DTF Transfers: Enhancing Your Merchandise Line Effectively

DTF transfers, or Direct to Film transfers, are revolutionizing the way businesses approach custom merchandise printing. This innovative technology allows for high-resolution designs to be printed directly onto a special film, which can then be applied to a wide range of materials including cotton and polyester. As the demand for unique and personalized products grows, understanding the benefits of DTF printing is essential for any company looking to enhance their merchandise line. With advantages such as superior durability, vibrant color reproduction, and quick turnaround times, DTF transfer technology is quickly becoming a favored solution in merchandise production. In this article, we’ll delve into how DTF transfers can elevate your offerings and provide insights into the latest advancements in this exciting printing method.

In the modern landscape of merchandise production, Direct to Film printing has emerged as a game-changer, providing businesses with the tools needed to create stunning custom apparel. By utilizing DTF technology, companies can produce intricate designs that cater to the diverse tastes of their customers, seamlessly integrating into their product lines. This approach not only enhances the quality of merchandise but also responds to market demands for personalization and rapid production. As the printing industry evolves, alternative methods like film transfers unveil a world of opportunities for both large enterprises and small businesses alike, ensuring they remain competitive in a dynamic market. Here, we will explore the multitude of benefits associated with this innovative printing technique and its potential to transform merchandise offerings.

Understanding the Mechanics of DTF Transfers

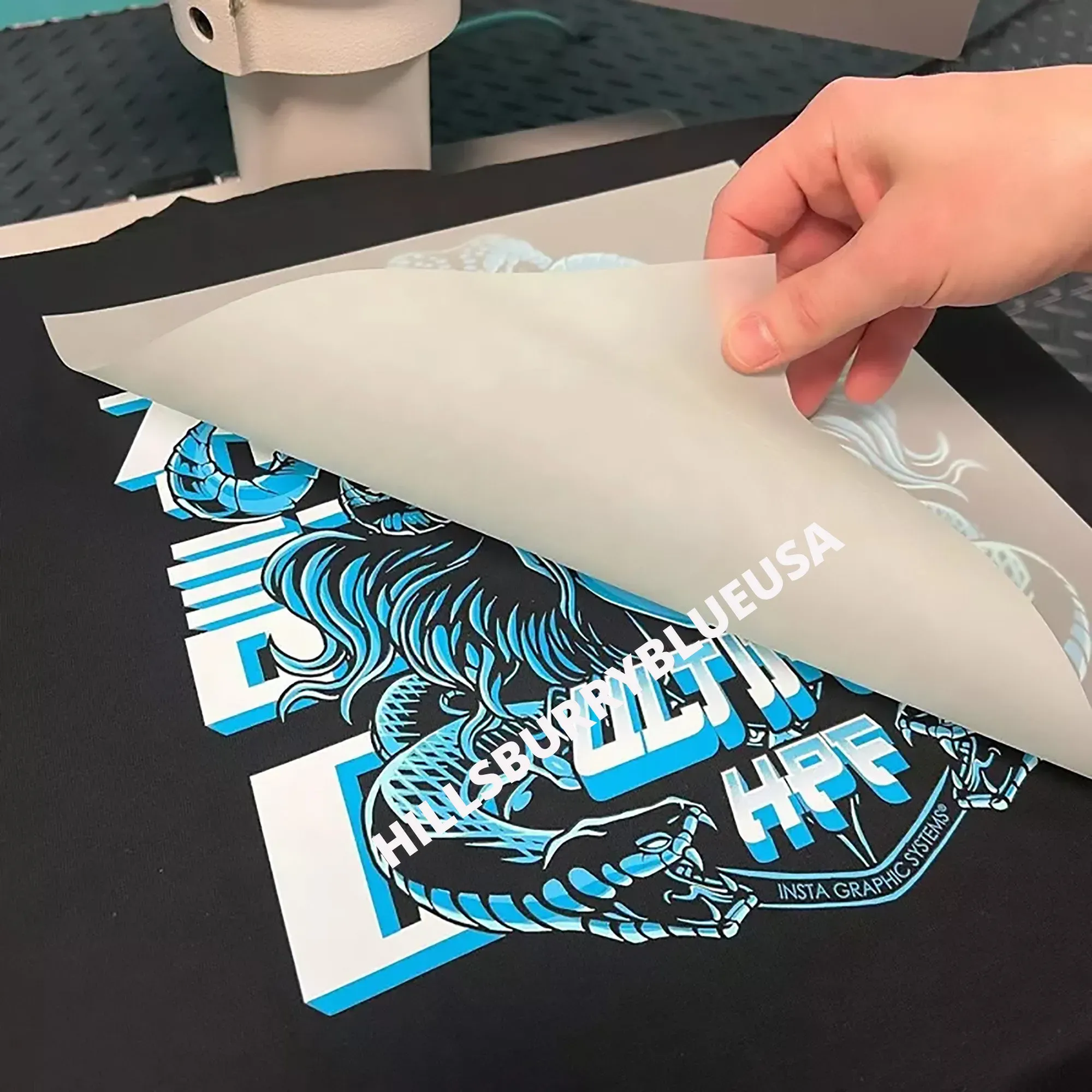

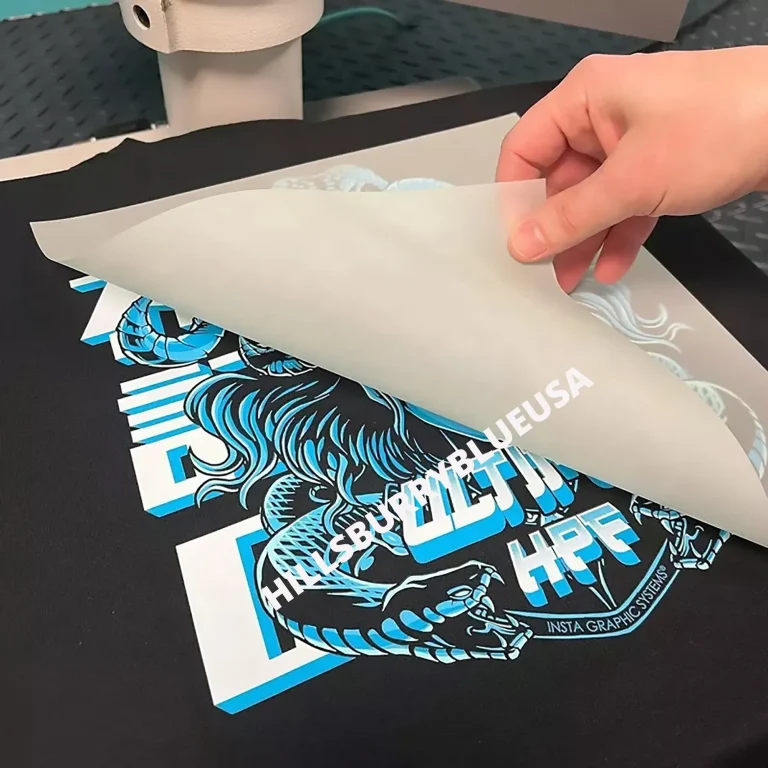

Direct to Film (DTF) transfers have revolutionized the printing industry by offering a versatile solution for custom merchandise printing. This process involves printing designs onto a film using state-of-the-art printers, allowing the design to be transferred onto various materials through heat application. Not only does it accommodate a range of fabrics, from cotton to polyesters and blends, but it also ensures that intricate designs maintain their quality once transferred. By understanding how DTF works, businesses can better appreciate its potential and integrate it into their production workflows.

The technology behind DTF transfers is continuously advancing, making it easier for businesses to produce high-quality prints with fewer resources. DTF utilizes an advanced ink system that allows for vibrant colors and excellent durability, leading to merchandise that can endure washing and wear without fading. This capability is especially advantageous for brands looking to expand their offerings with custom designs that resonate with their audience.

The Benefits of DTF Printing for Merchandise Lines

Businesses integrating DTF transfers into their production lines can expect numerous benefits that directly impact profitability and customer satisfaction. First and foremost, DTF printing provides high durability and vibrant colors that make the end product appealing. Unlike traditional print methods, DTF allows for detailed artwork that can catch the eye of consumers, making products stand out in a saturated market. Additionally, the flexibility offered by DTF enables brands to customize items, tailoring their product line to specific demographics or trends.

Moreover, DTF transfers bring cost-effectiveness into the equation, as they reduce waste and optimize inventory management. With the ability to print on-demand, businesses can fulfill small custom orders without the financial burden of unsold stock. This is particularly appealing for smaller enterprises and freelancers who may struggle with high upfront costs typically associated with mass production.

Recent Innovations in DTF Technology

Recent developments in DTF technology have made it more accessible and efficient for businesses. Innovations such as Snuggle’s new trade service allow companies to produce thousands of DTF transfers daily, drastically increasing production capacity. This shift not only enhances the speed of order fulfillment but also addresses the growing demand for unique and customized merchandise. As businesses increasingly recognize the value of DTF, these technological advancements will likely play a crucial role in streamlining operations and meeting customer expectations.

Furthermore, the introduction of web-to-print platforms specifically designed for DTF orders simplifies the ordering process. Companies can now place orders online, significantly reducing the time taken from design to delivery. The ease of use associated with these platforms empowers businesses, allowing them to focus on creative marketing strategies while ensuring operational efficiency.

Comparing DTF Transfers with Traditional Printing Methods

When comparing DTF transfers to traditional printing methods, the distinct advantages of DTF become apparent. Unlike screen printing, which is often limited to certain fabric types, DTF can be applied to a broad spectrum of materials, thus providing more versatility in product offerings. This advantage enables businesses to cater to varied customer preferences and markets, as they can experiment with different fabrics without compromising on quality.

Additionally, DTF technology requires less setup time than traditional methods, which can be labor-intensive and time-consuming. With DTF, operators can quickly switch between designs, allowing for seamless production of diverse items. This flexibility is a game-changer for businesses looking to enhance their merchandise lines while maintaining high-quality output.

Implementing DTF Transfers in Your Business

For businesses keen on incorporating DTF transfers, the first step is to invest in the right technology. With options like compact A3 DTF printers now on the market, even small companies can access professional-grade printing capabilities. These printers are user-friendly and designed for those with limited space, making them an ideal choice for startups and freelancers looking to establish their custom merchandise printing operations.

Additionally, exploring partnerships with larger DTF service providers can significantly enhance production capabilities. By collaborating with established companies, smaller businesses can leverage high-volume production without the need for hefty capital investments, thus ensuring they can meet the demands of their customers swiftly and effectively.

The Future of Merchandise Production with DTF Transfers

As the future of merchandise production unfolds, the demand for high-quality, customizable products will only continue to grow. DTF transfers stand at the forefront of this evolution, offering innovative solutions that combine speed, flexibility, and quality. With continuous enhancements in technology, businesses utilizing DTF will be well-positioned to adapt to changing market conditions and customer desires.

Moreover, as consumer preferences shift towards personalized products, those businesses that embrace DTF technology will have a competitive edge. By staying ahead of the curve and continuously evolving their offerings, companies can create unique brand identities that resonate with their audience, paving the way for sustained growth and success in the dynamic world of merchandise production.

Frequently Asked Questions

What are the advantages of using DTF transfers in custom merchandise printing?

DTF transfers offer several advantages for custom merchandise printing including high-quality and durable prints, cost-effectiveness through minimized waste, quick turnaround times thanks to innovative web-to-print solutions, and ample customization options that cater to diverse customer preferences.

How does Direct to Film printing differ from traditional methods like screen printing?

Direct to Film (DTF) printing differs from traditional screen printing by allowing for a wider variety of fabrics, including cotton and polyester blends. It utilizes a unique pressing technique that can produce intricate designs, making it more versatile and tailored for modern merchandise production.

What innovations have improved DTF transfer technology recently?

Recent innovations such as Snuggle’s new trade service capable of high-volume production, the introduction of user-friendly web-to-print platforms, and compact DTF printers for small businesses have significantly improved DTF transfer technology, enhancing both efficiency and accessibility for custom merchandise printing.

Can DTF transfers enhance the merchandise line for small businesses?

Yes, DTF transfers can enhance the merchandise line for small businesses by providing high-quality, customizable prints that meet consumer demand. With advancements like compact DTF printers, small enterprises can easily integrate this technology to diversify their product offerings.

What should businesses consider when integrating DTF transfer technology into their production process?

Businesses should consider investing in DTF printing technology, collaborating with service providers for high-volume capabilities, exploring creative design possibilities, and utilizing web-to-print solutions to streamline their production processes and improve efficiency in merchandise enhancement.

What makes DTF transfers a cost-effective option for merchandise production?

DTF transfers are cost-effective due to their ability to minimize waste through on-demand printing, reducing the risk of unsold inventory. Additionally, innovations that enhance production speed contribute to lower operational costs and improved profitability for businesses using this technology.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on a special film that can adhere to various fabrics using heat and pressure. This method is more versatile compared to traditional printing techniques. |

| Recent Developments | Key advancements in DTF technology include Snuggle’s new trade service capable of high-volume prints, a dedicated web-to-print platform, and compact A3 printers aimed at small businesses. |

| Comparison with Other Methods | DTF is more versatile than sublimation, which is limited to certain fabrics. DTF works on a wide range of materials, enhancing customization possibilities. |

| Benefits of DTF Transfers | Advantages include high quality and durability, cost-effectiveness, quick turnaround times, and strong customization options. |

| Integrating DTF into Merchandise Lines | Investing in DTF technology, exploring design options, utilizing web-to-print solutions, and educating staff are essential steps for businesses. |

Summary

DTF Transfers are revolutionizing the merchandise production industry by enabling businesses to create high-quality, customizable products that meet the diverse needs of consumers. This innovative approach harnesses the latest advancements in printing technology, making it easier for companies to diversify their product lines while maintaining efficiency and reducing costs. With the aid of platforms like Snuggle’s web-to-print service, businesses can streamline operations and respond swiftly to market demands, positioning themselves for success in a competitive landscape.