DTF Transfers: Unlocking the Magic with Tips and Insights

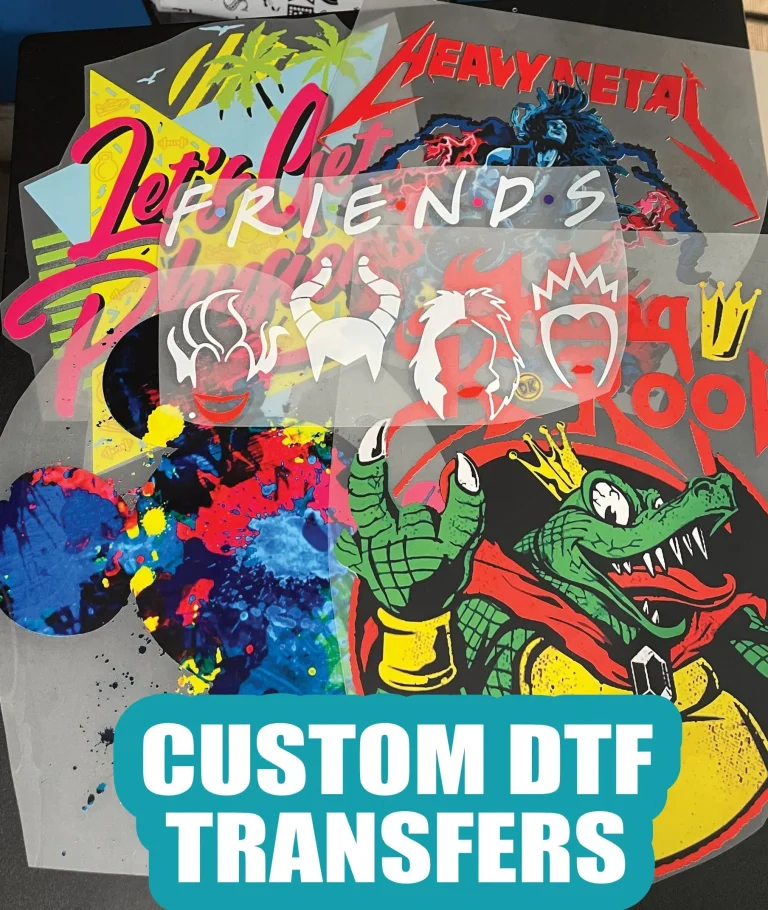

DTF Transfers, short for Direct-to-Film transfers, represent a groundbreaking advancement in the print industry, uniquely combining quality, versatility, and durability. This innovative printing technique enables creators and businesses alike to achieve high-quality fabric prints with vibrant colors and intricate designs. By utilizing ecological DTF inks, printers can not only enhance their output but also contribute to a sustainable approach in manufacturing. Whether you’re embarking on a custom apparel project or exploring promotional items, understanding the benefits of DTF transfers can spark fresh creative ideas. Join us as we delve into the pros, cons, and essential tips for maximizing the effectiveness of DTF printing in your endeavors.

The world of DTF transfer printing, often referred to as Direct-to-Film printing, has revolutionized the way designers and manufacturers approach the creation of custom graphics. This method leverages a specialized film that allows detailed designs to be heat-transferred onto a variety of fabric materials, significantly expanding its applicability. With numerous DTF printing benefits, including its ability to produce high-quality fabric prints while ensuring durability and vibrancy, it’s no wonder that this technique is gaining traction within the crafting and business communities. Additionally, adopting ecological DTF inks can further enhance the appeal of this printing method, aligning it with modern sustainability efforts. Explore with us the essential tips for successful DTF transfers and discover how to make the most of this innovative printing technology.

Understanding the DTF Printing Process

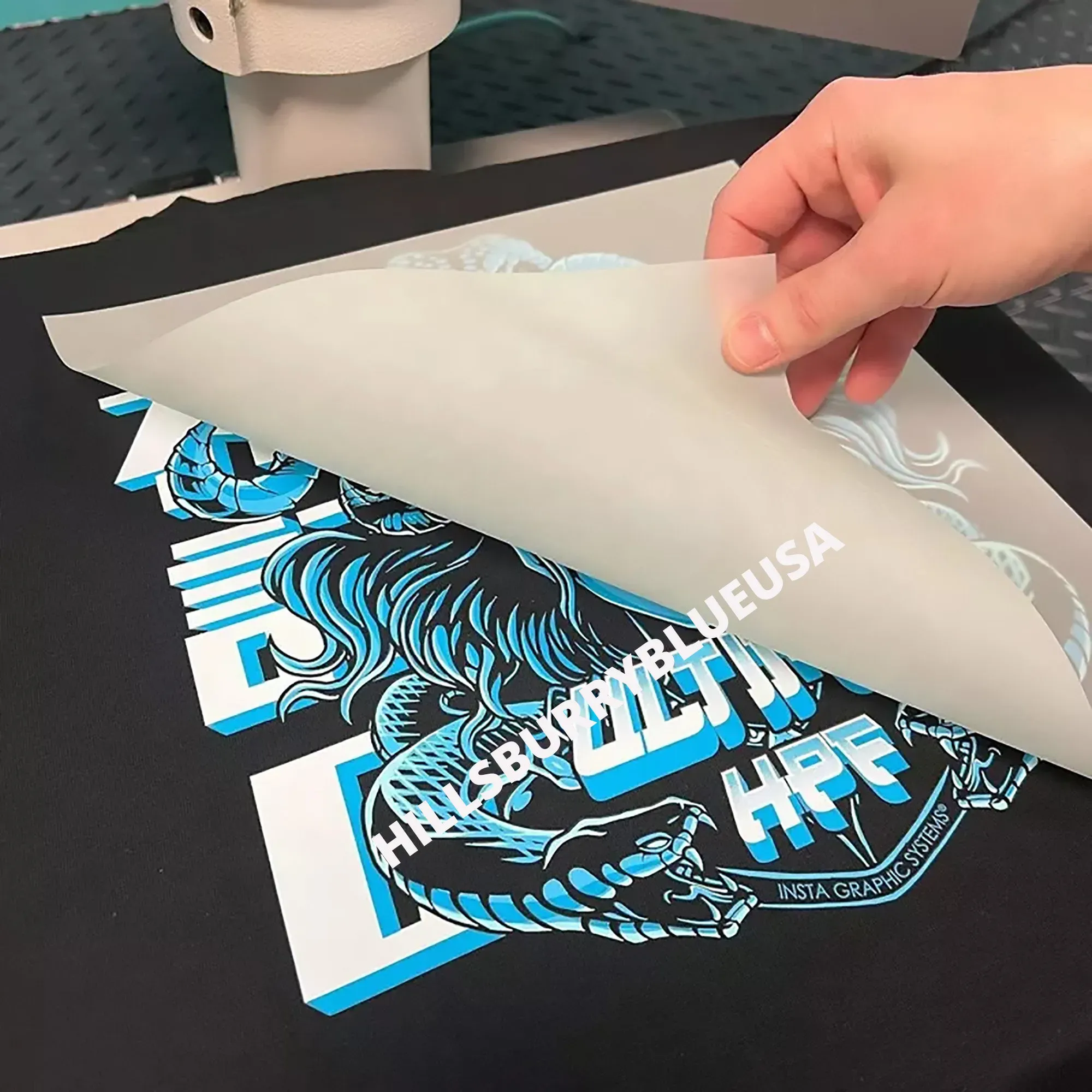

The Direct-to-Film (DTF) printing process involves several key steps that ensure high-quality fabric prints. Initially, designs are printed on a special film using DTF inks, which are known for their superior color vibrancy and detail retention. This process amplifies the capabilities of traditional screen printing by allowing for intricate graphics and smooth gradients. Once the print is completed, the film is coated with a hot-melt adhesive, which secures the artwork in preparation for the transfer phase.

After the adhesive application, the film is heat-pressed onto the desired fabric. This crucial step in the DTF process requires careful control over temperature and pressure settings to ensure that the design adheres effectively to the fabric. The beauty of DTF printing lies in its versatility, allowing it to be applied to various materials such as cotton, polyester, or blends, making it ideal for everything from custom t-shirts to home décor.

Benefits of DTF Printing for Businesses

DTF printing provides numerous benefits that cater specifically to the needs of businesses looking to create custom apparel and merchandise. One of the standout advantages is the ability to produce high-quality prints that remain vibrant even after multiple washes, thanks to the durability of DTF inks. This quality not only meets customer expectations but also enhances the overall brand image, making products more appealing.

Furthermore, the versatility of DTF transfers means that businesses can expand their product offerings without the need for multiple printing setups. Whether producing simple logos or complex designs, DTF printing accommodates various fabric types, allowing entrepreneurs to target diverse markets and customer preferences. This adaptability helps businesses remain competitive in a rapidly evolving industry.

Key DTF Transfer Tips for Optimal Results

To achieve the best possible results in DTF printing, specific tips can significantly enhance quality and efficiency. Firstly, selecting high-quality DTF films and inks is essential; inferior materials can lead to poor adhesion and color fidelity. Investing in premium products ensures that the prints not only look great upon application but also withstand the test of time.

Additionally, performing test prints on sample fabrics can help identify optimal heat settings and pressure variations before commencing a full production run. This practice minimizes waste and ensures that the finished product aligns with client expectations. Mastering these details is crucial for both established businesses and newcomers in the DTF landscape.

The Durability of DTF Transfers

A significant characteristic that sets DTF transfers apart from other printing methods is their remarkable durability. Unlike screen-printed designs that may fade or crack over time, DTF prints are designed to withstand intensive use, making them suitable for daily wear items such as clothing and accessories. This longevity not only increases customer satisfaction but also supports repeat business for companies.

The durability of DTF transfers is attributed to the strong bonding formed between the adhesive applied on the film and the fabric during the heat transfer process. As a result, prints maintain their vibrancy and detail for years, reinforcing the value proposition for businesses aiming to provide lasting products. This feature is especially appealing for promotional items that are meant to leave a lasting impression on consumers.

Ecological Considerations in DTF Printing

With the rising importance of sustainability in the printing industry, ecological DTF inks are making waves by minimizing the impact on the environment. Recent advancements have led to the development of water-based inks that not only deliver the same vibrant results as traditional inks but also reduce harmful emissions. By embracing these eco-friendly alternatives, businesses can appeal to conscientious consumers while contributing to environmental preservation.

Incorporating ecological practices into DTF printing also enhances brand reputation. Companies that prioritize sustainability often attract customers who value green initiatives, thereby expanding their reach in the market. As the landscape of printing evolves, adapting to these ecological advancements positions businesses as leaders in responsible manufacturing.

Common Challenges in DTF Transfers and Solutions

While DTF transfers offer many advantages, there are common challenges that practitioners may face. For instance, achieving consistent print quality can be tricky due to variables such as temperature fluctuations and film type. Beginners often encounter issues such as ink adhesion or improper heat settings, which can compromise the final product. Identifying these pain points early on is crucial to developing effective solutions.

Regular maintenance of printing equipment is vital to overcoming these challenges. Keeping printers and heat presses clean and well-calibrated minimizes the potential for errors and ensures that the machinery operates at peak efficiency. Additionally, engaging in community forums can provide valuable insights and troubleshooting tips that help navigate common obstacles in the DTF printing process.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film that can then be heat-pressed onto various fabrics. This printing technique combines elements of traditional screen printing with modern digital printing to produce high-quality fabric prints with vibrant colors and fine details.

What are the benefits of using DTF printing for fabric designs?

The benefits of DTF printing include high-quality fabric prints that maintain vibrancy over time, versatility to print on diverse materials like cotton and polyester, and excellent durability that withstands washing without damage. Additionally, DTF transfers offer intricate detail capabilities that are ideal for complex designs.

What tips can help achieve success with DTF transfers?

To achieve success with DTF transfers, consider these tips: use high-quality inks and films, conduct test prints before a full run, fine-tune your printer settings for best results, and master heat press techniques for proper adhesion without fabric damage.

Are there any ecological benefits of using DTF inks?

Yes, ecological DTF inks are designed to be less harmful to the environment. Recent advancements in the DTF printing industry have led to the development of innovative, water-based inks that align with growing sustainability efforts in printing, making DTF an eco-friendlier choice.

What challenges might beginners face when using DTF transfers?

Beginners might face challenges such as a steep learning curve regarding the printer settings, ink adhesion, and film manipulation. Additionally, the initial investment in specialized DTF printing equipment and materials can be significant, which may pose a hurdle for those just starting out.

How do DTF transfers compare to other printing methods like DTG or screen printing?

DTF transfers differ from Direct-to-Garment (DTG) and screen printing in that they offer high-quality fabric prints that are versatile for various material types and provide durability over time. While DTG is more suited for cotton fabrics, DTF can print on a broader range, making it a more flexible solution for many businesses.

| Key Aspect | Details/Description |

|---|---|

| Definition | DTF transfers involve printing designs onto film for heat transfer to various fabrics. |

| Pros | High-quality prints with vibrant colors and intricate details. |

| Versatility | Applicable to multiple fabric types including cotton and polyester. |

| Durability | Resistant to fading and cracking, ideal for long-lasting products. |

| Cons | Initial investment for equipment can be substantial. |

| Learning curve | Navigating the DTF process may require practice and experimentation. |

| Equipment maintenance | Regular upkeep is needed to maintain print quality. |

| Tips | Use quality materials and conduct test prints to achieve best results. |

| Recent Developments | Emergence of eco-friendly, water-based inks for sustainability. |

Summary

DTF Transfers are revolutionizing the printing industry, unlocking a world of creative potential for both businesses and hobbyists. This innovative method offers exceptional quality, versatility across various fabric types, and impressive durability, making it a preferred option for custom designs. While there are considerations such as initial investment and learning curves, the benefits significantly outweigh the challenges. By implementing effective techniques and staying informed about advancements, you can maximize success with DTF Transfers, creating long-lasting, vibrant prints that cater to diverse needs.