DTF Transfers: The Future of Custom Printing Explained

In the evolving landscape of custom printing, DTF transfers are revolutionizing the way designs are applied to fabric. Short for Direct-to-Film printing, this innovative technology allows for vibrant, high-quality images that adhere seamlessly to diverse materials. As businesses and consumers increasingly demand sustainable and efficient methods, DTF technology stands out by minimizing waste and offering eco-friendly printing solutions. This post delves into why DTF transfers are not just a fleeting trend but are destined to become a cornerstone of the fabric printing industry. Join us as we explore the myriad benefits and advancements driving the future of custom printing.

Also known as Direct-to-Film printing, DTF transfers represent a significant advancement in the world of custom designs. This technique enables a flawless application of intricate patterns on various types of material, making it ideal for businesses and creative enthusiasts alike. Beyond mere aesthetic appeal, it harnesses cutting-edge technology to create eco-friendly printing processes that meet the growing demand for sustainability. The versatility of DTF not only caters to individual customization but also adapts efficiently to larger production needs. In this evolving market, understanding the nuances of DTF and its alternatives is vital for anyone looking to thrive in the future of fabric printing.

Exploring the Advantages of DTF Transfers

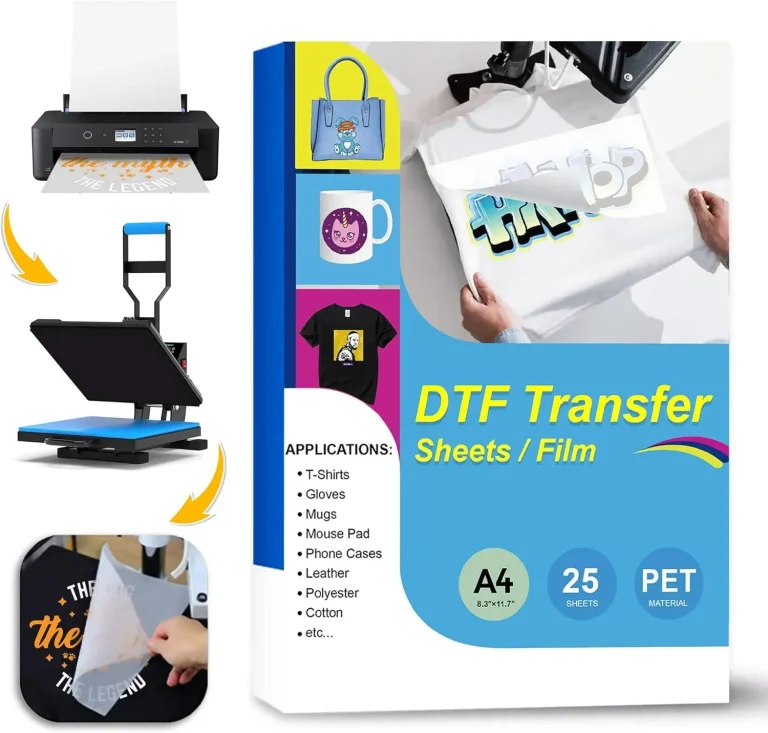

Direct-to-Film (DTF) transfers offer numerous advantages that set them apart from traditional fabric printing methods. The process begins with printing designs onto a specialized film, which is then transferred onto various fabric materials. This method allows for incredible detail and vibrant colors while offering durability and resistance to fading. Businesses utilizing DTF technology can achieve stunning visual results that enhance the appeal of their products, making DTF transfers an indispensable tool for brands focused on quality and aesthetics.

Moreover, DTF technology caters to various industries, providing businesses the flexibility to produce small or large batches without compromising quality or incurring high costs. Unlike screen printing, which often has high initial setup costs, DTF’s streamlined approach allows both start-ups and established companies to offer custom prints. The combination of affordability and versatility ensures that DTF continues to gain traction among fabric printing businesses, marking its place as a staple in the custom printing industry.

Cost Efficiency in DTF Printing

One of the standout features of DTF transfers is their cost efficiency, particularly appealing to small and medium-sized enterprises. With traditional methods requiring significant investment upfront—such as screens, inks, and setup processes—DTF eliminates many of these barriers. Businesses can produce high-quality prints on demand without the need for extensive inventory, which in turn reduces waste and storage costs. This print-on-demand model allows companies to stretch their budgets further and react swiftly to changing market demands.

Furthermore, the adaptability of DTF technology means fewer resources are wasted during production. Customization becomes a straightforward process, where businesses can easily cater to individual customer preferences without incurring large expenses. This efficiency not only bolsters a company’s bottom line but enhances their overall responsiveness to customer requests, further strengthening their market position.

The Eco-Friendly Edge of DTF Transfers

In today’s environmentally-conscious market, consumers are increasingly making choices based on sustainability. DTF transfers address these concerns through eco-friendly practices that minimize waste and reduce environmental impact. Unlike conventional fabric printing, which often relies on harmful chemicals and excessive water usage, DTF printing utilizes water-based inks and eco-solvent options. This innovative approach significantly lowers the ecological footprint associated with the printing process, catering to consumer demand for sustainable products.

Additionally, the efficiency of DTF technology leads to less material waste. Traditional methods often suffer from overproduction and excess inventory, while DTF’s print-on-demand capabilities ensure that only what is needed is produced. This not only conserves valuable resources but also aligns with sustainable business practices that resonate with today’s eco-conscious shoppers.

Technological Innovations Driving DTF Forward

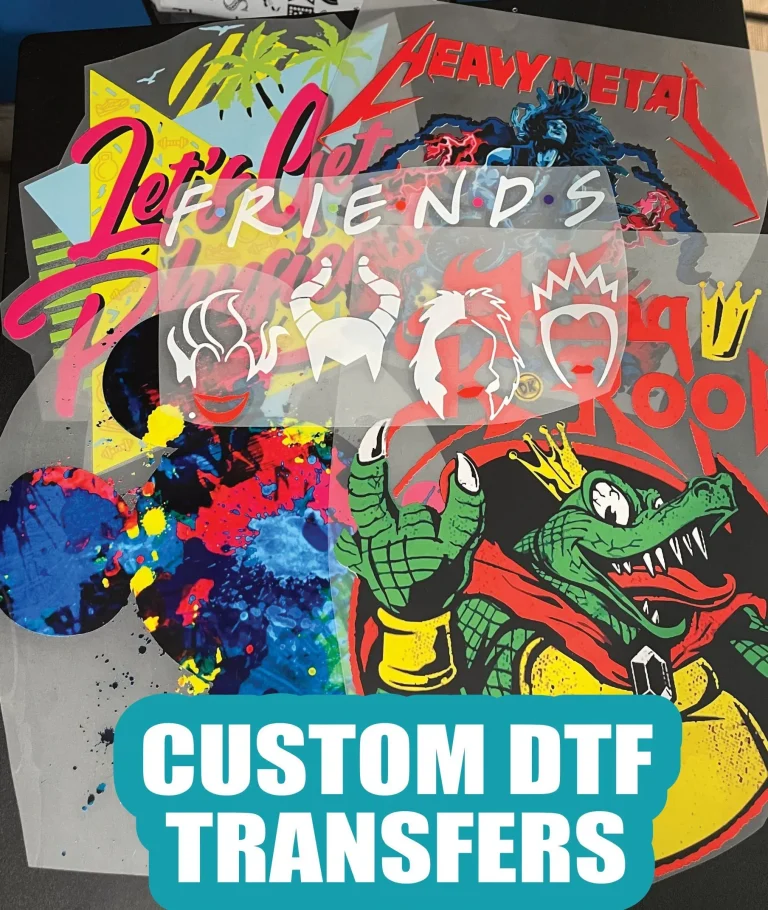

The ongoing evolution of DTF technology is fundamental to its growing popularity and effectiveness in custom printing. With advancements in ink formulations and transfer films, the quality of prints produced through DTF methods continues to improve. The introduction of high-resolution printers has allowed businesses to create intricate designs with exceptional detail, capturing consumer attention in an increasingly competitive market.

These technological innovations are crucial for meeting consumer expectations. Today’s buyers seek unique and personalized experiences, and DTF provides the versatility to deliver just that. As technology continues to advance, businesses that embrace DTF are better positioned to meet the diverse needs of their clientele, ensuring they remain at the forefront of the custom printing industry.

Market Trends Indicating the Future of DTF Printing

Market forecasts suggest that DTF printing is set for significant growth in the coming years. As more businesses recognize the advantages of this technology, from faster production times to detailed and colorful designs, the demand for DTF transfer capabilities is likely to soar. The ability to quickly adapt to trends and consumer preferences gives businesses utilizing DTF technology a competitive edge, positioning them to succeed in a rapidly evolving market.

This projected growth is supported by the increasing consumer appetite for customization and personalization in products. Whether in apparel, accessories, or promotional items, the versatility of DTF transfers allows companies to cater to individual tastes, making them invaluable in the contemporary consumer landscape. As the industry moves forward, DTF is set to become a cornerstone of fabric printing.

Understanding the Comprehensive Benefits of DTF Transfers

The full range of benefits offered by DTF transfers cannot be understated. Beyond high-quality prints and cost savings, DTF technology also enables businesses to diversify their offerings. Brands can produce everything from unique, one-off designs for individual clients to larger commercial runs, all while maintaining the same level of quality and consistency. This flexibility is a major advantage in a market that values individual expression.

Additionally, the sustainability factor is becoming increasingly relevant in consumer purchasing decisions. Companies leveraging DTF processes can effectively communicate their commitment to eco-friendly practices while delivering high-quality products. This dual benefit not only attracts eco-conscious consumers but also positions businesses as responsible players in the industry, aligning with the growing trend towards responsible manufacturing.

Frequently Asked Questions

What are DTF transfers and how do they differ from traditional fabric printing?

DTF transfers, or Direct-to-Film transfers, are a revolutionary printing method used in custom fabric printing. Unlike traditional methods that may require screens or complex setups, DTF technology prints designs directly onto a special film, which is then heat-pressed onto various fabrics. This allows for more vibrant colors and intricate designs on materials like cotton and polyester without compromising durability.

Why should businesses consider using DTF transfers for their custom printing needs?

Businesses should consider DTF transfers for their custom printing needs due to their cost-effectiveness and versatility. DTF technology allows for small batch printing without high setup costs, making it ideal for print-on-demand services. Additionally, DTF transfers produce high-quality prints that withstand many washes, increasing the longevity of printed items, which is crucial for customer satisfaction.

Are DTF transfers an eco-friendly option for fabric printing?

Yes, DTF transfers are considered an eco-friendly printing option. This method uses less water and energy compared to traditional fabric printing techniques, and many DTF printers now utilize eco-solvent inks. By minimizing material waste and promoting sustainable practices, DTF technology aligns with the growing demand for eco-friendly printing solutions among consumers.

What materials can be used with DTF transfers in custom printing?

DTF transfers are highly versatile and can be applied to a wide range of materials, including cotton, polyester, and various fabric blends. This flexibility makes them suitable for diverse applications in custom printing, allowing businesses to cater to different customer preferences and product requirements seamlessly.

How do technological advancements impact DTF printing?

Technological advancements significantly enhance DTF printing by improving transfer films, inks, and printer capabilities. These innovations lead to superior print quality, enabling high-resolution images with intricate details to be produced quickly. As the industry evolves, businesses adopting DTF technology can stay competitive and meet the increasing demand for customized solutions efficiently.

What is the expected future of DTF transfers in the custom printing industry?

The future of DTF transfers in the custom printing industry looks promising, with market analysts predicting significant growth in adoption rates. As more businesses recognize the advantages of DTF, including rapid production times and the ability to print detailed designs on various fabrics, DTF transfers are set to become a staple in custom fabric printing, shaping the industry’s landscape.

| Key Points | Details |

|---|---|

| Growth in Popularity and Versatility | DTF transfers can print on various fabric types while maintaining color integrity, making them ideal for manufacturers and custom printers. |

| Cost-Effectiveness | Lower setup costs and efficient for small batches, allowing customization at a reduced price for businesses. |

| Environmental Considerations | DTF is more eco-friendly, using less water and energy and utilizing eco-solvent inks. |

| Technological Advancements | Continuous innovation in transfer films and printers is improving print quality and efficiency. |

| Market Projections | Significant rise in adoption expected as businesses realize DTF benefits. |

| Benefits of DTF in Custom Printing | High-quality, flexible, sustainable, and faster production capabilities. |

Summary

DTF transfers are revolutionizing the custom printing landscape through their flexibility, cost-efficiency, and eco-consciousness. As the demand for high-quality fabric printing escalates, DTF transfers stand out as an ideal choice for businesses aiming to meet consumer expectations. Their ability to produce vibrant prints on various fabrics without compromising durability or environmental standards positions DTF as a leading technology in the custom printing market. With ongoing advancements and a promising growth trajectory, DTF transfers are indeed here to stay and are set to play a pivotal role in the future of the printing industry.