DTF Transfers Explained: Your Beginner’s Guide to DTF Printing

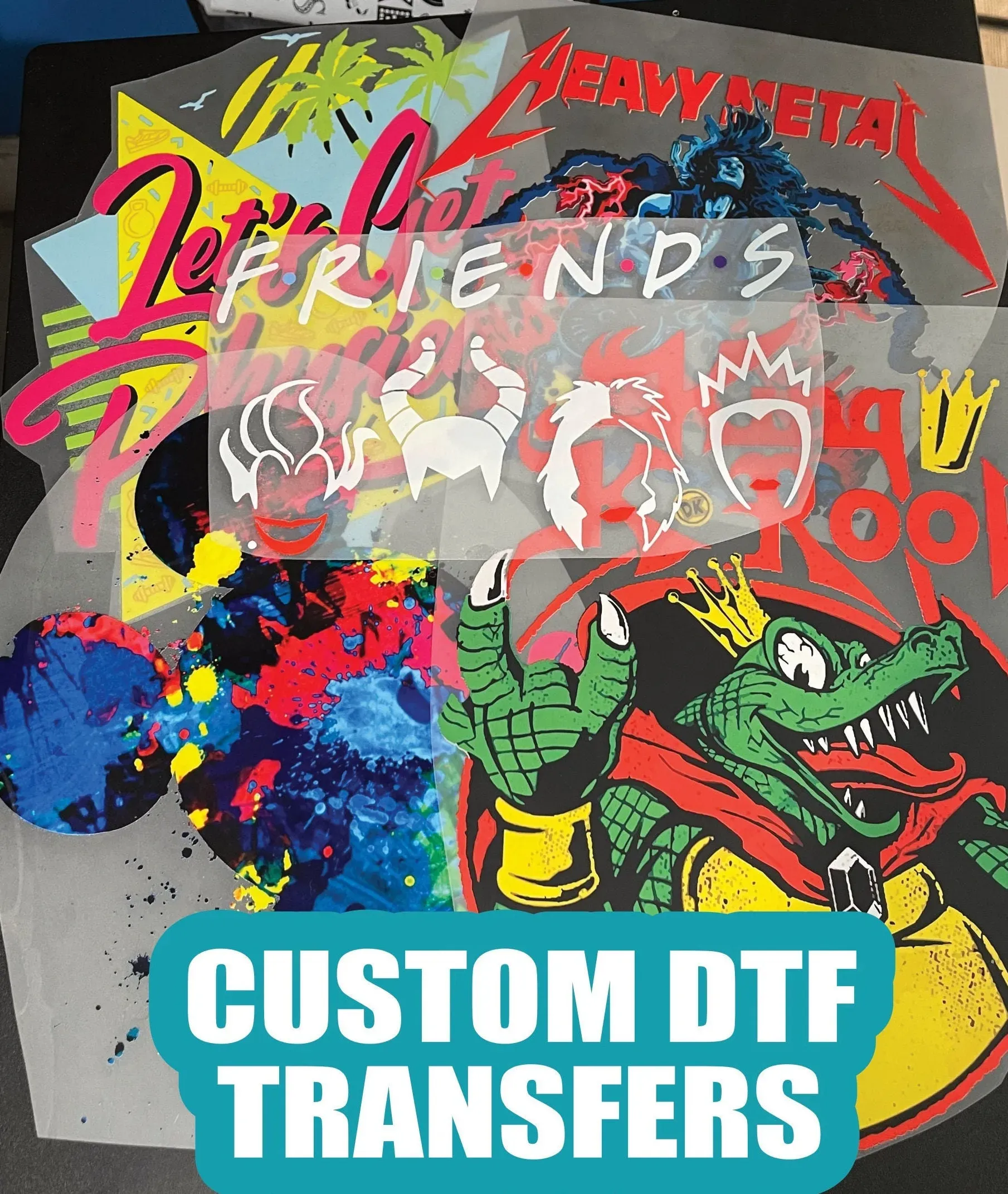

DTF transfers, or Direct-to-Film transfers, are revolutionizing the garment printing landscape, offering an efficient and versatile solution for designers and businesses alike. This innovative method allows for vibrant colors and intricate designs, making it an attractive choice compared to traditional garment printing techniques. With the surge in popularity of Epson DTF printers and their unparalleled performance, more professionals are embracing DTF printing benefits, realizing the potential for both creativity and profit. It’s a key technique for those keen to enter the printing world, including beginners, as it adapts to various fabric types seamlessly. As demand grows, understanding the mechanics behind DTF transfers becomes crucial for anyone looking to leverage this cutting-edge technology in their projects.

Exploring alternative approaches to garment decoration, Direct-to-Film (DTF) method stands out as a beacon of innovation in modern textile printing. This transfer technique, which involves applying digital designs onto specialized film before heat pressing them onto fabrics, enhances the printing capabilities of apparel decorators. With notable advancements in printing technology, including the release of new Epson printers tailored for DTF, this method is becoming synonymous with quality and efficiency. Newcomers can easily dive into this trend with accessible equipment and resources, paving the way for artistic expression and professional growth. As the textile industry embraces diverse garment printing techniques, DTF emerges as a vital tool for creators and businesses aiming for exceptional results.

Understanding DTF Printing: An Overview

Direct-to-Film (DTF) printing is rapidly changing how designs are processed for various fabrics. The process involves printing a digital image onto a transparent film, which can then be transferred to a variety of materials through the application of heat and pressure. This method is known for its capability to produce vibrant colors and intricate designs, positioning itself as a preferred choice among modern garment decorators. As businesses evolve to meet customer demands for unique and customizable products, understanding DTF printing is crucial for staying competitive in the textile industry.

In essence, DTF printing bridges the gap between traditional screen printing and digital printing. It grants users the flexibility to utilize a wider range of fabrics and allows for detailed designs that were once challenging to achieve with conventional printing methods. Whether it’s T-shirts, hoodies, or other fabric items, DTF printing offers a versatile solution for both small-scale and large-scale production, providing exceptional quality prints that stand the test of time.

The Benefits of DTF Transfers for Businesses

One of the primary benefits of DTF transfers is the class of versatility that it brings to the table. Unlike traditional methods, DTF printing allows entrepreneurs to apply high-quality designs to various fabric types, including cotton, polyester, and blends. This adaptability makes it an excellent choice for businesses of all sizes, whether they are looking to produce one-off custom pieces or larger batches of apparel. As consumer tastes evolve, the ability to provide personalized and unique garments can significantly enhance customer satisfaction.

Moreover, DTF transfers are not only versatile but also cost-effective. The process minimizes material waste through print-on-demand strategies, meaning businesses only produce the quantity needed when orders come in. This lean manufacturing approach is particularly advantageous for small businesses that may face financial constraints, making DTF printing an attractive option that supports sustainable practices while maximizing output.

Epson DTF Printers: Pioneering Quality and Efficiency

Epson’s recent launch of the SureColor G6070 DTF printer marks a pivotal development in the garment printing landscape. This state-of-the-art equipment is tailored for professionals looking to elevate their printing capabilities. By integrating advanced printing technology and user-friendly features, Epson aims to enhance efficiency and quality in the DTF printing process, catering to a wide range of users from hobbyists to established printing businesses.

Furthermore, the reliability and performance of Epson DTF printers are complemented by their ability to deliver stunningly vibrant colors. Since accuracy in color reproduction is vital in the fashion industry, Epson’s new technology ensures that even complex gradients and details are captured perfectly. As more companies invest in such innovative machines, the overall standard for DTF printing continues to rise, further solidifying its place as a dominant technique in garment decoration.

Getting Started with DTF Printing: A Beginner’s Guide

For anyone contemplating a foray into DTF printing, it’s essential to start with the right basics. Beginners are advised to acquire a quality DTF printer, heat press, and specialized DTF transfer films to kickstart their journey. Many suppliers offer starter kits that can simplify the onboarding process, ensuring that newcomers have all the necessary components to begin printing.

Additionally, learning resources abound for those new to the DTF printing process. Comprehensive training sessions, online tutorials, and community forums can significantly ease the learning curve. By investing some time in developing design skills and understanding the nuances of DTF printing, newcomers can establish a solid foundation that will ultimately enhance their creativity and ability to meet consumer demand.

Durability and Longevity of DTF Transfers

One of the standout features of DTF transfers is their durability. Unlike some traditional printing methods that may fade or crack over time, prints produced through DTF technology are designed to withstand the rigors of everyday usage. This durability translates into a higher value for customers, ensuring that garments remain vibrant wash after wash, which is critical in maintaining customer satisfaction.

The longevity of DTF prints not only enhances customer loyalty but also reduces the need for reprints or replacements, leading to long-term savings for businesses. With the increasing consumer preference for high-quality products, understanding and leveraging the durability of DTF transfers can provide a competitive edge in the saturated apparel market.

The Future of DTF Printing: Trends to Watch

The DTF printing market continues to evolve, with exciting trends shaping its future. As technology advances, we can expect to see improvements in speed, efficiency, and print quality. Innovations in ink formulations and printing processes are paving the way for more sustainable practices. Companies that adapt to these upcoming trends will not only enhance their operational efficiency but also meet the growing consumer demand for eco-friendly printing options.

Moreover, as DTF printing becomes more widely adopted, there is a growing community of creators and entrepreneurs who are sharing their insights and best practices. This collaborative environment fosters innovation and skill development, making it easier for newcomers to tap into the potential of DTF printing. Ultimately, the future looks bright for DTF printing as it opens up new avenues for creativity and entrepreneurial opportunities in the textile industry.

Frequently Asked Questions

What are the key benefits of DTF transfers in garment printing?

DTF transfers provide several benefits in garment printing, including versatility in design, durability, and cost-effectiveness. They can be applied to various fabric types, resist cracking and fading, and reduce waste by enabling print-on-demand production.

How do I get started with DTF printing as a beginner?

To start with DTF printing, you’ll need essential equipment such as a DTF printer, heat press, and transfer films. Many companies offer beginner starter kits, and it’s advisable to seek online tutorials or training sessions to master the printing process.

What is the difference between DTF printing and traditional printing methods?

Unlike traditional printing methods like screen printing, DTF printing allows for more intricate designs with vibrant colors. DTF works by printing designs onto a film that is then transferred onto fabric using heat and pressure, offering superior print quality.

What are the latest advancements in DTF printing technology?

Recent advancements include the launch of innovative DTF printers such as Epson’s SureColor G6070, designed for garment decorators, and compact A3 DTF printers that expand accessibility for small businesses and home entrepreneurs in markets like South Africa.

Can DTF printing be applied to all types of fabrics?

Yes, DTF printing is versatile and can be applied to a wide variety of fabrics, including cotton, polyester blends, and more. This adaptability makes it a preferred choice for businesses looking to print across different materials.

Why is DTF printing considered a cost-effective solution for small businesses?

DTF printing is cost-effective because it minimizes waste by allowing businesses to print only what is needed. This on-demand production method is ideal for small to medium-sized runs, helping businesses manage costs efficiently while meeting customer demand.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A method where designs are printed onto a specialized film and then transferred onto fabric using heat and pressure, allowing for intricate designs and vibrant colors. |

| Recent Developments | 1. Epson launches the SureColor G6070 DTF printer for garment decorators in 2025. 2. AM.CO.ZA introduces a compact A3 DTF printer for small businesses in South Africa. 3. EazyDTF expands operations with new large-format printers for quicker service. |

| Advantages of DTF Printing | 1. Versatility: Compatible with various fabric types. 2. Durability: Resistant to cracking, fading, and peeling. 3. Cost-Effective: Reduces waste with on-demand printing. |

| Getting Started with DTF Printing | Essential equipment includes a DTF printer, a heat press, and DTF transfer films. Starter kits and online tutorials are available for beginners. |

Summary

DTF Transfers play a pivotal role in modern textile printing techniques, revolutionizing how designs are applied to fabrics. This innovative method enables businesses to create intricate, high-quality prints with significant durability and color vibrancy, making it a preferred choice for garment decorators. As the DTF market expands, driven by advancements in technology and growing accessibility for small businesses, it holds immense potential for creativity and custom solutions in the textile industry. Entrepreneurs and designers alike must stay updated on the latest trends and hone their skills to thrive in this dynamic environment.