DTF vs. DTG Printing: Choosing the Best Method for Business

When comparing DTF vs. DTG printing, it’s important to understand how these two popular methods for custom apparel printing stand apart. Direct to Film (DTF) printing utilizes a transfer film that allows for versatile applications on a variety of fabrics, offering businesses the flexibility they need in today’s competitive market. In contrast, Direct to Garment (DTG) printing employs advanced inkjet technology to create high-quality designs directly on garments, making it ideal for intricate details and vibrant colors. Both printing techniques have unique advantages that can significantly influence business decisions, from production costs to material compatibility. By examining the key differences and benefits of these printing methods, entrepreneurs can make informed choices tailored to their specific needs in the world of printing methods comparison.

In the realm of custom clothing production, the discussion often revolves around the merits of Direct to Film (DTF) and Direct to Garment (DTG) techniques. While DTF offers the capability to print on a multitude of fabric types, DTG provides a superior finish for designs loaded with detail and richness. These contrasting approaches to printing fabric underscore the importance of choosing the right technique based on business objectives and the desired final product. As both methods evolve, they present distinct opportunities for entrepreneurs looking to carve a niche in custom apparel. Understanding these alternative printing methods is crucial when considering the most effective strategies for your business operations.

The Basics of Direct to Film (DTF) Printing

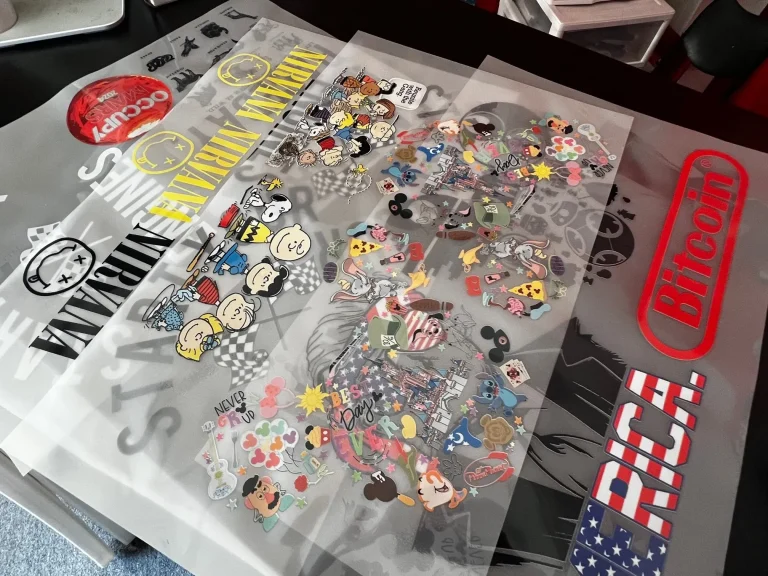

Direct to Film (DTF) printing has emerged as a revolutionary method for transferring designs onto fabric. This technique utilizes special transfer films that allow for vibrant and durable prints. The process starts with printing a design in reverse on the transfer film, followed by a heat press application that transfers the design onto the fabric. One of its defining features is its adaptability to various fabric types, from cotton to polyester blends, making it a favored choice for businesses seeking to diversify their garment offerings.

However, the DTF printing method requires a basic understanding of equipment and materials to achieve high-quality results. It involves certain complexities, such as accurate temperature and pressure settings during the transfer process. For businesses considering DTF, it’s crucial to weigh these operational details against the overall benefits, including its cost-effectiveness for small batch productions.

Frequently Asked Questions

What are the main differences between DTF and DTG printing?

DTF vs. DTG printing primarily differs in their application methods and material compatibility. DTF, or Direct to Film printing, involves transferring ink from a film to the garment through a heat press, and works well on various fabrics. In contrast, DTG, or Direct to Garment printing, utilizes inkjet technology to print directly onto the fabric, mainly suited for cotton or cotton-blend materials.

Which printing method is more cost-effective for small batch custom apparel printing?

When considering DTF vs. DTG printing, DTF printing tends to be more cost-effective for small batch custom apparel printing. It requires lower initial setup costs and allows for versatile fabric use, making it an ideal choice for businesses with limited production runs.

Can DTF printing be used on a variety of fabrics compared to DTG?

Yes, in the DTF vs. DTG printing comparison, DTF printing is noted for its versatility with materials. It can print on various fabrics like cotton, polyester, and blends, whereas DTG printing is primarily optimized for cotton or cotton-blend textiles.

Which printing method produces higher quality images, DTF or DTG?

In the realm of printing methods comparison, DTG printing is known for delivering high-quality, detailed images, making it perfect for intricate designs. DTF printing, while durable, generally does not achieve the same level of detail as DTG.

What should businesses consider when choosing between DTF and DTG printing?

When deciding between DTF vs. DTG printing, businesses should evaluate their target market, the types of fabrics they intend to use, production scale, and budget constraints. Each method aligns with different operational goals and printing needs.

Are there environmental benefits to using DTG printing?

Yes, DTG printing often utilizes water-based inks, which are considered more environmentally friendly compared to traditional inks used in some DTF printing processes. This sustainability aspect can be a significant advantage in the custom apparel printing industry.

| Key Feature | DTF Printing | DTG Printing |

|---|---|---|

| Definition | Transfers designs printed on film to fabric using heat press. | Uses inkjet technology to print designs directly onto garments. |

| Advantages | – Versatile for multiple fabrics. – Durable prints resistant to fading. – Cost-effective for small runs. |

– High-quality, detailed prints. – No minimum order requirement. – More environmentally friendly with water-based inks. |

| Disadvantages | – High initial equipment costs. – Complex transfer processes. |

– Limited to cotton and blends. – Higher ink costs. |

| Ideal For | Businesses with diverse fabric needs, suitable for promotional items. | Fashion-forward markets requiring high-quality prints for custom designs. |

Summary

DTF vs. DTG printing involves evaluating which method better suits your business’s unique requirements. DTF printing is recognized for its versatility and suitability for various fabrics, making it ideal for businesses looking to offer a diverse range of products. In contrast, DTG printing excels in delivering high-quality, intricate designs, particularly preferred in the fashion industry. Assess your target market, production scale, and budget to determine which printing method aligns with your business goals, ensuring you make an informed choice that enhances your operational effectiveness.