DTF Transfers: The Ultimate Step-by-Step Tutorial

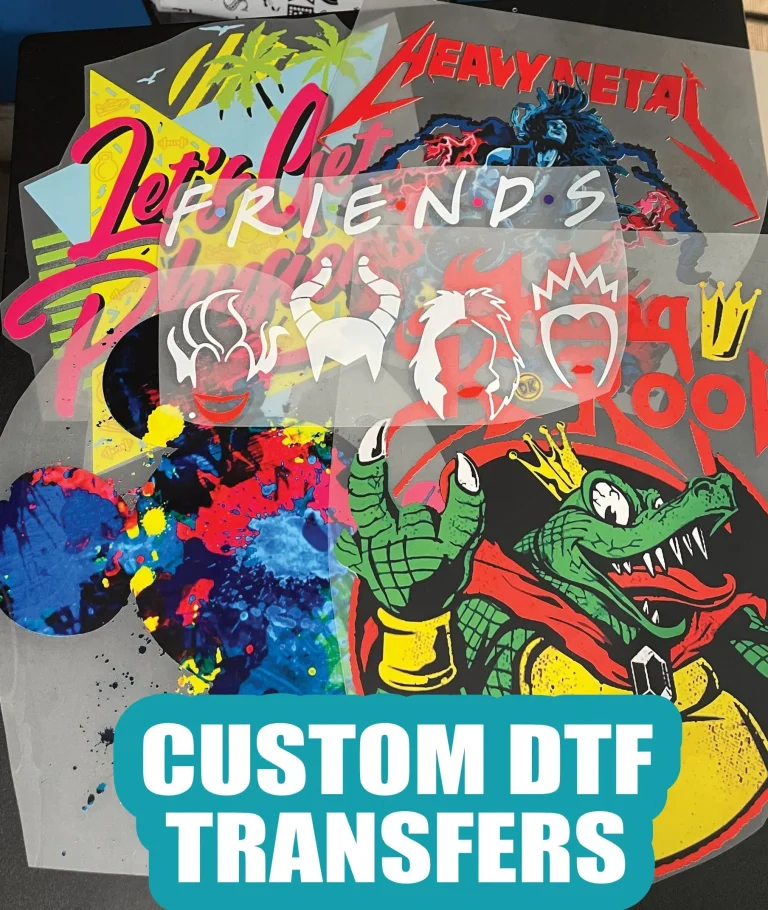

DTF transfers, or Direct-to-Film transfers, are transforming the landscape of custom textile printing by enabling vibrant, high-quality designs to be effortlessly applied to a variety of fabrics. This innovative printing method utilizes specialized films that allow for rich color vibrancy and exceptional durability, making it a preferred choice among garment creators. In our comprehensive DTF printing tutorial, we’ll explore the essential DTF printing materials needed for successful application, ranging from the right printer to the heat press transfer that binds your designs to the fabric. Discover how this efficient technique can enhance your creative projects and provide lasting results on cotton, polyester, and other textiles. Join us as we delve deeper into the exciting world of DTF transfers and learn how to elevate your custom printing game.

Direct-to-Film printing, often referred to simply as DTF printing, is a cutting-edge technique taking the apparel industry by storm. This method allows designers to print directly onto a special film that can be easily transferred onto fabric using a heat press. With a variety of applications and exceptional results, this custom garment printing approach is becoming increasingly popular among both professional and hobbyist creators. From preparing your artwork to understanding DTF printing materials, the knowledge required to master this technique opens new avenues for artistic expression. As we explore this topic further, you’ll gain insights into how DTF transfers can revolutionize your printing projects.

Exploring the Basics of DTF Transfers

Direct-to-Film (DTF) transfers are gaining popularity due to their ability to produce high-quality designs on various textiles. This method not only simplifies the printing process but also enables vibrant color applications that are durable and long-lasting. This guide aims to delve deeper into what DTF transfers entail, exploring their unique mechanisms and benefits over traditional printing methods such as Direct-to-Garment (DTG) printing.

One of the key advantages of DTF transfers is the versatility they offer to users. Unlike DTG printing, which often requires pre-treatment of fabric, DTF allows you to print on a wide array of fabric colors and types without these extra steps. This flexibility makes DTF transfers an ideal choice for custom textile printing projects, catering to both hobbyists and professionals looking to produce eye-catching designs efficiently.

Essential Tools for DTF Printing

To achieve successful DTF transfers, gathering the right materials is crucial. You will need a specific DTF printer that can handle the unique inks and films required for this process. Additionally, the quality of the transfer film plays a significant role in the final output, making it vital to select high-grade films designed explicitly for DTF applications.

Another essential component is the adhesive powder which binds the ink to the transfer film. This powder’s quality directly impacts the durability of the final design on fabric. To properly apply the printed design, a reliable heat press is also necessary to ensure the right amount of pressure and heat is applied during the transfer process, allowing for flawless results.

Step-by-Step Guide to DTF Printing

Embarking on your DTF printing journey requires following a well-structured process developed over time. Begin with selecting or creating a design suited to your project dimensions. Utilizing graphic design software allows you to save the design in high resolution, which is crucial for producing vibrant and detailed prints.

Once your design is prepared, the next step involves printing it onto the transfer film using your DTF printer. It’s imperative to set your printer settings according to the film specifications to ensure optimal ink application. After printing, the careful application of the adhesive powder while the ink is wet is vital, as it strengthens the bond between the ink and the film.

Best Practices for Quality DTF Transfers

To ensure the success of your DTF transfers, adherence to best practices is essential. One key step is fabric preparation; your fabric should be clean and devoid of any dust or oils, which could disrupt the adhesive’s effectiveness. Taking the time to properly prepare your materials can significantly improve the quality of the final product.

Another best practice is conducting test prints on sample fabric before proceeding with your main project. This approach allows you to fine-tune your settings and techniques, ultimately enhancing the graphical output without wasting materials. Regular maintenance of your printer is also recommended to avoid common issues that may arise over time.

Recent Trends in DTF Technology

As of 2024, the DTF printing landscape has seen remarkable advancements that are exciting for both novices and seasoned printers alike. New models of DTF printers are being introduced that promise enhanced printing speeds and improved cost efficiency. These innovations can significantly benefit both small businesses and hobbyists by reducing overhead costs and increasing production capabilities.

Additionally, modern DTF printers are being designed with eco-friendly ink formulations – thus lowering the heat requirements during the printing process, while maintaining exceptional print quality and vibrancy. Such advancements hint at a continually evolving landscape where high technology and sustainability intersect beautifully.

Staying Updated with DTF Trends

With the rapid growth of DTF technology, staying informed is critical for anyone invested in custom textile printing. Industry resources such as Printwear Magazine and T-Shirt Magazine offer a plethora of insights, ranging from current best practices to emerging trends. Regularly consulting these publications can provide invaluable information on how to leverage new DTF tools and techniques.

Moreover, engaging with online communities and forums can help you connect with fellow printer enthusiasts and professionals. Sharing experiences and advice within these networks can enhance your skills and enable you to stay ahead of the curve in this dynamic field.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, utilize a special printing process where designs are printed onto a transfer film and then applied to fabrics using a heat press. This method allows for vibrant and durable prints on a variety of fabrics, making it popular for custom textile printing.

What materials do I need for DTF printing?

To successfully execute DTF printing, you need a DTF printer, DTF transfer film, hot melt adhesive powder, and a heat press. Optional items include protective sheets for the heat press to enhance the transfer process.

How does heat press transfer work in DTF printing?

In DTF printing, the heat press transfer applies heat and pressure to the cured design on the transfer film, adhering it to the fabric. Optimal temperatures vary between 300°F to 330°F, typically requiring a 10 to 15 second press for best results.

Can I use DTF transfers on any type of fabric?

Yes, DTF transfers can be used on a variety of fabrics, including cotton, polyester, and fabric blends. This versatility is a key advantage of DTF printing over other methods, allowing customization on both light and dark textile colors.

What are some tips for successful DTF printing?

For successful DTF printing, ensure your fabric is clean and free of oils, perform test prints on scrap material, and maintain your DTF printer regularly. These practices enhance print quality and overall durability of the designs.

Where can I find tutorials for DTF printing?

For comprehensive guides, including step-by-step tutorials on DTF printing, you can refer to industry resources like Printwear Magazine and T-Shirt Magazine, which offer insights and support for both beginners and experienced printers.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | DTF transfers utilize a special film to print designs transferred to various textiles with heat and pressure. |

| Advantages of DTF Transfers | DTF allows vibrant, durable prints on different fabric colors without pre-treatment, making it versatile and efficient. |

| Materials Needed | DTF printer, transfer film, adhesive powder, heat press, and optional protective sheets. |

| Process Steps | 1. Prepare the design 2. Print the design 3. Apply adhesive powder 4. Cure the adhesive 5. Transfer to fabric 6. Peel off the film |

| Best Practices | Ensure fabric cleanliness, perform test prints, and maintain printer regularly for optimal results. |

| Recent Developments | New DTF printers offer faster speeds, eco-friendly inks, and auto-cleaning features, enhancing print quality. |

Summary

DTF Transfers revolutionize the garment printing landscape by offering an efficient method to achieve vibrant and durable designs on various textile types. This tutorial breaks down the entire process, ensuring that even beginners can embark on their creative projects with confidence. By utilizing the right materials and following the outlined steps, anyone can produce professional-quality prints tailored to their unique style. As advancements in DTF technology continue to emerge, there’s never been a better time to explore the endless possibilities of DTF Transfers.