DTF Transfers: Unlocking Secrets for Your Business Success

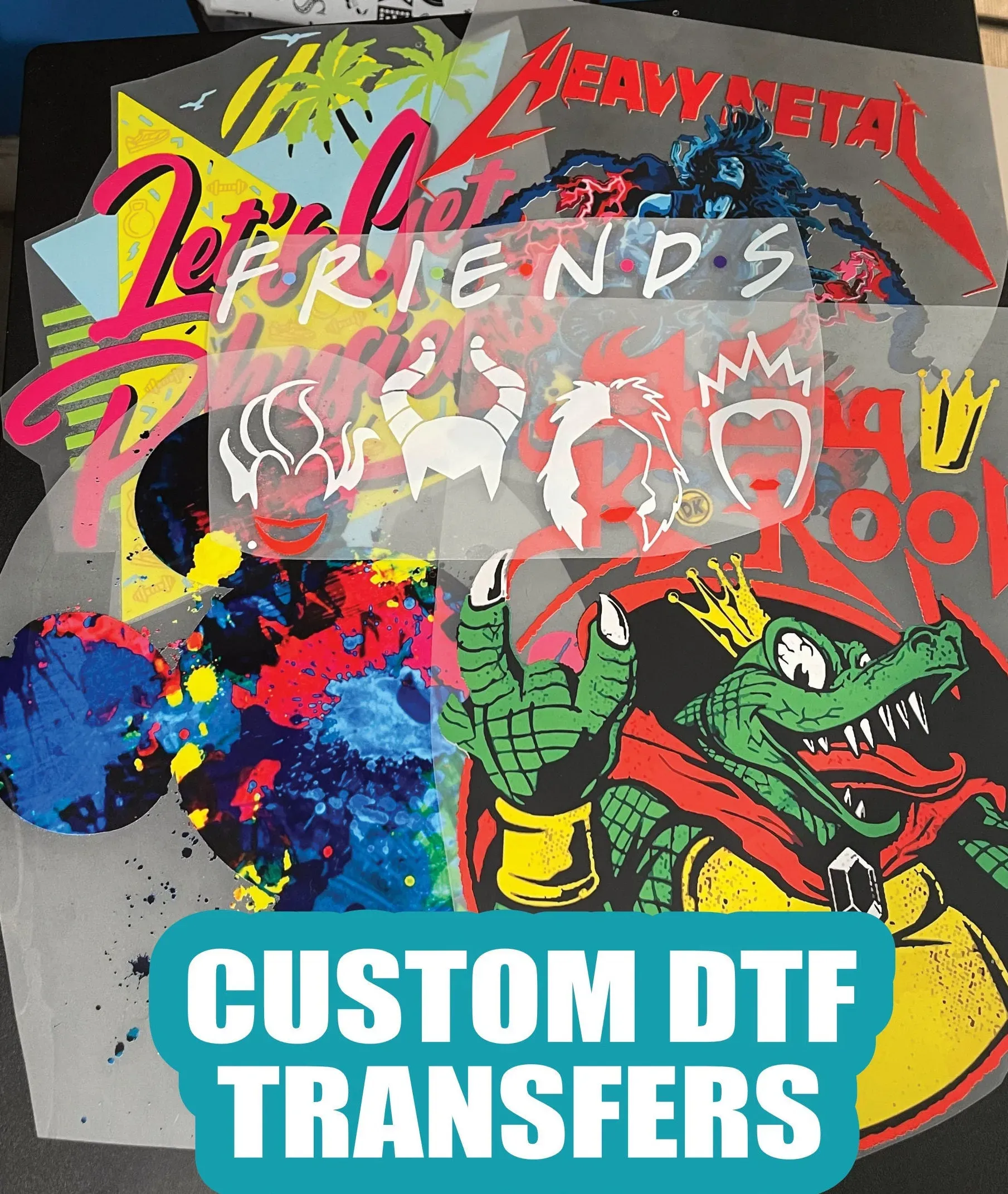

DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom printing industry, offering businesses a modern solution for producing high-quality designs. With innovative DTF printing technology, companies can create intricate, vibrant prints that not only grab attention but also ensure longevity and durability. This method streamlines the printing process, making it an ideal choice for print-on-demand services that cater to rapid market demands. As more entrepreneurs recognize the efficiency and versatility of a DTF printer, the application of DTF transfers in various sectors is leading to an exciting transformation in product offerings. In this ever-evolving landscape, understanding DTF transfers will empower businesses to enhance their competitiveness and satisfy customer needs more effectively.

In the realm of custom apparel and printing solutions, Direct-to-Film printing has emerged as a dynamic alternative to traditional methods. This innovative technique utilizes specialized film for direct ink application, facilitating impressive print quality that meets modern consumer expectations. Businesses looking to expand their services or enter the competitive market of personalized products can significantly benefit from embracing the advantages of DTF printing. By leveraging advanced printing machinery and exploring the capabilities of a DTF printer, entrepreneurs can provide stunning designs that stand out in an oversaturated marketplace. Ultimately, the adoption of DTF transfer methods fosters a fresh approach to custom printing, opening new avenues for innovation and creativity in product design.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology revolutionizes the custom printing industry by streamlining the transfer process. Unlike traditional printing methods, DTF involves creating prints on a special film that can be easily applied to various materials. This flexibility allows businesses to offer a wide range of customizable products, appealing to diverse customer needs. With a DTF printer, companies can produce intricate designs with vibrant colors, making it an indispensable tool for any custom printing business.

The technology behind DTF printing has come a long way, evolving to incorporate advanced ink formulations and printing techniques. This innovation enhances print durability, ensuring that garments and other items maintain their aesthetic appeal even after numerous washes. As such, businesses adopting DTF transfers can provide quality that meets modern consumer expectations, setting themselves apart from competitors who rely on outdated printing methods.

The Versatility of DTF Transfers

One of the most significant advantages of Direct-to-Film (DTF) transfers is their remarkable versatility. DTF technology can be applied to various substrates, including cotton, polyester, leather, and even hard surfaces like wood or metal. This flexibility opens up opportunities for custom printing businesses to expand their product offerings beyond apparel to include home decor, promotional items, and personal accessories.

Moreover, DTF transfers accommodate both small batch orders and large-scale production due to their efficiency. Businesses can cater to individual customer requests while also fulfilling bulk orders without compromising on quality. This adaptability is particularly beneficial in the print-on-demand sector, where rapid delivery and diverse product choices are essential for success.

Cost Benefits of DTF Transfers for Small Businesses

Investing in Direct-to-Film (DTF) printing technology can lead to significant cost savings for small businesses in the custom printing industry. Traditional methods, such as screen printing, often require hefty initial investments in equipment and materials. In contrast, DTF printing necessitates less upfront capital, allowing companies to allocate funds more effectively. Additionally, DTF transfers reduce the need for expensive screens and set-up costs, as the process is primarily digital.

Another cost advantage of DTF transfers is their ability to minimize waste. Since DTF printers produce designs directly onto film, there is less ink loss compared to other printing methods. Furthermore, businesses can adjust their designs without the need for extensive reprints, leading to efficient resource utilization. These financial benefits empower small business owners to reinvest savings into other areas of their operations, such as marketing or expanding product lines.

Enhancing Quality with DTF Printing

The quality of prints produced through Direct-to-Film (DTF) technology is one of its most appealing features. DTF transfers utilize high-quality inks that provide exceptional color vibrancy and sharpness, resulting in eye-catching designs that stand out in the competitive custom printing market. This capability enhances customer satisfaction, as end-users receive products that look professional and are visually striking.

In terms of durability, DTF transfers are designed to withstand multiple washes without fading or cracking, a common issue faced by traditional prints. Businesses that prioritize quality can build their reputation on offering long-lasting products, thereby increasing customer loyalty and repeat purchases. This focus on quality is essential for sustainable growth, particularly in a landscape where consumers are increasingly discerning about the products they buy.

Implementing DTF Technology in Your Workflow

To fully leverage the advantages of Direct-to-Film (DTF) transfers, businesses must consider integrating DTF technology into their existing workflows. Starting with investing in a reliable DTF printer and heat press equipment is crucial. Brands such as Insta Graphic Systems provide cutting-edge solutions that can meet the demands of modern printing operations. By choosing the right equipment, businesses can ensure optimal print quality and efficiency.

Additionally, training staff on DTF technology is essential for maximizing productivity. Adequate training helps employees understand the nuances of operating DTF printers and applying transfers correctly. By establishing a knowledgeable team, businesses can minimize errors and enhance overall printing capabilities. This step is vital for maintaining quality control and achieving high customer satisfaction.

Future Trends in DTF Printing Technology

The future of Direct-to-Film (DTF) transfers looks promising, with continual advancements in printing technology driving innovation in the custom printing sector. As manufacturers seek to improve print quality and efficiency, businesses can expect more robust DTF printers with enhanced features that cater to evolving market demands. Moreover, as the industry embraces sustainability, advancements such as eco-friendly inks will further appeal to environmentally conscious consumers.

Additionally, the expansion of the print-on-demand market will likely fuel the growth of DTF technology. With the increasing consumer demand for personalized products, businesses that adopt DTF transfers can capitalize on this trend by quickly responding to customer preferences. As technology continues to evolve, companies that stay ahead of these developments will be well-positioned to thrive in the competitive landscape of custom printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film that can be heat pressed onto various materials, including garments. The process allows for complex designs and vibrant colors, providing better wash durability compared to traditional printing methods like screen printing.

Why should my custom printing business invest in DTF printing technology?

Investing in DTF printing technology can significantly enhance the quality and efficiency of your custom printing business. DTF transfers allow for versatile applications on different materials, high durability of prints, and a simplified production process, ultimately meeting customer demands more effectively.

What are the advantages of using a DTF printer for custom designs?

Using a DTF printer provides several advantages, such as the ability to create high-quality designs with vivid colors that last through multiple washes. The versatility of DTF printing allows businesses to work on various surfaces, thus expanding their product offerings in the custom printing market.

How does DTF printing technology differ from traditional printing methods?

DTF printing technology differs from traditional methods like screen printing in that it directly applies designs onto a film first, which are then transferred onto the final surface. This process results in better durability, quality of prints, and reduced setup times, making it ideal for on-demand production.

What should I consider when investing in a DTF printer for my business?

When investing in a DTF printer, consider the printer’s quality, efficiency, and the support provided by the manufacturer. Research brands like Insta Graphic Systems for reliable technology, and ensure that the printer meets your specific business needs and workflow requirements.

Can DTF transfers work on all types of materials?

Yes, DTF transfers are highly versatile and can be applied to a wide range of materials, including different fabrics and hard surfaces. This capability allows businesses to offer custom printing services on various products, expanding their market opportunities.

| Key Point | Details |

|---|---|

| What Are DTF Transfers? | A method involving printing designs on a special film that can be heat pressed onto various materials, offering versatility and better wash durability than traditional printing methods. |

| Key Innovations in DTF Technology | 1. Insta DTF Launch: A new product by Insta Graphic Systems promising vibrant prints. 2. Compact DTF Printers: Tailored for small businesses, launched by AM.CO.ZA. 3. Industry Expos: Events like DTF Expo educate about advancements in DTF printing. |

| Benefits of DTF Transfers | Versatility, Quality and Durability, Efficiency in production. |

| How to Implement DTF Transfers | 1. Invest in Quality Equipment. 2. Train Your Team. 3. Develop a Marketing Strategy. |

| The Future of DTF Transfers | DTF transfers are expected to grow with increasing innovation and customer education, highlighting their potential in the evolving printing industry. |

Summary

DTF Transfers are revolutionizing the custom printing landscape by providing businesses with a versatile and efficient method for producing high-quality designs. As companies embrace this innovative technology, they can enhance their product offerings and meet customer demands more effectively. Understanding the key benefits of DTF Transfers, from their durability to the ability to print on a variety of materials, is crucial for any business looking to thrive in a competitive market. By investing in the right equipment and training, businesses can harness the full potential of DTF Transfers, ensuring they remain at the forefront of the custom printing industry.