTF printing, the conversation shifts towards understanding its distinct advantages over other methods, notably DTG printing. In comparing DTF vs DTG, one can appreciate the unique characteristics that cater to different market demands, especially as the fabric printing landscape evolves. This guide delves into the essential differences between these printing methods, enabling you to make an informed choice for your creative projects.

Exploring the realm of innovative fabric printing techniques, Direct-to-Film (DTF) emerges as a standout option in custom garment printing. As businesses and creatives seek high-quality products tailored to specific client needs, understanding the capabilities of DTF alongside its counterpart, Direct-to-Garment (DTG), becomes essential. Both methods utilize advanced printing technology to deliver stunning visuals, yet they cater to different aspects of the printing process. DTF offers greater versatility in fabric compatibility and production efficiency, making it a favored choice for larger projects. This article aims to shed light on the critical elements that distinguish these two printing methodologies, guiding users toward the most suitable option for their ventures.

Understanding DTF Printing: A Modern Solution for Custom Apparel

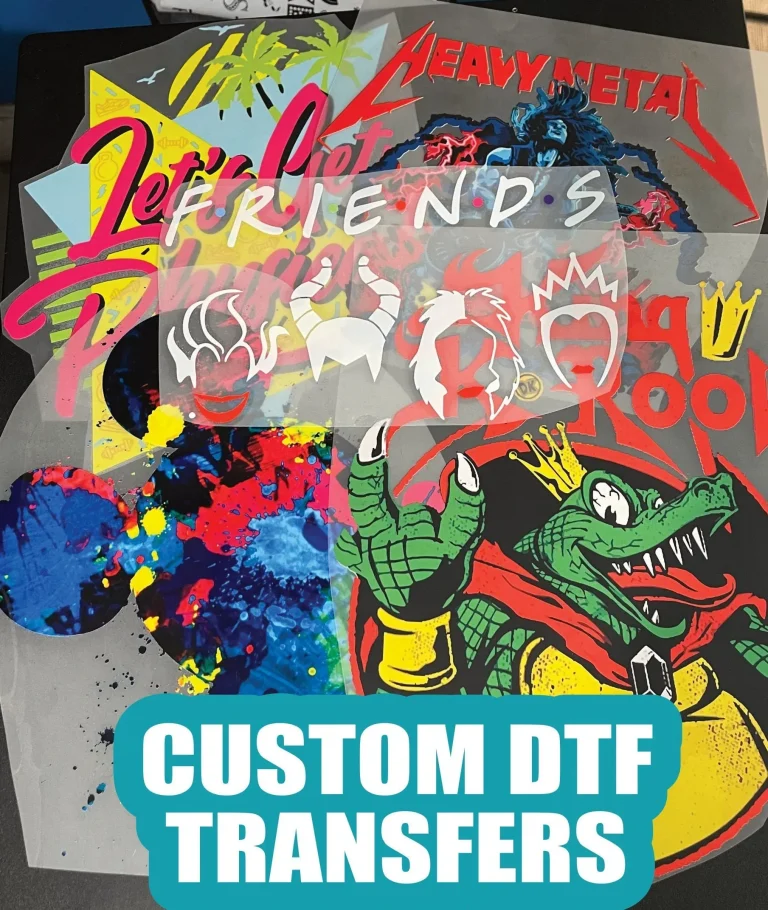

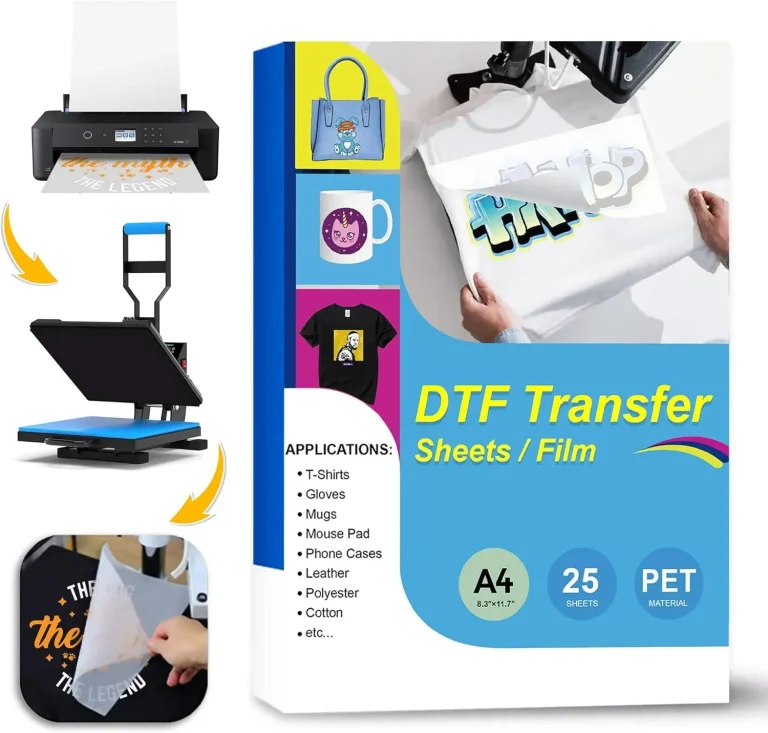

DTF printing, or Direct-to-Film printing, is swiftly gaining popularity as a method of custom garment printing that combines efficiency with versatility. By transferring designs from a specialized film directly onto textiles, DTF allows for vibrant and detailed prints without the severe limitations of fabric type that some traditional methods impose. This technology employs a heat transfer process that can effectively work on a variety of materials, such as cotton, polyester, and blends, making it a go-to choice for businesses that require flexibility.

The process begins with printing the design onto a special film, after which a heat application adheres the graphics to the garment. The result is a durable and vibrant print that maintains its quality through numerous washes, making it particularly appealing for fashion brands and promotional items. As well, DTF printing is becoming known for its ability to yield consistent quality over larger runs, making it an efficient option for any business looking to scale its custom garment production.

Comparing DTF and DTG: Key Advantages and Disadvantages

When comparing DTF and DTG printing methods, it’s crucial to identify their specific advantages and disadvantages in different contexts. For instance, while DTG printing excels in producing high-resolution, detail-rich images directly onto fabrics, it is limited primarily to cotton-based materials and can be slower in production speed. This makes DTG ideal for small batch orders or individual customized pieces, but less suitable for larger production runs.

Conversely, DTF printing boasts superior versatility, being applicable to a wider range of fabrics, including synthetic blends and darker materials. The ability to produce transfers in bulk and apply them to garments quickly enhances production speed significantly, a factor that is especially beneficial for businesses focusing on volume. However, the initial setup for DTF can require expertise in managing the heat application process, which could pose a learning curve for newcomers to the printing industry.

Fabric Compatibility: DTF vs. DTG

Fabric compatibility is a critical consideration when choosing between DTF and DTG printing technologies. DTG printing thrives on 100% cotton fabrics, specifically light-colored garments, where it can deliver stunning photo-realistic prints. However, this limitation can hamper options when brands want to expand their offerings to a wider fabric range or cater to bulk orders with varied fabric types.

DTF printing, on the other hand, stands out due to its compatibility with multiple fabric types including cotton, polyester, and various blends. This adaptability allows for customized printing options on a diverse selection of garments, from sportswear to fashion items. Businesses looking to diversify their product lines can benefit from the capabilities of DTF, as it meets the demands for more varied fabric choices without sacrificing print quality.

Durability of DTF and DTG Prints: What to Expect

Durability is a significant factor when evaluating the efficacy of printing methods for garments. DTG prints are often characterized by a soft feel and direct adherence to fabric. However, over time and through frequent washing, these prints may experience fading or wear. This limitation is important for product longevity, especially for garments intended for long-term use.

In contrast, DTF printing techniques have been noted for their remarkable durability. The heat transfer process creates a strong bond with the fabric that resists fading, cracking, or peeling even after many washes. The prints maintain vibrancy longer, making DTF an optimal choice for high-demand garments or promotional items that require robust durability in their design.

Production Speed: Evaluating Efficiency in Printing

Production speed is a key differentiator between DTF and DTG printing technologies. DTG printing often involves a meticulous setup process, which can slow down production, especially when printing multiple items. While this method excels in producing detailed prints, it is less efficient for larger scale projects, which can affect turnaround times in a business context.

DTF printing outshines in terms of efficiency, as it allows for multiple transfers to be printed simultaneously. Afterward, the application of these transfers can zip through the production process, enabling businesses to fulfill larger orders in less time. This feature makes DTF particularly attractive for companies seeking to streamline operations without compromising on print quality.

Making the Right Choice: DTF vs. DTG for Your Needs

Choosing the appropriate printing method between DTF and DTG boils down to various factors such as the target market, the complexity of the designs, and fabric types. For instance, brands aiming at a market that values custom, intricate designs may lean toward DTG due to its unparalleled ability to reproduce fine details. However, businesses primarily focusing on bulk orders or diverse fabric specifications might find DTF printing to be more advantageous.

Ultimately, assessing your business needs and print objectives is crucial in making this decision. Factors like production speed, cost-effectiveness, and durability will shape the most fitting choice for establishing a successful custom garment printing line. Both DTF and DTG offer valuable benefits, and understanding their unique features and best-use scenarios will help ensure your printing endeavors resonate well with your customer base.

Frequently Asked Questions

What is DTF printing and how does it differ from DTG printing?

DTF printing, or Direct-to-Film printing, uses a specialized film to transfer designs onto fabric, making it versatile for various materials including cotton, polyester, and blends. It differs from DTG printing, where designs are directly applied to garments, typically excelling only on 100% cotton fabrics.

What are the key benefits of using DTF printing for custom garment printing?

DTF printing is beneficial for custom garment printing due to its compatibility with multiple fabric types, impressive durability, and faster production speed, making it ideal for large orders and varied projects compared to DTG printing.

Can DTF printing be used on dark fabrics like DTG printing?

Yes, DTF printing can effectively print on dark fabrics, unlike DTG printing which is generally limited to lighter tones. DTF’s heat transfer process allows for vibrant designs on any fabric color.

How does the durability of DTF printing compare to DTG printing?

DTF printing is known for its outstanding durability, maintaining vibrant colors through numerous washes, while DTG prints can fade over time, particularly under harsh washing conditions.

What are the cost considerations when choosing between DTF and DTG printing?

DTF printing typically has a lower initial investment and more affordable ongoing costs compared to DTG printing, which has higher upfront and maintenance costs due to specialized equipment and inks.

Is DTF printing an environmentally friendly option compared to DTG printing?

While DTG printing often uses eco-friendly water-based inks, advancements in DTF technology are improving its sustainability. However, DTF historically faced criticism for its environmental impact compared to DTG.

| Feature | DTG Printing | DTF Printing |

|---|---|---|

| Process Overview | Uses inkjet technology to print directly onto fabric, ideal for detailed designs on cotton. | Prints designs onto film first and then transfers onto fabric, versatile for various materials. |

| Fabric Compatibility | Best for 100% cotton and light-colored fabrics. | Works well on cotton, polyester, blends, and more. |

| Print Durability | Soft prints can fade over time, especially with harsh washing. | Highly durable prints that withstand many washes without fading. |

| Production Speed | Typically slower with longer setup times, less efficient for large orders. | Faster production with ability to print transfers in bulk. |

| Cost Considerations | Higher initial investment and maintenance costs. | Lower initial costs and more affordable operating expenses. |

| Environmental Impact | Uses water-based inks, generally more eco-friendly. | Has historical environmental criticisms, but improving ink formulas. |

Summary

DTF Printing offers a versatile and efficient solution for businesses and individuals looking to create custom apparel. By comparing the nuances of DTF and DTG printing, it’s evident that each method serves distinct needs within the textile industry. DTF excels in fabric compatibility and production speed, making it ideal for bulk orders and diverse material requirements, whereas DTG provides superior quality for detailed designs on cotton. As the landscape of garment printing continues to evolve, understanding the strengths of DTF Printing will empower you to make informed choices, ensuring you meet your unique printing demands while maximizing quality and efficiency.