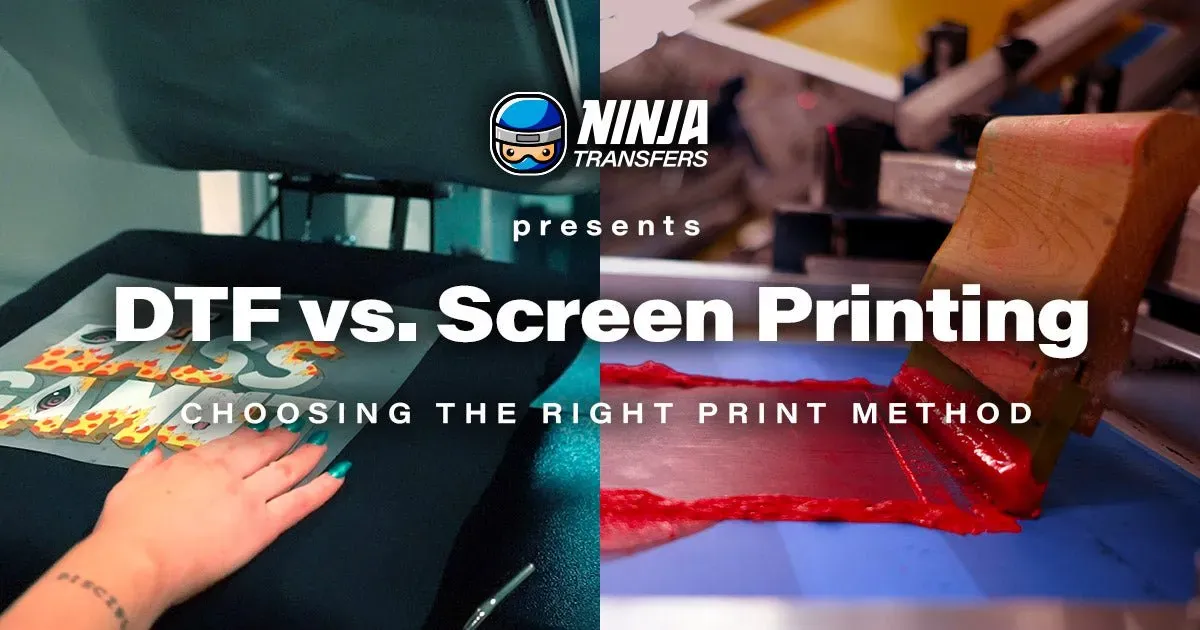

DTF Transfers vs. Screen Printing: Which is Better?

When it comes to garment decoration methods, the debate between DTF transfers vs. screen printing is ever-present in the custom apparel printing landscape. Each technique boasts its own set of features, advantages, and challenges that can greatly influence your choice for promotional needs. DTF printing benefits include the capability of producing detailed designs with vibrant color outputs, while screen printing advantages lie in its cost-effectiveness for bulk orders. Whether you’re considering print quality comparison or evaluating durability, understanding the distinctions between these methods is essential. This guide will help you navigate through the complexities to make an informed decision that aligns with your business goals.

In the world of custom garment printing, several techniques vie for attention, notably the Direct-to-Film (DTF) transfer process and traditional screen printing. These methodologies present unique characteristics that cater to different printing needs, from intricate designs to large scale production. Understanding the differences in technical execution, material compatibility, and overall cost-effectiveness can greatly aid in selecting the right approach for your apparel needs. This article will explore these prominent printing methods, their benefits, and drawbacks, providing a comprehensive overview for businesses striving for quality and efficiency.

Key Benefits of DTF Printing

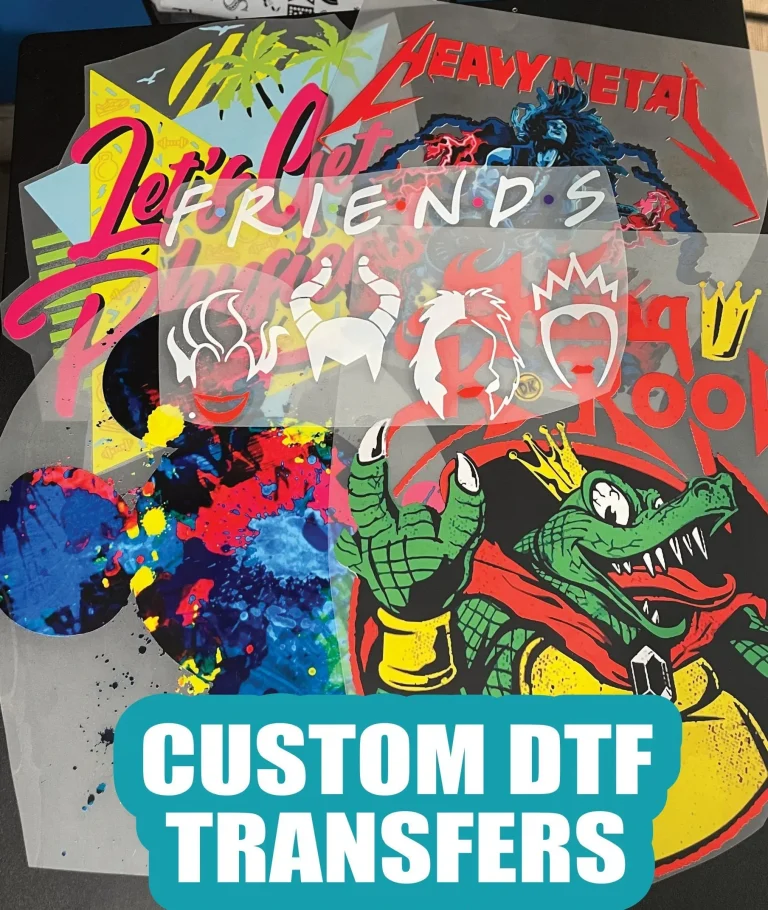

One of the standout advantages of DTF printing is its exceptional print quality. With the ability to handle intricate designs and a wide spectrum of colors, DTF is ideal for businesses that require high-resolution graphics. This method produces vivid prints that adhere well to various fabric types, making it especially popular for custom apparel. Furthermore, DTF technology has improved remarkably, ensuring better ink adhesion and long-lasting durability, similar to that of traditional methods. As businesses strive to stand out in a highly competitive market, the print quality of DTF transfers becomes a significant asset.

Another benefit of DTF printing is its cost-effectiveness for small runs. Businesses that focus on custom designs or individual orders often find that DTF offers lower production costs compared to screen printing. This is because DTF does not require screens or extensive setup, allowing for greater flexibility and reduced initial investment. As a result, small businesses can capitalize on the growing trend of tailored apparel without breaking the bank, enabling them to cater to niche markets effectively.

Advantages of Screen Printing

Screen printing has long been regarded as a cornerstone of the garment decoration industry, and for good reason. One of its primary advantages is the durability of prints. When properly cured, screen printed inks can withstand multiple washes and maintain their vibrancy over time, making it a preferred choice for bulk production. This durability not only satisfies customers looking for quality but also reduces reprints and waste, ultimately benefiting the bottom line for businesses.

In terms of economies of scale, screen printing excels for large orders. The initial setup costs and time may be higher, but once the screens are created, businesses can produce garments rapidly. For companies that regularly handle extensive printing jobs, screen printing can offer substantial long-term savings. This makes it a go-to method for promotional merchandise and uniform production, where consistency and volume are essential.

DTF Transfers vs. Screen Printing

When comparing DTF transfers to screen printing, it’s essential to evaluate the unique characteristics of each method. DTF printing allows for a quicker turnaround time thanks to its straightforward setup process. This method is particularly advantageous for small businesses that require rapid production without the overhead costs associated with screen printing. While both methods produce high-quality prints, DTF’s ability to efficiently produce detailed designs makes it a compelling option for niche markets and custom apparel.

However, screen printing holds its ground in terms of cost-efficiency for larger orders. Businesses planning extensive runs will benefit from the reduced cost per item associated with screen printing. Despite the longer setup time, once established, screen printing facilitates rapid output. Therefore, the choice between DTF transfers and screen printing largely hinges on production scale, design complexity, and specific business needs.

Cost Analysis of Custom Printing Methods

Cost is a critical factor in deciding between DTF transfers and screen printing. For small businesses or custom orders with diverse designs, DTF is often the preferred choice due to its minimal upfront costs. Without the requirement for screens, which can be costly and time-consuming to create, DTF enables more economically viable production of small batches. This accessibility allows entrepreneurs to provide tailored products without incurring prohibitive expenses.

In contrast, while screen printing can be more cost-efficient for large orders, the initial setup costs can be a barrier for smaller projects. This approach often necessitates bulk orders to truly reap the financial benefits. Therefore, businesses need to analyze their specific needs and project types to determine which printing method meets their financial model best.

Material Options for Various Printing Techniques

Material compatibility is another significant consideration when selecting a printing method. Screen printing is particularly effective on cotton fabrics but can limit choices when it comes to synthetic blends. This restriction can hinder creative possibilities, especially for designs intended for a wider range of apparel materials. As a result, brands may need to choose their designs based on material compatibility, which can restrict innovation.

On the other hand, DTF transfers boast impressive versatility, allowing prints on an array of fabrics, including cotton, polyester, and blends. This flexibility not only widens the scope of potential designs but also enables businesses to diversify their product offerings. As consumers increasingly demand unique and varied styles, the capability of DTF to adhere to multiple fabric types ensures that companies can meet these expectations.

Future Trends in Garment Decoration

Looking ahead, the future of garment decoration appears promising, especially for DTF printing. With advancements in technology continually enhancing ink quality and adhesion, the adoption of DTF methods in various industries is likely to increase. As businesses become more aware of the advantages that DTF brings, particularly for custom and on-demand printing solutions, they may gradually shift away from traditional methods.

Moreover, environmental considerations are driving the development of more sustainable printing options. Companies are tending to prioritize eco-friendly practices, which may favor DTF technology as it is often associated with reduced chemical usage compared to screen printing. As awareness and demand for sustainable products grow, the industry may see a larger pivot towards DTF as a cleaner alternative for garment decoration.

Frequently Asked Questions

What are the primary DTF printing benefits compared to screen printing?

DTF printing benefits include high-resolution prints, better color vibrancy, and the ability to print on a wider range of materials, making it ideal for custom apparel printing. Unlike screen printing, DTF transfers require less setup and offer a quicker turnaround for small orders.

How do the print quality comparisons between DTF transfers and screen printing affect design choices?

When evaluating print quality comparisons, DTF transfers often excel in intricate designs with multiple colors, delivering sharp details. In contrast, screen printing offers durability for bold designs but may struggle with detailed or multicolored graphics unless extensive setup is used.

What are the screen printing advantages for large production runs?

Screen printing advantages include lower per-unit costs for large quantities and faster production times once the screens are set up. It is especially efficient for bulk orders, making it a preferred method for businesses focusing on high-volume garment decoration.

Are there significant differences in cost-effectiveness between DTF transfers versus screen printing?

Yes, DTF transfers are generally more cost-effective for small runs or custom designs since they eliminate the need for expensive screen setups. In contrast, screen printing becomes more economical with larger quantities due to lower ink costs per item.

What material compatibility should be considered when choosing between DTF transfers and screen printing?

Material compatibility is crucial; screen printing primarily works best with cotton and blends, while DTF transfers can adhere to various fabrics, including cotton, polyester, and blends, offering more flexibility for diverse custom apparel options.

How does the environmental impact of DTF printing compare to screen printing?

The environmental impact of DTF printing tends to be lower as it often uses less water and fewer chemicals than screen printing. Furthermore, advancements in eco-friendly inks for DTF enhance its appeal for environmentally conscious consumers looking for sustainable garment decoration methods.

| Key Factors | DTF Transfers | Screen Printing |

|---|---|---|

| Quality and Durability | High-resolution prints, improved durability with recent advancements. | Bright and durable prints, but may fade without proper curing. |

| Cost-Effectiveness | More economical for small batches, lower upfront costs. | More cost-effective for large runs, but higher setup costs for small orders. |

| Speed and Efficiency | Quick turnaround for small batches, straightforward setup. | Time-consuming setup, but rapid production for large orders. |

| Material Compatibility | Compatible with cotton, polyester, and blends. | Primarily for cotton, limited options for synthetics. |

| Environmental Impact | Eco-friendly inks are used; less water and chemicals. | Utilizes more water and chemicals during the printing process. |

Summary

DTF transfers vs. screen printing is a critical decision point for businesses in garment printing. Both methods offer distinct advantages and limitations that can significantly influence the final choice. DTF transfers provide higher resolution printing, faster setup for smaller orders, and lower initial costs, making it an excellent choice for custom apparel. In contrast, screen printing is favored for large production runs thanks to its durability and vibrant results, although it requires a more complex setup and can have higher upfront expenses. Several factors such as production scale, material compatibility, and environmental considerations must be evaluated by businesses to ensure the optimal printing method is chosen. Overall, DTF technology’s evolution positions it as a strong competitor in the market, especially for those favoring flexibility and rapid turnaround.