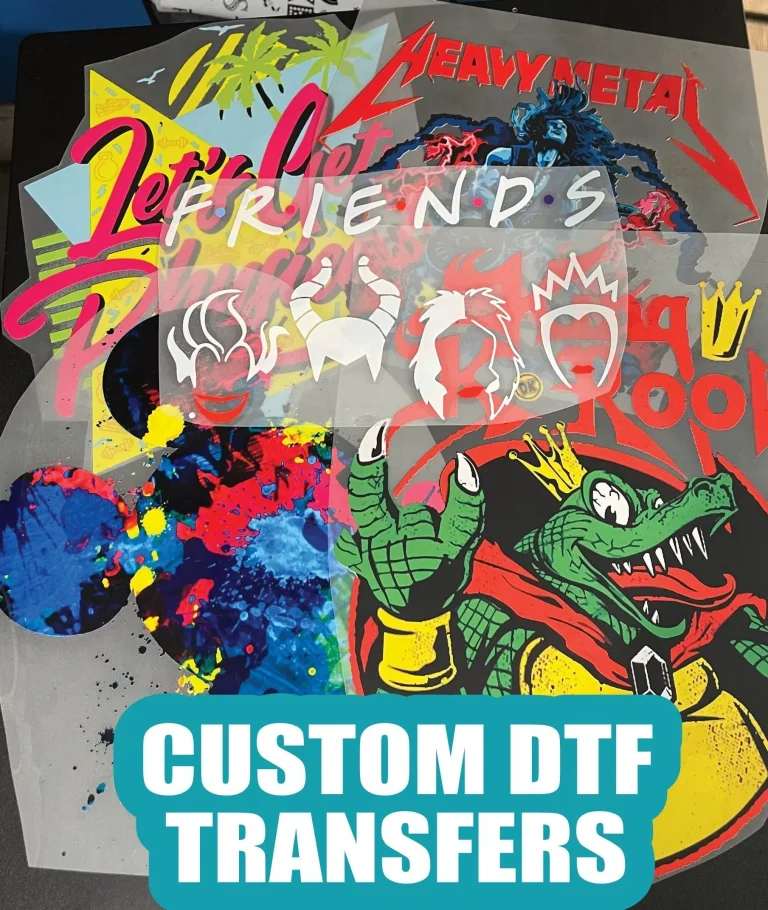

DTF Printing Process: From Concept to Creation Explained

The DTF printing process, or Direct-to-Film printing, has emerged as a groundbreaking advancement in the realm of custom apparel printing, allowing designers to unleash their creativity on a wide range of fabrics. This innovative method utilizes a unique technique that involves printing vibrant designs onto special transfer films, which are then heat pressed onto textiles, ensuring exceptional quality and durability. One of the most appealing DTF printing advantages is its versatility, accommodating multiple fabric types from cotton to polyester, thus broadening its applications across various industries. As a sustainable printing method, DTF printing incorporates eco-friendly water-based inks, aligning with the growing demand for environmentally conscious production practices. This blog post will explore the intricate details of the DTF printing process, spotlighting its essential role in modern textile printing.

Direct-to-Film (DTF) printing represents a revolutionary technique in the textile and custom apparel landscape, redefining how designs are transferred to fabric. This sophisticated method integrates the concepts of film-based printing with heat transfer technology, resulting in stunning designs that adhere seamlessly to different textile types. Known for its adaptability and vibrant color reproduction, DTF printing serves a multitude of applications including fashion apparel and marketing merchandise. The process employs eco-friendly inks and efficient production practices, making it one of the forefront sustainable printing methods available today. In this discussion, we will uncover the nuances and workings of the DTF printing process, highlighting why it has become a favored choice among businesses aiming for quality and efficiency.

The Fundamentals of DTF Printing Process

Understanding the fundamentals of the Direct-to-Film (DTF) printing process is essential for anyone looking to harness its capabilities for custom apparel printing. DTF printing starts with a unique film, onto which your desired designs are printed using specialized DTF inks. This process is not just about creating vibrant images; it’s about understanding how to manipulate heat transfer and adhesive application for effective design. The film acts as a medium, ensuring that every detail of the design is captured and transferred flawlessly to fabric, whether it’s cotton or polyester.

The method consists of three main steps: printing, adhesive application, and heat transfer. In the printing phase, the high-quality DTF inks are used to achieve a rich color spectrum and fine detail. Following this, an adhesive powder is applied that bonds with the printed ink when heat is introduced. Finally, through a heat press, this setup transfers the creativity onto garments, ensuring durability and a professional finish. Each step is crucial in determining the final output and making DTF printing a preferred choice for many.

Advantages of DTF Printing Technology

DTF printing comes with a myriad of advantages that appeal to business owners and designers alike. One of the standout features of DTF printing technology is its high versatility. It can be employed on a wide range of fabric types, from lightweight synthetic materials to thicker, organic garments. This flexibility means that you can expand your product offering without needing separate print techniques for different fabrics. Additionally, the ability to produce stunning, vibrant colors and detailed graphics makes DTF printing a top contender in the custom apparel printing market.

Beyond versatility, DTF printing is remarkably cost-effective, particularly for small businesses and startups venturing into custom apparel. The overall cost is significantly lower for small batch runs compared to traditional methods such as screen printing, which often requires extensive setup and larger minimum orders. This economical approach provides an opportunity for entrepreneurs to explore their creative designs without the burden of hefty upfront investments, democratizing fashion and personalized product offerings in the process.

Exploring DTF Printing Applications Across Industries

The applications of DTF printing are robust and span a variety of industries. The fashion industry has particularly embraced this technology, allowing designers to create unique garments and innovative accessories that captivate the market. DTF printing enables the production of intricate patterns and vivid illustrations, making it possible to push the boundaries of traditional fashion design.

Sporting goods manufacturers are also reaping the rewards of DTF technology. Custom team jerseys and sports gear benefit from the high durability and color vibrancy that DTF printing offers, enabling fans and athletes alike to showcase their team spirit with personalized flair. Moreover, DTF printing is a popular choice for promotional items; businesses utilize this technology to create engaging and vibrant marketing materials that make a lasting impression while branding their identity.

Sustainability Considerations in DTF Printing

As the global community grows increasingly concerned about environmental sustainability, the DTF printing process is aligning itself with these values through the use of eco-friendly materials and techniques. DTF printing employs water-based inks that significantly reduce the environmental footprint when compared to traditional inks. This innovation not only meets the high demands of consumers but also assures businesses that they are contributing to greener production practices.

In addition to using eco-conscious inks, the efficient production methods characteristic of DTF printing minimize waste significantly. This sustainable angle is becoming a crucial selling point for brands as consumers prefer to support businesses that prioritize environmentally friendly practices. By adopting DTF printing, companies can proudly advertise their commitment to sustainable printing methods, appealing to a market that increasingly values corporate responsibility.

Market Growth and Trends in DTF Printing

The DTF printing market is witnessing remarkable growth as businesses across sectors recognize the technology’s potential. A report by Research and Markets hints at a rising demand for personalized apparel driven by e-commerce’s expansion. This shift is empowering businesses to leverage DTF printing for products tailored closely to consumer preferences, reinforcing the push towards mass customization while minimizing production lag times.

Recent trends indicate that as technology evolves, so too do the capabilities of DTF printing. Innovations in printer tech and ink formulations contribute to enhanced durability, color fidelity, and production speeds. Businesses that capitalize on these advancements can meet the burgeoning demand for innovative designs more effectively, placing DTF firmly at the forefront of textile printing solutions.

Why Choose DTF Printing for Custom Apparel?

Choosing DTF printing as your custom apparel printing solution presents a multitude of benefits, making it an attractive option for various businesses. The process, which includes efficient printer capabilities and eco-friendly materials, suits both newcomers and seasoned professionals in the fashion and merchandise sectors. DTF printing offers the ability to produce intricate designs on various fabric types without compromising quality, appealing to a diverse clientele.

Additionally, one of the most mystical aspects of choosing DTF is its adaptability to small production runs, allowing businesses to maintain a competitive edge. The ability to print on demand, without significant inventory investments, aligns perfectly with today’s fast-paced market, where consumer preferences can shift swiftly. By integrating DTF printing into their production line, brands can respond promptly to trends and customer requests, thus enhancing overall customer satisfaction and loyalty.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct-to-Film printing, involves printing designs onto a special film which is then heat transferred onto fabrics. This method includes three main steps: printing the design with water-based DTF inks, applying a hot-melt adhesive powder to the printed film, and finally using heat to transfer the design onto the fabric.

What are the key DTF printing advantages for custom apparel?

DTF printing offers several advantages for custom apparel, including high versatility across various fabric types, cost-effectiveness for small production runs compared to traditional methods, and ease of use, making it accessible for those new to textile printing.

In what applications can DTF printing be used?

DTF printing applications include fashion, sportswear, promotional products, and custom apparel. It is ideal for creating vibrant and durable designs on a variety of materials, including cotton and polyester blends.

How sustainable is the DTF printing process compared to other printing methods?

The DTF printing process supports sustainability through the use of water-based inks, which are environmentally friendly, and efficient production methods that minimize waste, making it a more responsible choice compared to many traditional printing methods.

What recent developments are occurring in DTF printing technology?

Recent developments in DTF printing technology focus on improving ink formulations for better quality and durability, as well as advancements in printer capabilities that allow for faster production speeds and reduced costs, responding to the growing market demand.

Can small businesses benefit from DTF printing?

Yes, small businesses can greatly benefit from DTF printing due to its cost-effectiveness for smaller runs, allowing them to enter the custom apparel market without significant investment. The ease of learning the process also enables quick production of quality items.

| Key Aspect | Description |

|---|---|

| What is DTF Printing? | A modern printing technique transferring designs from film to fabric using heat. |

| Main Steps in DTF Printing | 1. Printing the design on DTF transfer film. 2. Applying hot-melt adhesive powder to the printed film. 3. Transferring the design onto fabric with heat. |

| Advantages | – High versatility across various fabrics. – Cost-effective for small production runs. – An easier learning curve for beginners. |

| Recent Developments | Market growth due to personalized apparel demand and technological advancements in ink and equipment. |

| Application Industries | Fashion, sportswear, and promotional products adopting DTF for custom designs. |

| Sustainability Efforts | Incorporating eco-friendly inks and materials to meet environmental consciousness. |

Summary

The DTF printing process represents a transformative shift in the textile printing landscape, making it a popular choice for businesses aiming for efficient and cost-effective solutions. This innovative method not only allows for stunning custom designs but also caters to a diverse range of fabrics, ensuring versatility and quality in production. As the technology evolves, we can expect continuous improvements in speed and sustainability, solidifying DTF printing’s role in various industries, from fashion to promotional products.